Device for evaporation by utilizing gas moisture content difference

A gas and steam technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of increased heat transfer temperature difference loss, high cost, complex working principle of multi-effect evaporation, etc., and achieve the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

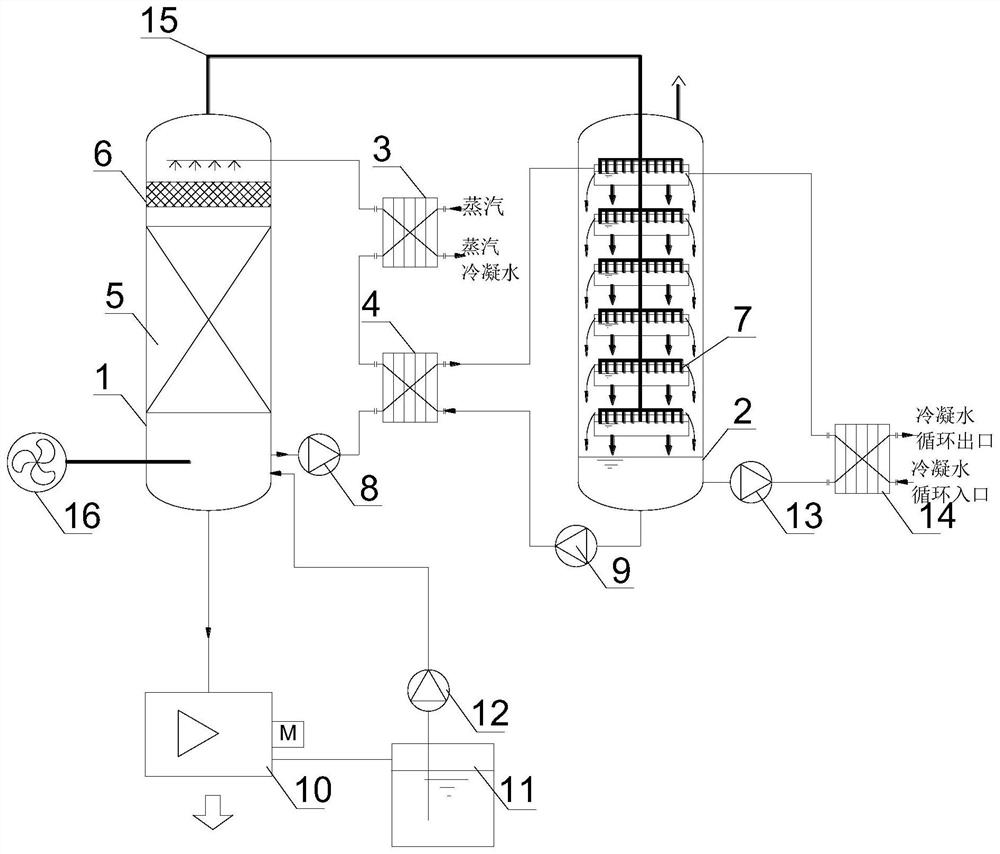

[0036] Please refer to figure 1 , specifically as figure 1 One embodiment of the invention is shown.

[0037] This embodiment provides a device for evaporating by using the difference in humidity of the gas, including a heating tower 1, a cooling tower 2, a centrifuge 10, a centrifuge mother liquor tank 11, and a centrifugal fan 16; the lower part of the heating tower 1 communicates with the centrifugal fan 16. Centrifugal blower 16 sends fresh air into heating tower 1, and the bottom of heating tower 1 communicates with centrifuge 10, and the other end of centrifuge 10 links to each other with centrifugal mother liquor tank 11, and centrifugal mother liquor tank 11 communicates with heating tower 1 bottom; It also includes a heat exchange assembly, the lower part of the temperature rise tower 1 is also communicated with the top of the temperature rise tower 1 through the heat exchange assembly, the temperature rise tower 1 is provided with a special filler 5, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com