Preparation method of buckwheat hull non-flavonoid substance

A buckwheat hull non-flavonoid and buckwheat hull technology is applied in medical preparations, drug combinations, and pharmaceutical formulations containing active ingredients, which can solve problems such as excessive production of ROS.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of buckwheat hull non-flavonoid components

[0040] 1. Sample processing

[0041] Select natural buckwheat hulls, remove impurities, dry, crush, and pass through a 0.25 mm (60 mesh) sieve; accurately weigh 1g of buckwheat hull powder, place it in a 50mL centrifuge tube, heat water to keep warm to extract water-soluble components, filter with suction, and make the filtrate to volume to 100mL to obtain a BHE solution, which was stored for future use.

[0042] 2. Extraction of non-flavonoid components from buckwheat hulls

[0043] 1. Pretreatment of macroporous resin

[0044] Soak D101 macroporous resin and AB-8 macroporous resin in 95% ethanol for 24 h to remove impurities. Ethanol was filtered off and washed with distilled water until odorless. Soak in 4% HCl and 4% NaOH solution for 24 hours in turn, wash with distilled water to pH 7.0 after each soaking, and finally soak in 95% ethanol, save for future use.

[0045] 2. Primary purification of...

Embodiment 2

[0049] Example 2 Separation and purification of non-flavonoid substances from buckwheat hulls

[0050] 1. Separation and purification

[0051] According to the principle of similar miscibility, using the different solubility of solutes in different organic solvents, the organic impurities mixed in the non-flavonoid components of buckwheat hulls are separated; the order of polarity of the main organic reagents is: water (maximum) > acetonitrile >methanol>ethanol>propanol>acetone>tetrahydrofuran>n-butanol>ethyl acetate>diethyl ether>isopropyl ether>dichloromethane>chloroform (chloroform)>bromoethane>benzene>carbon tetrachloride>n-hexane > Kerosene (minimum); In this experiment, chloroform, ethyl acetate, n-butanol and water, which are effective for most organic substances, were selected for three-phase extraction, and according to the polarity, chloroform, ethyl acetate, and n-butanol were used in sequence to achieve The effect of synergistic extraction.

[0052] Since there a...

Embodiment 3

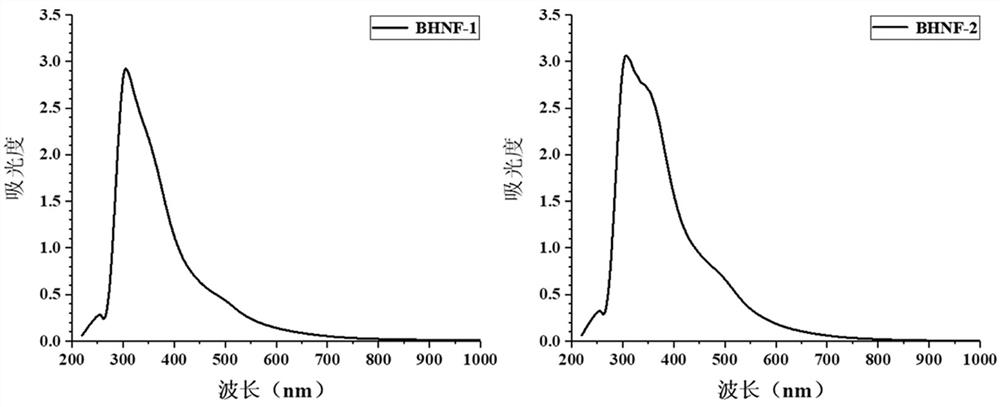

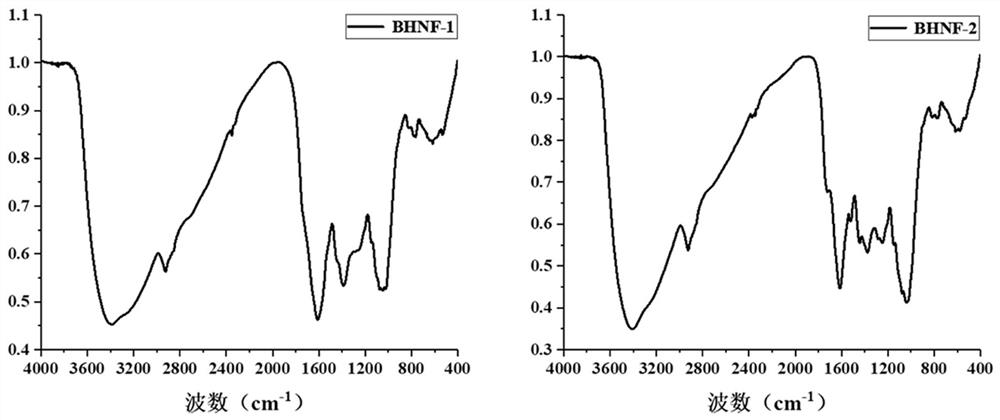

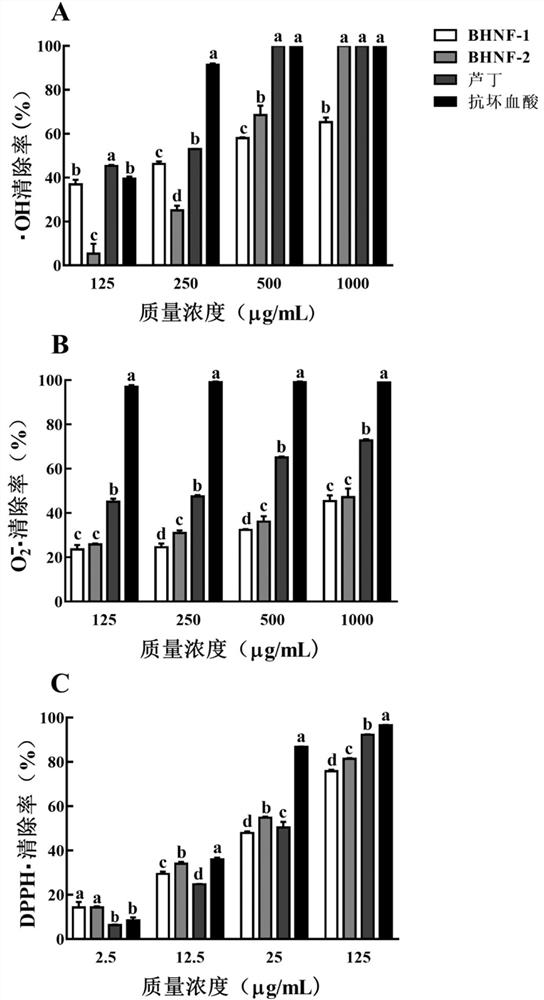

[0060] Example 3 Determination of non-flavonoid substances in buckwheat husk

[0061] 1. Color reaction

[0062] Using ferric chloride reaction, the BHNF-1 component and BHNF-2 component were prepared into 1 mg / mL sample solution, respectively, and the ferric chloride solution was added to react, and the color change of the solution was observed.

[0063] Using hydrochloric acid-magnesium powder reaction, the BHNF-1 component and BHNF-2 component were prepared into 1 mg / mL sample solution, and a few drops of concentrated hydrochloric acid and a small amount of magnesium powder were added to react, and the color change of the solution was observed.

[0064] Results: In the ferric chloride color reaction, the solutions of BHNF-1 and BHNF-2 components became darker and brownish black, indicating that the non-flavonoid components of buckwheat hulls may contain phenolic or tannin components. However, in the hydrochloric acid-magnesium powder test, the BHNF-1 and BHNF-2 components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com