Hydrophilic polyethylene microporous membrane and preparation method thereof

A polyethylene microporous membrane, hydrophilic technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of inability to be wetted, non-wetting by liquid, cumbersome and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0034] Wet the polyethylene microporous membrane with DMAC, use a solution composed of 1% PVA, 1% glutaraldehyde and water to coat the polyethylene microporous membrane after the first step of DMAC wetting treatment, let it stand at room temperature for 2 minutes, and then heat it at 70°C Joint treatment for 10 minutes, the other side of the polyethylene microporous membrane after the first surface coating and heat crosslinking treatment is evenly coated with a solution composed of PVA1%, glutaraldehyde 1% and water for the second time, and stand at room temperature for 2min Afterwards, heat at 70°C for 10 minutes of cross-linking treatment, soak in water for 12 hours, dry, and set aside. The obtained contact angle is 35° and the pure water flux is 500L / m 2 h bar hydrophilic modified polyethylene microporous flat membrane.

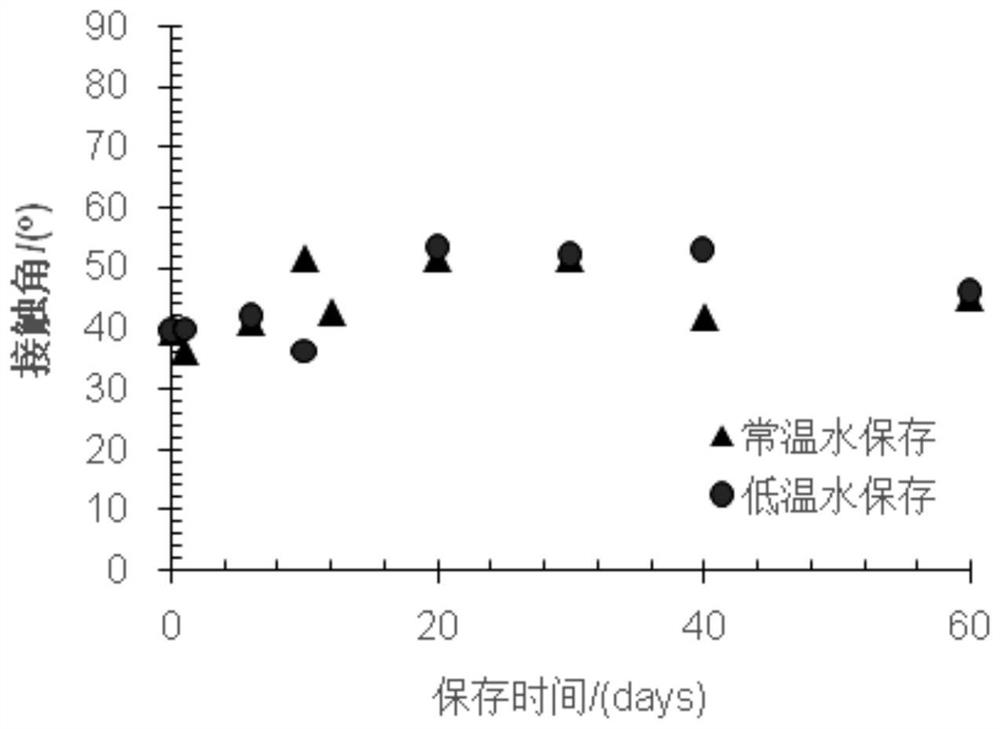

[0035] The membranes prepared in Example 1 were stored in normal temperature water and low temperature water (5°C) respectively. The contact angles of th...

Embodiment example 2

[0037] Wet the polyethylene microporous membrane with DMAC, use a solution composed of PVA1%, glutaraldehyde 10%, DMAC70% and water to coat the polyethylene microporous membrane after the first step of DMAC wetting treatment, and heat it after standing at room temperature for 2 minutes Cross-linking treatment at 80°C for 5 minutes, the other side of the polyethylene microporous membrane after the first coating and thermal cross-linking treatment was evenly coated with a solution composed of 1% PVA, 1% glutaraldehyde and water for the second time, at room temperature After standing still for 2 minutes, heat at 80°C for 5 minutes for cross-linking treatment, put the cross-linked polyethylene microporous membrane into water for 12 hours, dry it, and set it aside. The obtained contact angle is 40° and the pure water flux is 200L / m 2 h bar hydrophilic modified polyethylene microporous flat membrane.

Embodiment example 3

[0039]Wet the polyethylene microporous membrane with DMAC, use a solution composed of 5% PEI, 10% glutaraldehyde and water to coat the polyethylene microporous membrane after the first step of DMAC wetting treatment, let it stand at room temperature for 5 minutes, and then heat it to 60°C After cross-linking treatment for 10 minutes, the other side of the polyethylene microporous membrane after the first surface coating and thermal cross-linking treatment was evenly coated with a solution composed of PEI%, glutaraldehyde 1% and water for the second time, and stood at room temperature After 2 minutes, heat at 60°C for 10 minutes for cross-linking treatment, soak the cross-linked polyethylene microporous membrane in water for 6 hours, dry, and set aside. The obtained contact angle is 45° and the pure water flux is 190L / m 2 h bar surface hydrophilic modified polyethylene microporous flat membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com