3D type soft heat preservation floor and manufacturing process thereof

A production process and soft technology, applied in the field of plate processing, can solve the problems of unglue and deformation impact resistance, single visual effect, high production cost, etc., achieve the effect of anti-glue deformation buffer capacity, reduce air pollution, and save processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

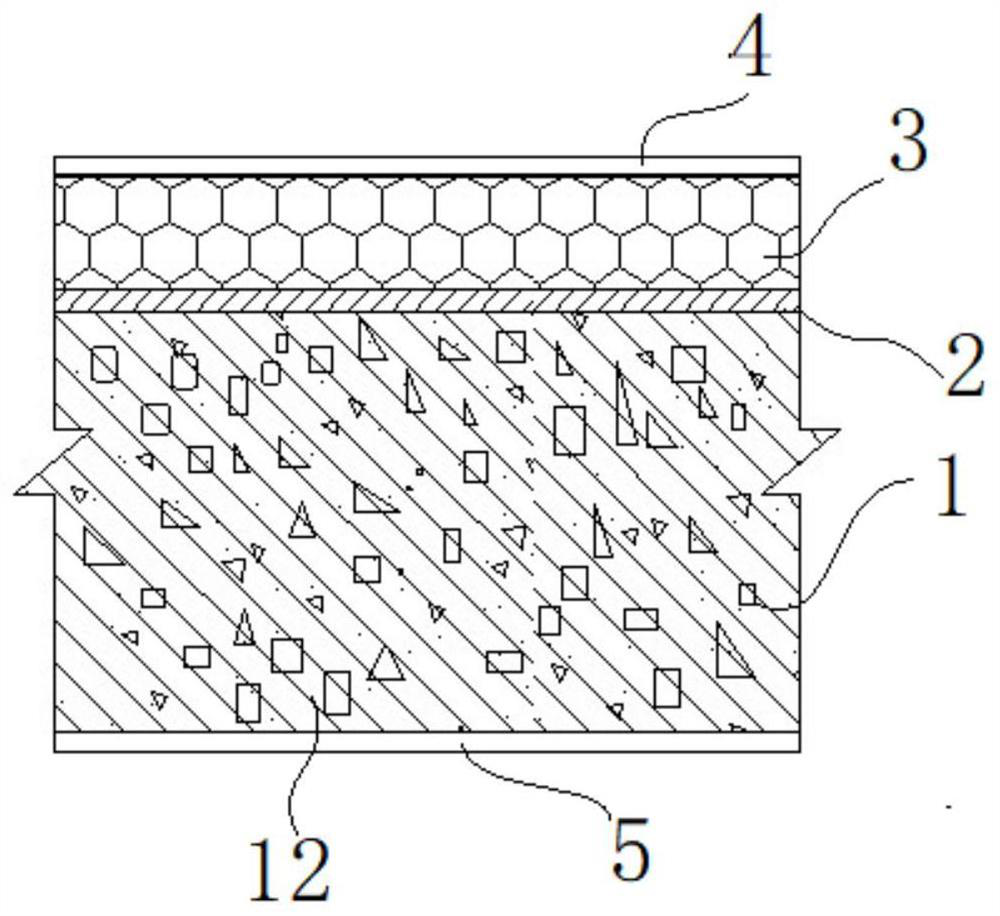

[0042] Such as figure 1 As shown, the 3D soft thermal insulation floor of this embodiment includes a balance layer 5, a soft substrate 1, a cloth fiber layer 2, a thermal insulation rock wool layer 3 and a 3D visual effect layer 4 that are laminated and distributed from the bottom to the top. The cloth fiber layer 2 is made of mixed yarn and aramid fiber; when stacking and distributing, the cloth fiber layer 2 can be dipped in glue to improve the horizontal friction between the soft substrate 1 and the thermal insulation rock wool layer 3, and at the same time make the two Or firmly bonded in the vertical direction.

[0043] In the 3D soft insulation floor of this embodiment, the soft substrate 1 may not use any wood components, and its components include calcium powder, green powder, polyvinyl chloride, recycled materials and resin powder, accounting for about 70%. Recycling refers to the leftover material in the board making process, which can be recycled; green powder is t...

Embodiment 2

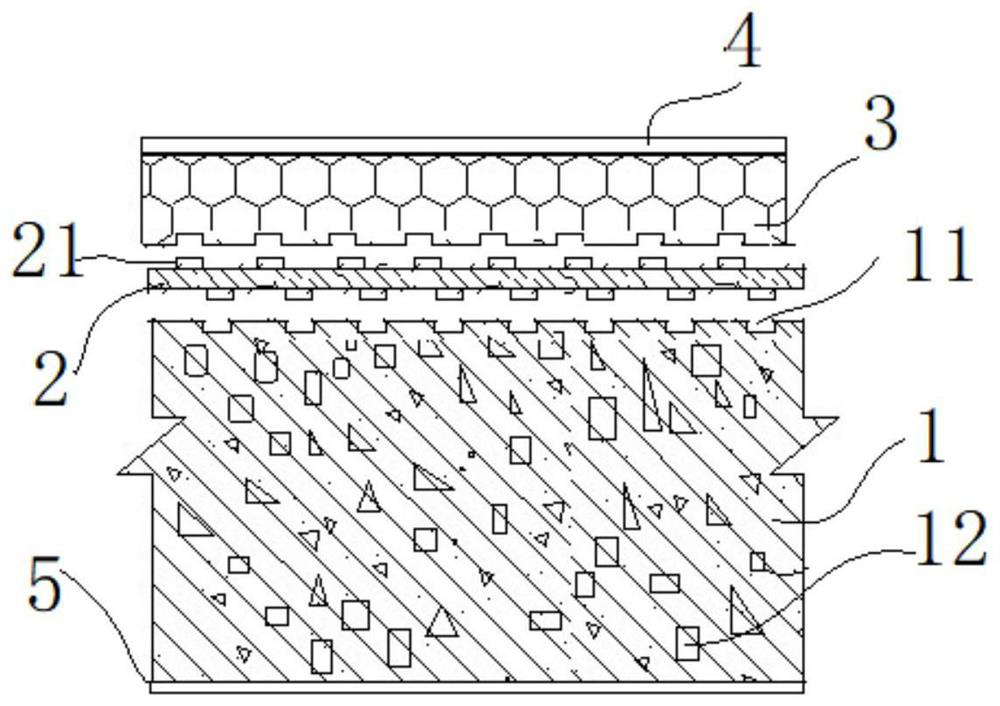

[0046] The 3D soft thermal insulation floor of this embodiment is further improved on the basis of Embodiment 1. The soft substrate 1 is a soft roll-formed glued board, that is, the base material of the soft substrate 1 is extruded and then rolled In this way, when superimposed with the cloth fiber layer 2, the cloth fiber layer 2 does not need to be impregnated, thereby saving the process and improving production efficiency; the insulation rock wool layer 3 is made of high-quality basalt , dolomite, etc. as the main raw materials, after high-temperature melting, use a four-axis centrifuge to centrifuge into fibers at a high speed, and spray a certain amount of binder, dust-proof oil, and water repellent at the same time, collect them by a cotton collector, and pass the pendulum method. , plus the three-dimensional method of laying cotton and then curing and cutting, the thermal insulation rock wool layer 3 prepared by this method can easily absorb the glue of the cloth fiber l...

Embodiment 3

[0056] The 3D soft thermal insulation floor and its manufacturing process of this embodiment are further improved on the basis of Embodiment 2. In step A, the straw segment 12 and the glue can be mixed first, and then the additives and other components can be mixed in order After mixing, in other components, on the basis of Examples 1 and 2, add phase-change polyethylene microcapsules with a weight ratio of about 10%; the straw segment 12 and the glue are mixed first, so that the glue can be mixed first Temporarily stored in the hollow structure of the straw 12, especially the wheat straw, the hollow volume is larger, and the glue solution can temporarily store more. In this way, the amount of glue solution exudation will be larger in the later roll forming. Phase-change polyethylene microcapsules are phase-change polyethylene microcapsules, which are prepared through the steps of preparing oil phase and water phase, shearing by homogenizer, heating and cooling in hydrothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com