Modified epoxy asphalt and preparation method thereof

A technology of epoxy asphalt and modification, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor compatibility of modified epoxy asphalt, achieve high compatibility, improve compatibility and modification , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

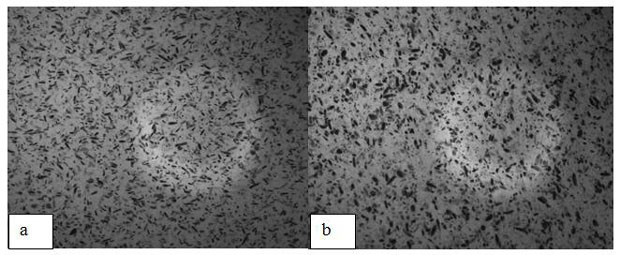

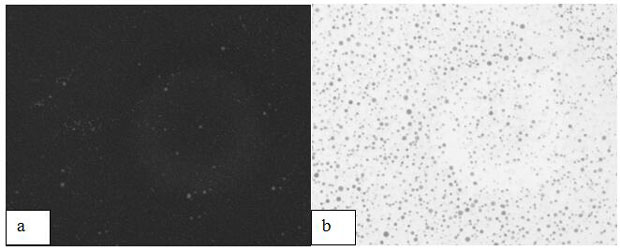

[0054] (1) 60 parts by weight of base asphalt I (25.4wt% saturated, 29.5wt% aromatic, 44.9wt% colloid, 0.2wt% asphaltenes) and 40 parts by weight base asphalt II (saturation 28.6wt%, aromatics accounted for 36.4wt%, colloids accounted for 19.2wt%, asphaltenes accounted for 15.8wt%) preheated to a fluid state and mixed, stirred at 140 ° C for 4 hours, the stirring speed was 300 r / min , to obtain mixed asphalt; then slowly add 0.2 parts by weight of polyphosphoric acid, continue heating to 160 ° C, adjust the stirring speed to 500 r / min, and stir for 6 hours to obtain modified blended asphalt a1.

[0055] (2) Pour 100 parts by weight of modified blended asphalt a1 heated to flow state into the autoclave, adjust the temperature in the autoclave to 110°C, keep stirring at a speed of 300 r / min, and continue stirring for 0.5h after the temperature is constant; 4 parts by weight of β-cyclodextrin were slowly added to the reactor within 1 hour, and the temperature was programmed to ri...

Embodiment 2

[0061] (1) 45 parts by weight of base pitch I (27.1 wt% saturated, 32.2 wt% aromatic, 40.1 wt% colloid, 0.6 wt% asphaltenes) and 55 parts by weight base pitch II (saturated 26.4wt%, aromatics accounted for 33.8wt%, colloids accounted for 17.8wt%, asphaltenes accounted for 22.0wt%) preheated to a fluid state and mixed, stirred at 150°C for 4 hours, the stirring speed was 300 r / min to obtain mixed asphalt; then slowly add 0.3 parts by weight of polyphosphoric acid, continue heating to 170°C, adjust the stirring speed to 500 r / min, and stir for 6 hours to obtain modified blended asphalt a2.

[0062] (2) Pour 100 parts by weight of modified blended asphalt a2 heated to flow state into the autoclave, adjust the temperature inside the autoclave to 120°C, keep stirring at a speed of 300 r / min, and continue stirring for 0.5h after the temperature is constant; 5 parts by weight of β-cyclodextrin were slowly added to the reactor within 1.5 hours, and the temperature was programmed to ri...

Embodiment 3

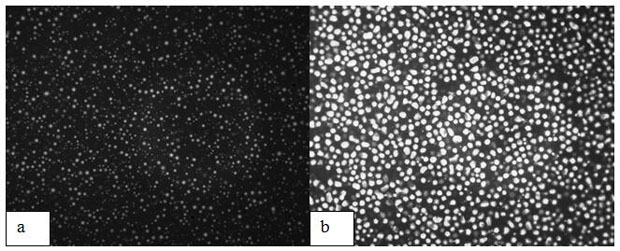

[0068] (1) Preheat 40 parts by weight of base asphalt I (same as in Example 2) and 60 parts by weight of base asphalt II (same as in Example 2) to a fluid state and mix them at 150°C for 4 hours at a stirring speed of 300 r / min to obtain mixed asphalt; then slowly add 0.2 parts by weight of polyphosphoric acid, continue heating to 170°C, adjust the stirring speed to 500 r / min, and stir for 6 hours to obtain modified blended asphalt a3.

[0069] (2) Pour 100 parts by weight of modified blended asphalt a3 heated to flow state into the autoclave, adjust the temperature inside the autoclave to 120°C, keep stirring at a speed of 300 r / min, and continue stirring for 1.5 hours after the temperature is constant; 5 parts by weight of β-cyclodextrin were slowly added to the reactor within 1.5 hours, and the temperature was programmed to rise to 135°C at a speed of 0.5°C / min. During the addition process, the stirring speed was maintained at 300 r / min, and the stirring was continued for 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com