Cathode electrophoretic coating composition and preparation method thereof

A cathodic electrophoretic coating and composition technology, which can be applied to electrophoretic coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as affecting the appearance of coating and yellowing of the upper coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-A

[0045] Preparation Example 1-A: Preparation of Cycloaliphatic Resin

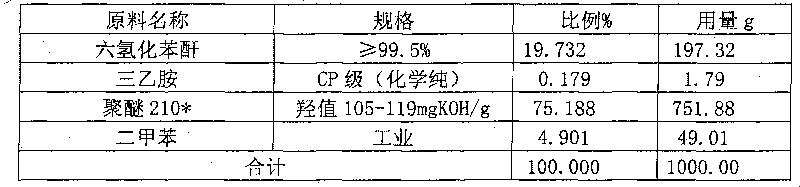

[0046] The composition of each raw material is shown in the table below:

[0047]

[0048] * Polyether 210: produced by Shanghai Gaoqiao Petrochemical

[0049] Preparation process: Put 197.32g of hexahydrophthalic anhydride, 49.01g of xylene, and 210751.88g of polyether into a 2000ml reaction bottle, heat to 130-140°C, and carry out the compounding until the mixture becomes a uniform liquid state; quickly add triethyl Put 1.79g of amine into the reaction bottle; control the temperature at 130-140°C, and carry out the esterification reaction, which takes about 3-4 hours; check the acid value, when the acid value reaches 75±5mgKOH / g, the reaction is complete, and the material is discharged for later use .

preparation example 1-B

[0050] Preparation Example 1-B: Preparation of Cycloaliphatic Resin

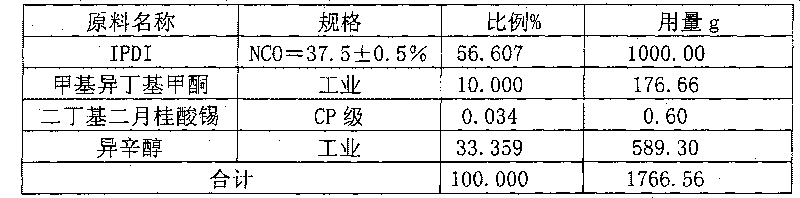

[0051] The composition of each raw material is shown in the table below:

[0052]

[0053] Preparation process: Put 398.26g of IPDI, 100.32g of methyl isobutyl ketone, and 0.04g of phosphoric acid solution into a 2000ml reaction bottle, and heat and stir with nitrogen; Adding time is 2-3 hours, keep the reaction temperature of the material at 50-60°C during the dropwise addition, keep warm for 2 hours after the dropwise addition is completed; Hours; detection - NCO value, when the NCO value ≤ 2mg / g, the reaction is complete, and the material is discharged for later use.

preparation example 1-C

[0054] Preparation Example 1-C: Preparation of Cycloaliphatic Resin

[0055] The composition of each raw material is shown in the table below:

[0056]

[0057] Preparation process: Put 1000.00g of IPDI, 176.66g of methyl isobutyl ketone and 0.60g of dibutyltin dilaurate into a 2000ml reaction bottle; raise the temperature to 50°C, add 589.30g of isooctyl alcohol dropwise evenly, and the dropwise addition is completed Finally, keep warm for 3 hours; check the NCO value, when the NCO value=104-110mg / g, the reaction is complete, and the material is discharged in a clean, dry and well-sealed container for subsequent use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com