Composite catalytic filter material for degrading dioxin at low temperature and preparation method thereof

A technology of catalytic filtration and high temperature resistant filter material, applied in catalyst activation/preparation, chemical instruments and methods, separation methods, etc., can solve problems such as easy chlorine poisoning and deactivation, achieve long service life, maintain original performance and stability performance, excellent low temperature activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

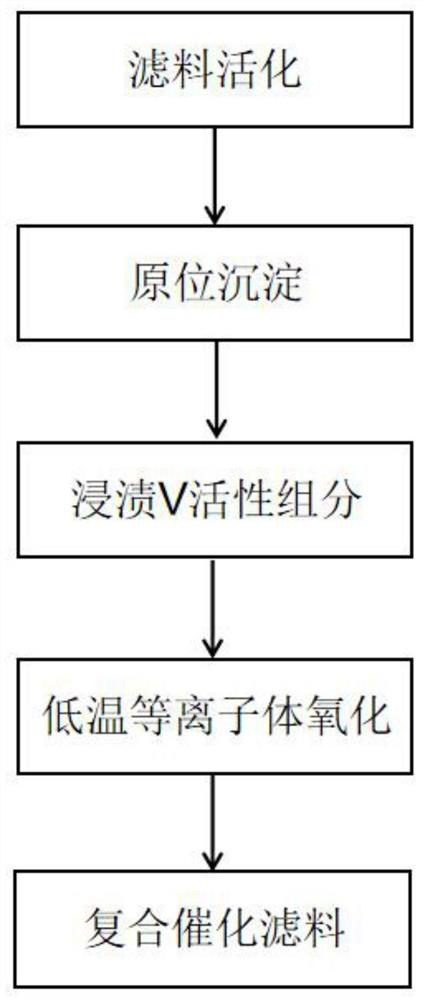

[0034] Such as figure 1 Shown, preparation method of the present invention is as follows:

[0035] (1) Filter material activation: First cut out a polyphenylene sulfide needle felt filter material disc with a diameter of 20mm, wash it three times with deionized water, dry it in an oven at 105°C for 6 hours, and weigh it; weigh 0.0577g Sodium lauryl sulfate powder was prepared into 200 mL of 0.001 mol / L sodium lauryl sulfate solution with deionized water as a solvent, and the dried polyphenylene sulfide disc was immersed in the solution, and ultrasonically activated for 1 h.

[0036] (2) Precipitation in situ: a). Impregnating Ce active components: Weigh 0.3251 g of cerium chloride heptahydrate and add it to the solution obtained in step (1), and stir at room temperature for 12 hours.

[0037] b).KMnO 4 Oxidation: Weigh 1.3790g of potassium permanganate powder, dissolve it in 100mL of deionized water, and prepare a 0.08mol / L potassium permanganate solution, and add 100mL of 0...

Embodiment 2

[0041] (1) Filter material activation: first cut out a polyphenylene sulfide needle felt filter material disc with a diameter of 20mm, wash it three times with deionized water, dry it in an oven at 105°C for 6 hours, and weigh it; weigh 0.2307g Sodium lauryl sulfate powder was prepared into 200 mL of 0.004 mol / L sodium lauryl sulfate solution with deionized water as a solvent, and the dried polyphenylene sulfide disc was immersed in the solution, and ultrasonically activated for 2 hours.

[0042] (2) Precipitation in situ: a): impregnation of Ce active components: Weigh 0.6502 g of cerium chloride heptahydrate and add it to the solution obtained in step (1), and stir at room temperature for 16 hours.

[0043] b): KMnO 4 Oxidation: Weigh 2.7580g of potassium permanganate powder, dissolve it in 100mL of deionized water, and prepare a 0.17mol / L potassium permanganate solution, and add 100mL of 0.17mol / L potassium permanganate solution to step a ) in the resulting solution, stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com