A kind of organic carrier-free polysiloxane particle and preparation method thereof

A technology of polysiloxane and organic carrier, applied in the field of organic carrier-free polysiloxane particles and their preparation, can solve the problems of limited use and promotion, limited application of boric acid, etc., and achieves improved processing fluidity and improved surface finish. Smooth, easy granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

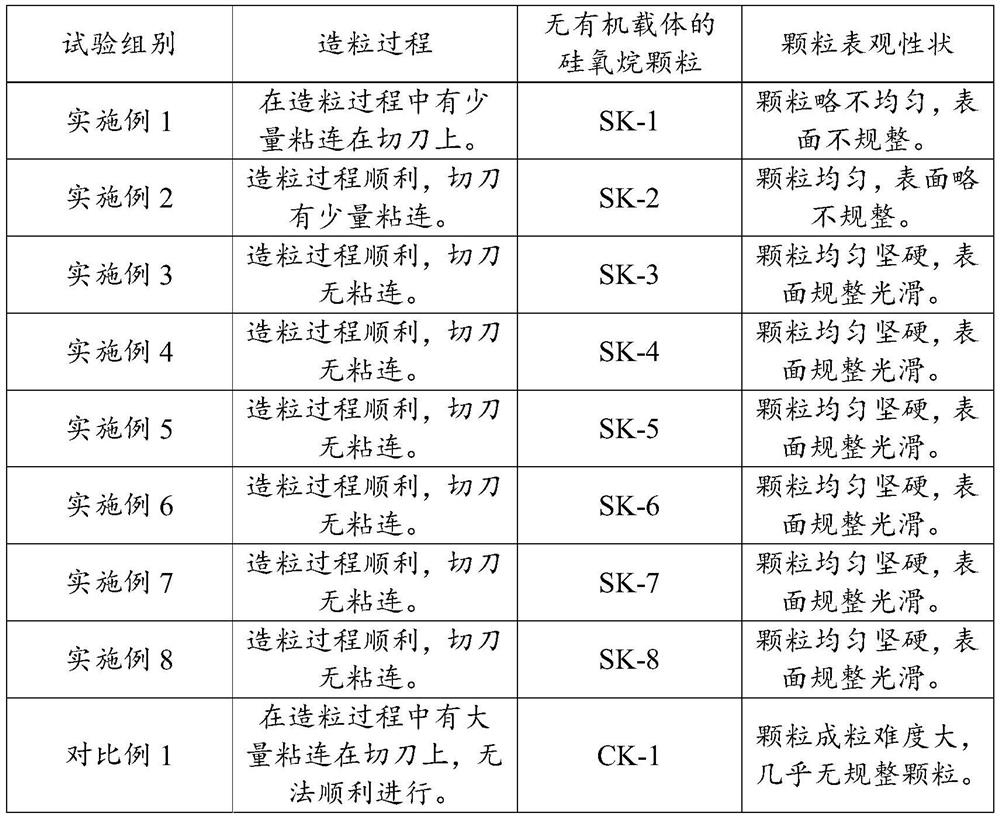

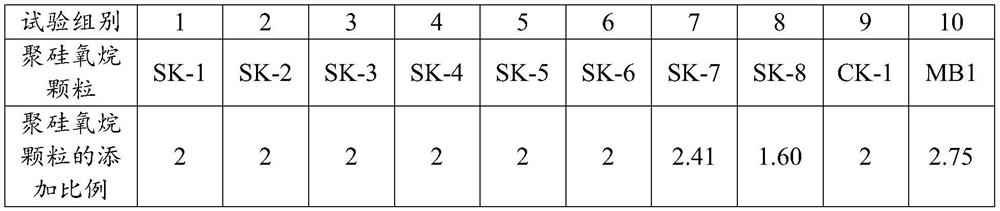

Examples

preparation example Construction

[0018] The invention provides a preparation method of organic carrier-free polysiloxane particles, which comprises the following steps: S1. Reaction and mixing of polysiloxane, silica, grafting agent and catalyst A in a kneader or an internal mixer 0.5 to 3 hours, a high-viscosity polysiloxane composition is prepared; the polysiloxane contains 0.02%-0.2% of vinyl groups; S2. The high-viscosity polysiloxane composition and filler prepared in step S1 are used Melt mixing and extrusion granulation to prepare organocarrier-free polysiloxane granules.

[0019] In the present invention, by melt-mixing reaction of vinyl group-containing polysiloxane, silica, grafting agent and catalyst A, silica with a large number of hydrogen bonds on the surface and vinyl group-containing polysiloxane can generate silicon hydrogen Addition reaction, so that the silica is grafted on the surface of polysiloxane, and at the same time, the polysiloxane itself undergoes a chain extension reaction, under...

Embodiment 1

[0038] A preparation method of organic carrier-free polysiloxane particles, comprising the steps of:

[0039] S1. Set the viscosity to 5×10 6 mPa·S, 100 parts of linear polysiloxane with vinyl content of 0.12%, specific surface area of 180m 2 10 parts of superfine silica by precipitation method per g, 0.005 part of hydrogen-containing siloxane containing 0.35% hydrogen and 1 part of Pt-containing catalyst A with a Pt content of 500 ppm, react and mix in an internal mixer at 150° C. for 2 hours to prepare The obtained high-viscosity polysiloxane composition is denoted as A;

[0040] S2. The specific surface area of the high-viscosity polysiloxane composition A prepared in step S1 and 50 parts of the surface-treated silane coupling agent is 180 m 2 / g of precipitated silica, added to the kneader and mixed at 150°C for 3 hours; then the mixed material was fed into a reciprocating single-screw extruder through a double cone and extruded at 150°C, and pelletized by air-cooled...

Embodiment 2

[0042] A preparation method of organic carrier-free polysiloxane particles, the difference from Example 1 is:

[0043] The white carbon black in step S1 is replaced with modified white carbon black A, and the preparation method of modified white carbon black A includes: the specific surface area is 180 m 2 100 parts of precipitation method ultrafine white carbon black and 3 parts of vinyltrimethoxysilane were kneaded in a kneader at 150°C.

[0044] The polysiloxane particles prepared in step S2 of this example are denoted as SK-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com