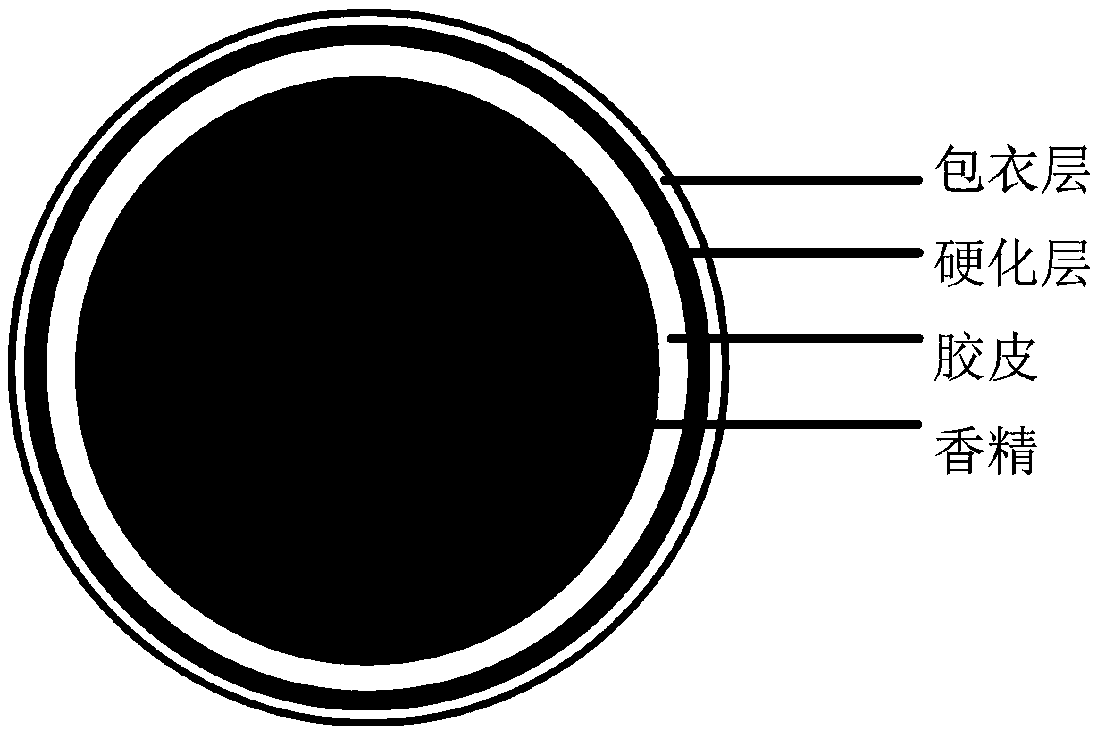

Moisture-proof and embrittling treatment method of cigarette capsules and product obtained by treatment method

A processing method and capsule technology, applied in the application, tobacco, e-liquid filter and other directions, can solve the problems of affecting the use effect of cigarette capsules, not resistant to extrusion, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: Moisture-proof and embrittlement-enhancing treatment of capsules for cigarettes

[0080] The implementation steps of this embodiment are as follows:

[0081] A, preparation of cigarette capsules

[0082] Mix 1.1 parts by weight of carrageenan film-forming agent, 0.3 parts by weight of glycerin plasticizer, 0.2 parts by weight of seaweed polysaccharide copolymer and supplemented to 100 parts by weight of water to obtain a precipitation-free mixed solution, which is prepared by conventional dropping method to obtain the initial Capsules for making cigarettes;

[0083] B. Post-processing of cigarette capsules

[0084] Soak the primary tobacco capsules obtained in step A in saturated potassium sulfate aqueous solution for 3 minutes, then take out the tobacco capsules, put them in a tumbler and dry them with air at room temperature for 3.5 hours to obtain semi-finished cigarette capsules;

[0085] C. Preparation of coating solution

[0086] 12 parts by weig...

Embodiment 2

[0092] Embodiment 2: Moisture-proof and embrittlement-enhancing treatment of capsules for cigarettes

[0093]The implementation steps of this embodiment are as follows:

[0094] A, preparation of cigarette capsules

[0095] 1.4 parts by weight of gum arabic film-forming agent, 0.1 parts by weight of polyethylene glycol plasticizer, 0.4 parts by weight of wheat starch polysaccharide copolymer and supplemented to 100 parts by weight of water are uniformly mixed to obtain a precipitation-free mixed solution, which is prepared by conventional dripping The primary cigarette capsules were prepared by the method;

[0096] B. Post-processing of cigarette capsules

[0097] Soak the primary tobacco capsules obtained in step A in a saturated magnesium carbonate aqueous solution for 5 minutes, then take out the tobacco capsules, put them in a tumbler and dry them by blowing air at room temperature for 3.8 hours to obtain semi-finished tobacco capsules;

[0098] C. Preparation of coatin...

Embodiment 3

[0105] Embodiment 3: Moisture-proof and embrittlement-enhancing treatment of capsules for cigarettes

[0106] The implementation steps of this embodiment are as follows:

[0107] A, preparation of cigarette capsules

[0108] Mix 1 part by weight of malt extract film-forming agent, 0.5 part by weight of sorbitol plasticizer, 0.1 part by weight of pectin polysaccharide copolymer and supplemented to 100 parts by weight of water to obtain a non-precipitating mixed solution, which is prepared by conventional dropping method Obtain the primary tobacco capsules;

[0109] B. Post-processing of cigarette capsules

[0110] Let the primary cigarette capsules obtained in step A be soaked in saturated calcium chloride saline solution for 2 minutes, then take out the cigarette capsules, put them in a tumbler and dry them by blowing air at room temperature for 4.2 hours to obtain semi-finished cigarette capsules ;

[0111] C. Preparation of coating solution

[0112] 10 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure value | aaaaa | aaaaa |

| Pressure value | aaaaa | aaaaa |

| Pressure value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com