Preparation method of colloidal electrolyte for airport ferry vehicle lithium battery

A colloidal electrolyte and shuttle bus technology, which is applied in the field of colloidal electrolyte preparation of lithium batteries, can solve the problems of poor mechanical stability and thermal stability, poor ionic conductivity and electrochemical compatibility, etc., so as to improve interface stability and improve safety. , the effect of reducing group interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

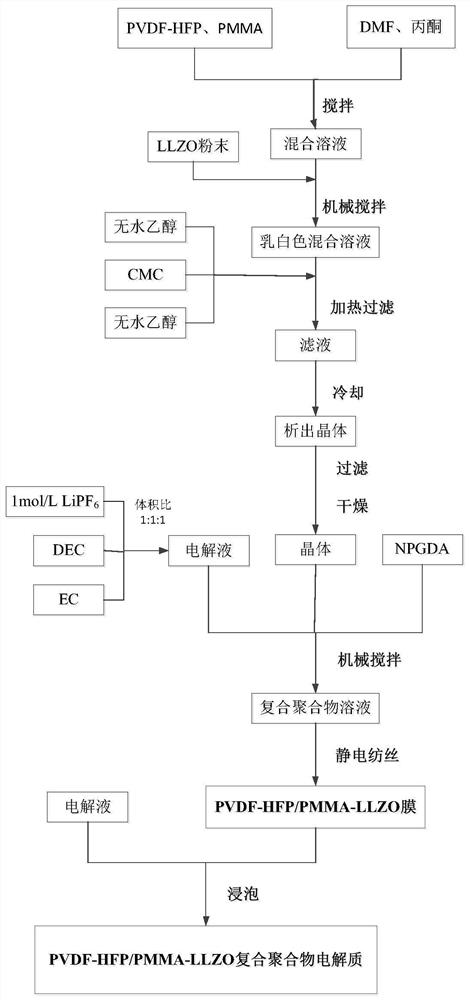

[0045] refer to figure 1 and figure 2 It can be seen that a method for preparing a colloidal electrolyte for an airport shuttle lithium battery comprises the following steps:

[0046] (1) PVDF-HFP and PMMA powders are weighed and dissolved in DMF and acetone solution;

[0047] (2) Add LLZO nanoparticles to the mixed solution after stirring;

[0048] (3) Stir fully for 10-90 minutes to obtain a milky white mixed solution;

[0049] (4) Add CMC powder to the mixed solution and stir fully;

[0050] (5) Add AIBN in the mixed solution as initiator;

[0051] (6) Heat the solution at 60-70°C, filter while it is hot, and cool the filtrate in the refrigerator for 1-3 hours;

[0052] (7) Precipitate crystals, filter again, and dry in a vacuum oven at 25-45°C for 12 hours;

[0053] (8) prepare electrolyte;

[0054] (9) Put the crystal obtained in step (7) into the electrolyte solution obtained in step (8), place it in a magnetic stirrer and stir until completely dissolved;

[005...

Embodiment 1

[0064] 1) Take PVDF-HFP and PMMA powder with a mass ratio of 1:1 with a balance;

[0065] 2) adding a solution of acetone and DMF with a volume ratio of 3:1;

[0066] 3) After stirring evenly with a magnetic stirrer, add LLZO nanoparticles into the mixed solution;

[0067] 4) Fully stir for 20 min to obtain a milky white mixed solution;

[0068] 5) First add CMC to the above solution, and then add AIBN to the mixed solution;

[0069] 6) Heat the solution to 60°C, filter while it is hot, and cool the filtrate in a refrigerator for 2 hours;

[0070] 7) Precipitate crystals, filter again, and dry in a vacuum oven at 25°C for 12 hours;

[0071] 8) prepare electrolyte;

[0072] 9) Add the crystals in step 7) to the electrolyte in step 8), and stir to completely dissolve them;

[0073] 10) Add NPGDA and stir and mix to obtain a composite polymer solution;

[0074] 11) The prepared composite polymer solution is passed through an electrospinning mechanism to obtain a blended fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com