Ultrahigh-speed laser cladding system and laser cladding method

A laser cladding, ultra-high-speed technology, applied in the direction of metal material coating process, coating, additive processing, etc., can solve the problems of low cladding efficiency, achieve the effect of reducing burning optical fiber, high efficiency, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

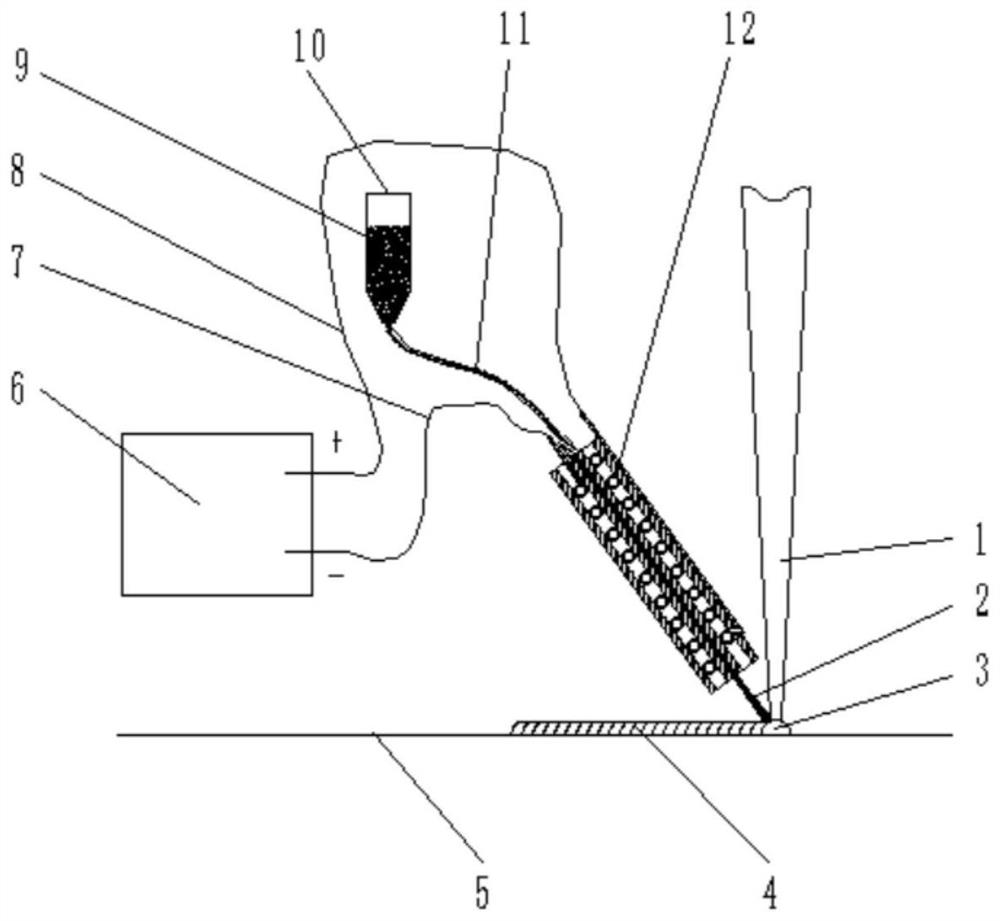

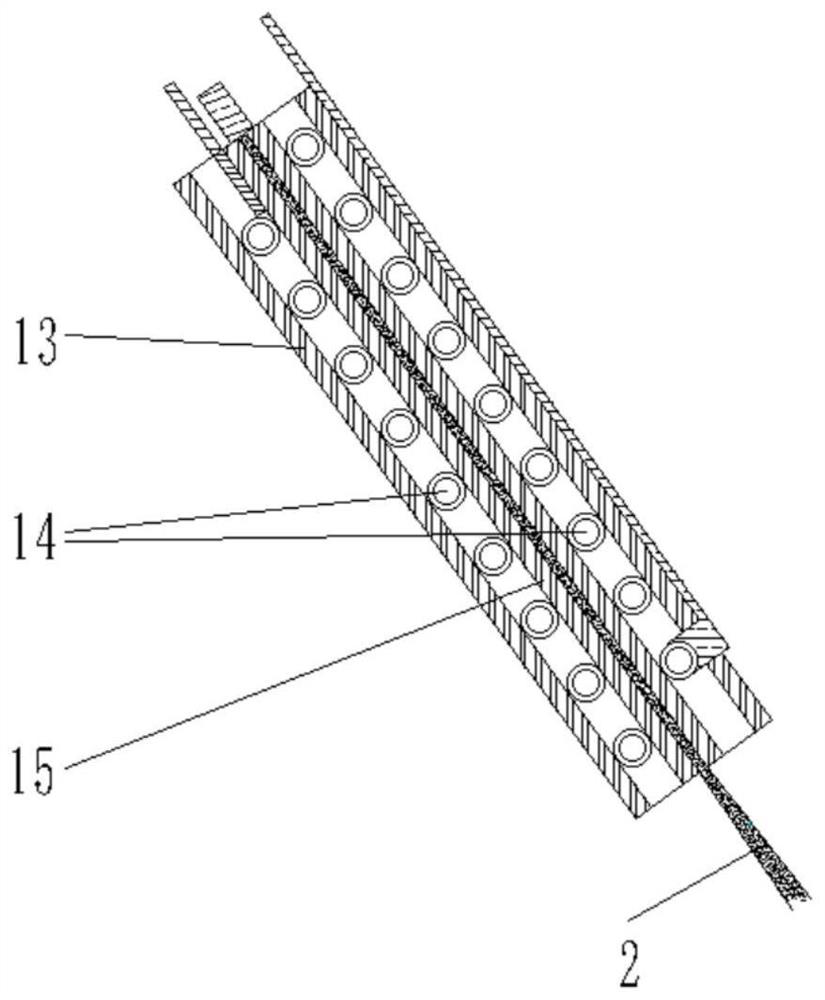

[0048] Embodiment 1 is an embodiment of laser cladding on the piston rod of the hydraulic support cylinder based on the heating of the electromagnetic heating component.

[0049] 1. This embodiment is laser cladding on the surface of the hydraulic support cylinder piston rod (hereinafter referred to as the piston rod). The diameter of the piston rod is 260mm, the length of the cladding area is 1900mm, and the material is 27SiMn.

[0050] 2. The ultra-high-speed laser cladding scheme of the piston rod in this embodiment adopts a 4Kw laser beam, and the spot where the laser beam converges at the position of the molten pool is a circular spot with a diameter of 3 mm. The angle between the laser beam and the inner ceramic tube is adjusted to 25°, the distance from the molten pool to the end face of the inner ceramic tube is 13mm.

[0051] 3. Choose an airborne disc-type powder feeder, the material is 304L stainless steel powder, the powder particle size is 45-150um, put the powder...

Embodiment 2

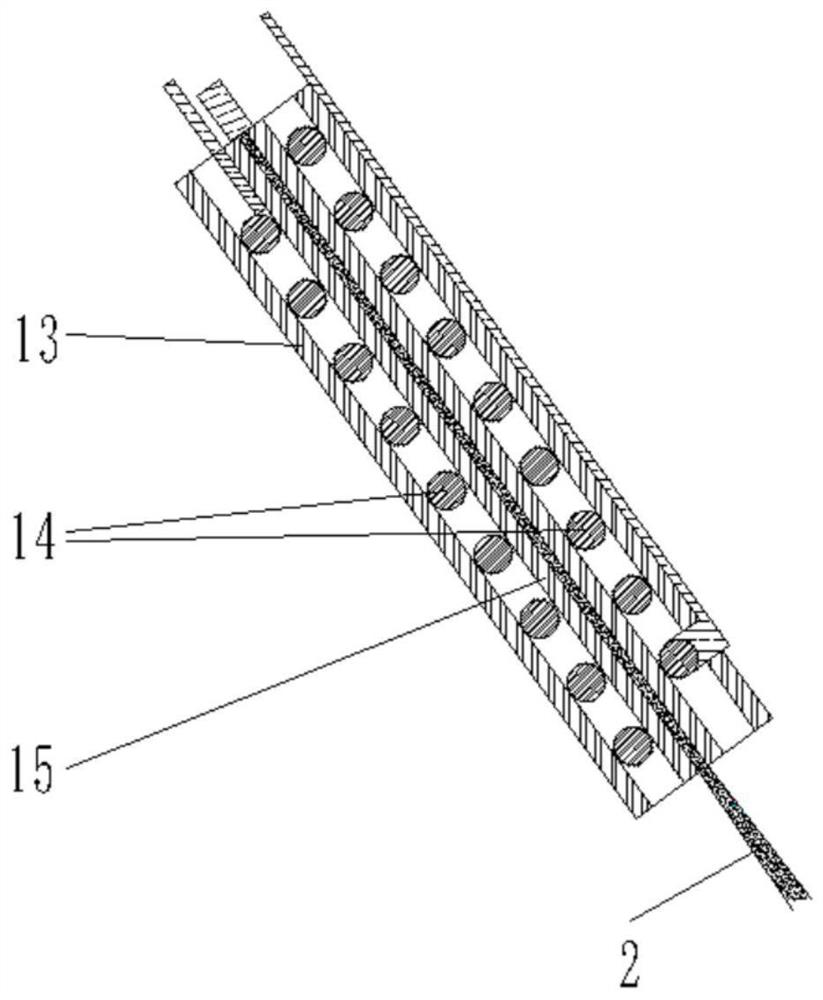

[0057] Embodiment 2 is an embodiment of performing laser cladding on the piston rod of the hydraulic support cylinder based on resistance heating wire heating.

[0058] 1. This embodiment is laser cladding on the surface of the hydraulic support cylinder piston rod (hereinafter referred to as the piston rod), the diameter of the piston rod is 260mm, the length of the cladding area is 1900mm, and the material is 27SiMn.

[0059] 2. The ultra-high-speed laser cladding scheme of the piston rod in this embodiment adopts a 4Kw laser beam, and the spot where the laser beam converges at the position of the molten pool is a circular spot with a diameter of 3 mm. The angle between the laser beam and the inner ceramic tube is adjusted to 25°, the distance from the molten pool to the end face of the inner ceramic tube is 13mm.

[0060] 3. Choose an airborne disc-type powder feeder, the material is 304L stainless steel powder, the powder particle size is 45-150um, put the powder into the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com