Functional organic silicon resin for protein adsorption and light-operated desorption and preparation method of functional organic silicon resin

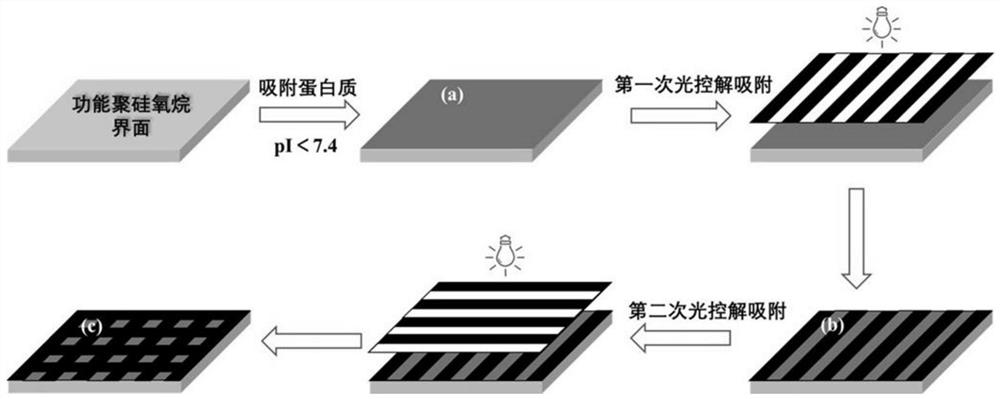

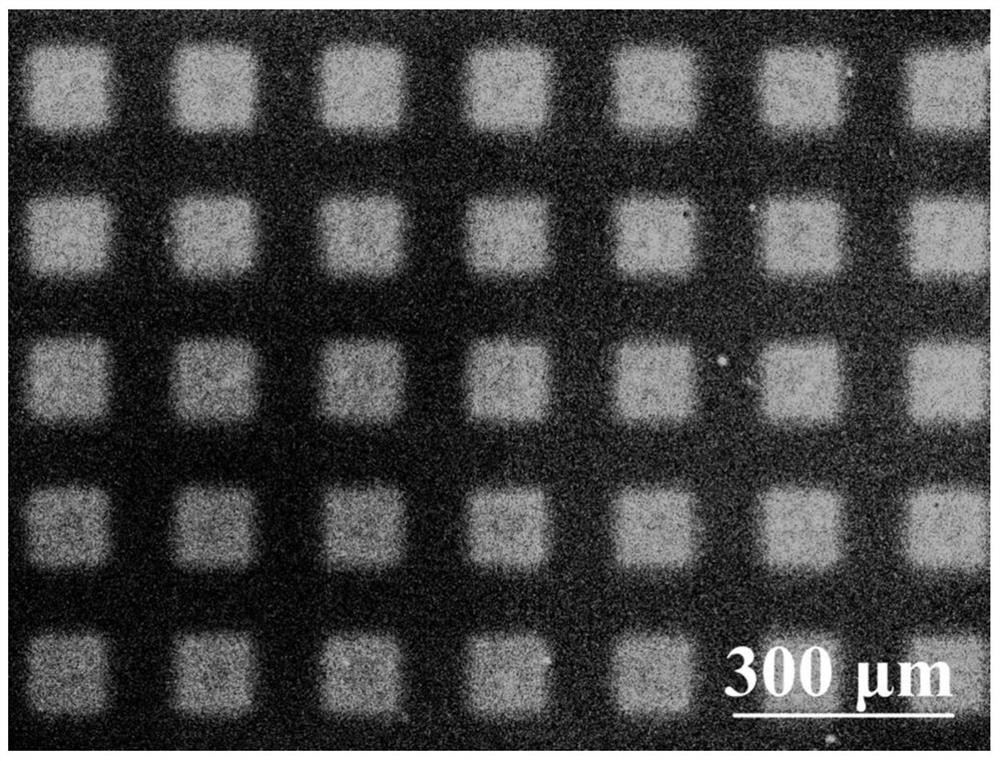

An organosilicon and protein technology, applied in functional polymer materials and biological fields, to achieve the effect of good light responsiveness and light control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

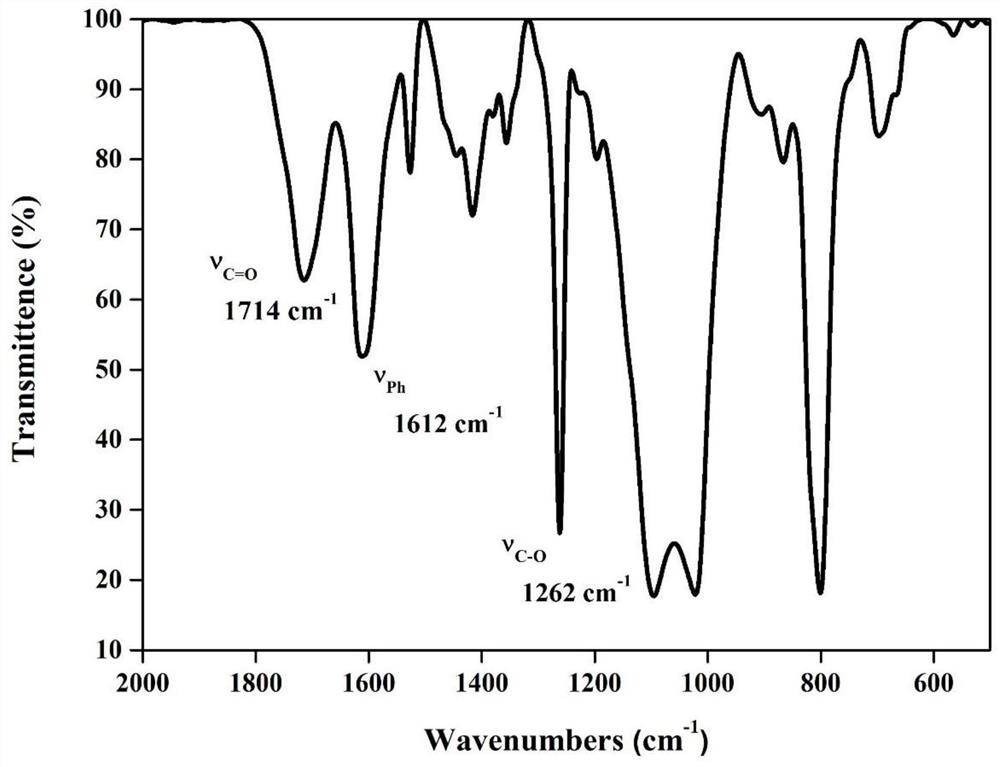

Embodiment 1

[0088] A method for preparing a functional silicone resin for adsorption and light-controlled desorption of protein molecules, comprising the following steps:

[0089] (1) 7-N,N-diethylamino-4-methylcoumarin (4.63g, 20mmol) was dissolved in 1,4-dioxane (120mL), and selenium dioxide was added to the above solution (3.33g, 30mmol). The reaction mixture was stirred and heated to reflux for 24h. After filtration, it was concentrated under reduced pressure to obtain a brown oil, which was dissolved in methanol (130 mL), and sodium borohydride (380 mg, 10 mmol) was added. The solution was stirred at room temperature for 4 h. The resulting suspension was carefully hydrolyzed with 1M HCl solution (20 mL), and after dilution with water, the resulting solution was extracted three times with dichloromethane (20 mL). The organic phase was washed three times with water (30 mL), saturated sodium bicarbonate solution (30 mL) and water (30 mL), respectively, and dried over anhydrous magnes...

Embodiment 2

[0099] A method for preparing a functional silicone resin for adsorption and light-controlled desorption of protein molecules, comprising the following steps:

[0100] (1) 7-N,N-diethylamino-4-methylcoumarin (4.63g, 20mmol) was dissolved in 120mL1,4-dioxane, and selenium dioxide (2.22g ,20mmol). The reaction mixture was stirred and heated to reflux for 72h. After filtration and concentration under reduced pressure, the obtained brown oil was dissolved in methanol (130 mL), and sodium borohydride (380 mg, 10 mmol) was added. The solution was stirred at room temperature for 4 h. The resulting suspension was carefully hydrolyzed with 1M HCl solution (20 mL), and after dilution with water, the resulting solution was extracted three times with dichloromethane (20 mL). The organic phase was washed three times with water (30 mL), saturated sodium bicarbonate solution (30 mL) and water (30 mL), respectively, and dried over anhydrous magnesium sulfate. After suction filtration, sol...

Embodiment 3

[0107] A method for preparing a functional silicone resin for adsorption and light-controlled desorption of protein molecules, comprising the following steps:

[0108] (1) 7-N,N-diethylamino-4-methylcoumarin (4.63g, 20mmol) was dissolved in 120mL1,4-dioxane, and selenium dioxide (3.33g ,30mmol). The reaction mixture was heated to reflux under stirring for 48h. After filtration and concentration under reduced pressure, the obtained brown oil was dissolved in methanol (130 mL), and sodium borohydride (380 mg, 10 mmol) was added. The solution was stirred at room temperature for 4 h. The resulting suspension was carefully hydrolyzed with 1M HCl solution (20 mL), and after dilution with water, the resulting solution was extracted three times with dichloromethane (20 mL). The organic phase was washed three times with water (30 mL), saturated sodium bicarbonate solution (30 mL) and water (30 mL), respectively, and dried over anhydrous magnesium sulfate. After suction filtration, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com