Method for accurately controlling proportion of specific fatty acid in oil by adopting microcirculation technology

A technology for refining oils and fatty acids, which is applied in the field of using microcirculation technology to precisely control the proportion of specific fatty acids in oils and fats, which can solve the problems of inability to precisely control the content of specific fatty acids, inability to meet preparation requirements, and achieve the effect of extending the duration of the refining process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

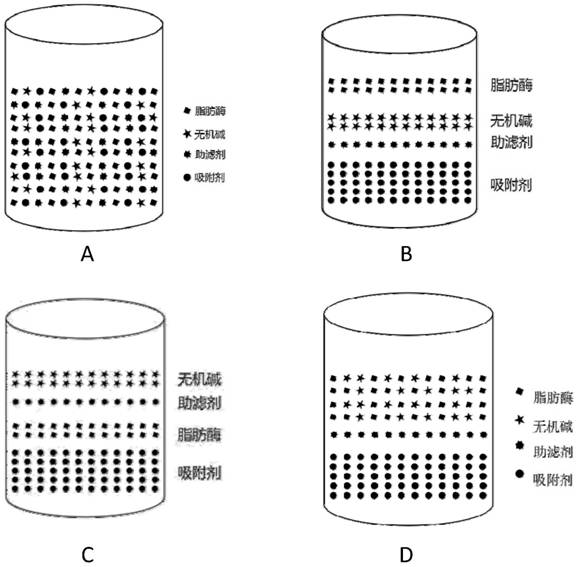

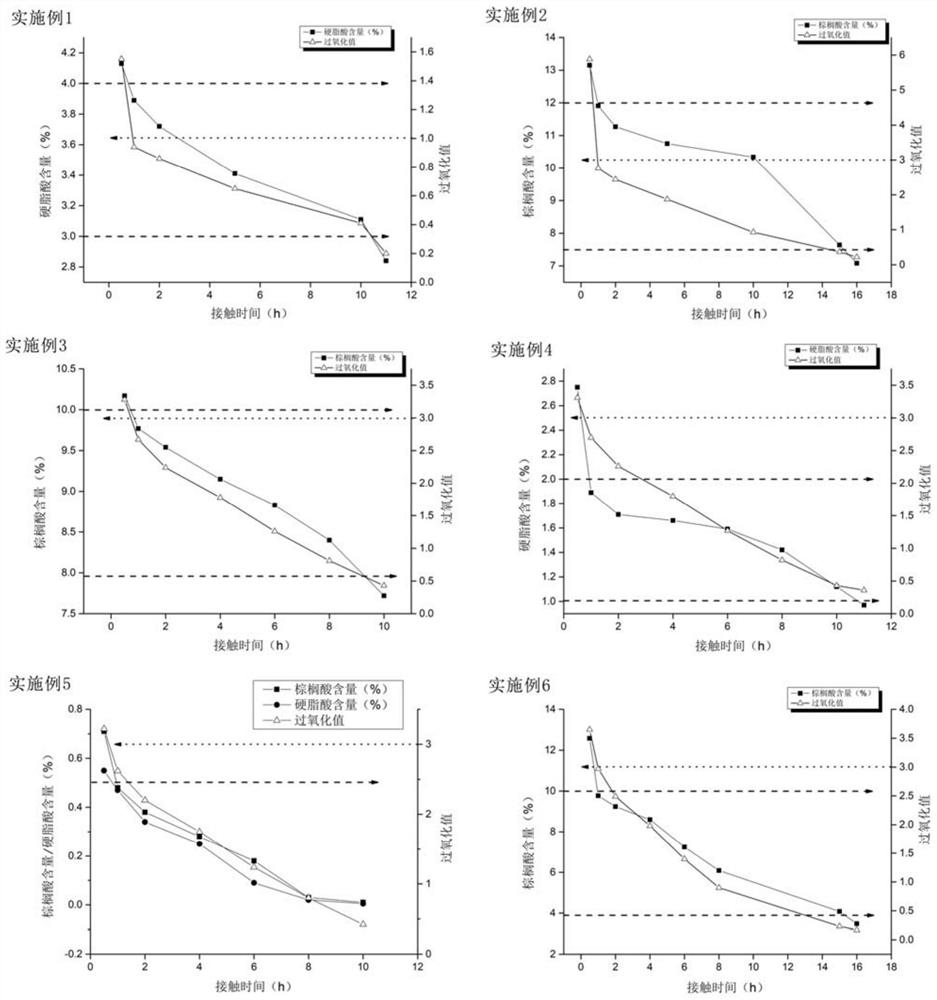

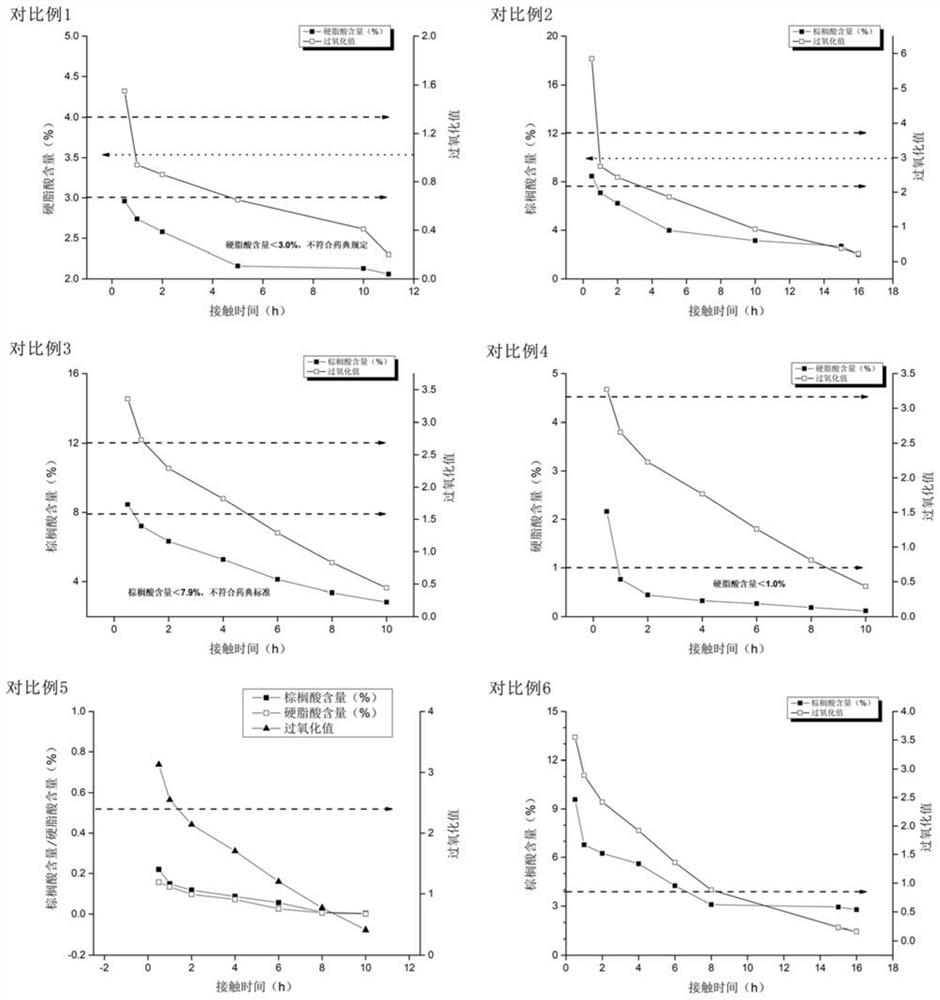

[0040] Weigh 5g of Sn-1, 3-position-specific lipase Lipase lipase, 10g of sodium hydroxide, 50g of diatomaceous earth, and 50g of silica gel, mix them uniformly physically, and add them to the chromatographic column, such as figure 1 -A shown. Take 1 kg of edible soybean oil, and carry out the operation of the above-mentioned mixed packing column chromatography, the column temperature is controlled at 45±2°C, the pressure is controlled at 0.2±0.02mPa, and the contact time is 4h. The acid value, methoxyaniline value, peroxide value and stearic acid content of soybean oil before and after refining were detected. The measurement results are shown in Table 1 (wherein, the acid value, peroxide value, and methoxyaniline value are measured and calculated according to the methods shown in the Pharmacopoeia).

[0041] Table 1 Example 1 Key index measurement results before and after soybean oil refining

[0042]

[0043]

Embodiment 2

[0045] Weigh 150 g of Sn-1, 3-position specific lipase RMIM lipase, 180 g of sodium hydroxide, 100 g of diatomaceous earth, and 100 g of silica gel, mix them uniformly physically, and add them to the chromatographic column, such as figure 1 -A shown. Take 2kg of virgin olive oil, and carry out the operation of the above-mentioned mixed packing column chromatography, the column temperature is controlled at 55±2°C, the pressure is controlled at 0.1±0.02mPa, the time for passing through the column is 12h, and the number of cycles is 1. Detect the acid value, methoxyaniline value, peroxide value and palmitic acid content of olive oil before and after refining. The measurement results are shown in Table 2 (wherein, the acid value, peroxide value, and methoxyaniline value are measured and calculated according to the methods shown in the Pharmacopoeia).

[0046] Table 2 Example 2 Determination results of key indicators before and after extra virgin olive oil refining

[0047]

Embodiment 3

[0049] Weigh 50g of Sn-1, 3-position-specific lipase 435 lipase, 100g of potassium hydroxide, 300g of bentonite, and 300g of clay, and add them to the chromatography column through physical mixing, such as figure 1 -A shown. Take 3 kg of edible sesame oil and pass it through a mixed packing chromatography column. The column temperature is controlled at 50±2°C, the pressure is controlled at 0.2±0.02mPa, and the time for passing the column is 8h. Detect the acid value, methoxyaniline value, peroxide value and palmitic acid content before and after refining. The measurement results are shown in Table 3 (wherein, the acid value, peroxide value, and methoxyaniline value are measured and calculated according to the methods shown in the Pharmacopoeia).

[0050] Table 3 Example 3 The results of key index determination before and after refining edible sesame oil

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com