Manufacturing method of tillite teapot

A manufacturing method, Bing Ge rock technology, applied in the direction of manufacturing tools, crafts for producing decorative surface effects, decorative art, etc., can solve the problems of low efficiency, heavy manual carving labor, and the inability to realize quantitative production, etc., to achieve the taste Soft and sweet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

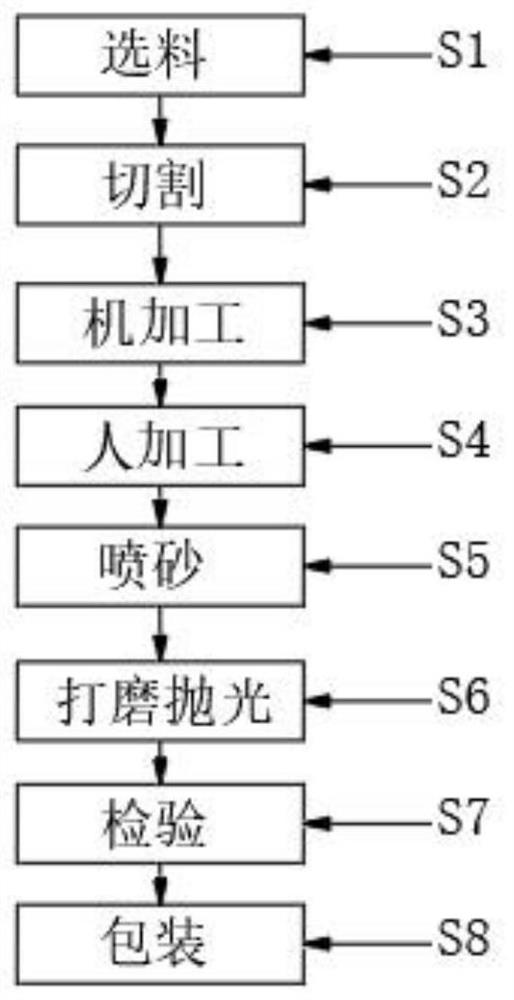

[0038] A method for manufacturing an ice teapot, comprising the following steps:

[0039]S1. Material selection: Determine the size of the teapot. According to the size of the teapot, choose 10 parts of ice rock raw materials that are 1.5 times the size of the teapot. The shape of the raw material is close to a rectangle without obvious deformities and protrusions. The pattern of the raw material is evenly distributed and the layering is richer;

[0040] S2. Cutting: simply clean the selected raw materials, remove the obviously loose parts on the surface, select a high-speed cutting sawing machine, fix the raw materials on the cutting sawing machine, and cut 8cm rough blanks whose length, width and height are greater than the length, width and height of the teapot , the saw blade should be made of cemented carbide or diamond saw blade, and the cutting speed should be 3000r / min;

[0041] S3. Machining: Fix the blank on the surface of the milling machine. The milling machine sel...

Embodiment 2

[0049] A method for manufacturing an ice teapot, comprising the following steps:

[0050] S1. Material selection: Determine the size of the teapot. According to the size of the teapot, choose 10 parts of ice rock raw materials that are twice the size of the teapot. The shape of the raw material is close to a rectangle without obvious deformities and protrusions. The pattern of the raw material is evenly distributed and the layering is richer;

[0051] S2. Cutting: simply clean the selected raw materials, remove the obviously loose parts on the surface, select a high-speed cutting saw machine, fix the raw materials on the cutting saw machine, and cut a 10cm rough blank whose length, width and height are greater than the length, width and height of the teapot , the saw blade should be made of carbide or diamond saw blade, and the cutting speed should be 5000r / min;

[0052] S3. Machining: Fix the blank on the surface of the milling machine. The milling machine selects a three-dim...

Embodiment 3

[0060] A method for manufacturing an ice teapot, comprising the following steps:

[0061] S1. Material selection: Determine the size of the teapot. According to the size of the teapot, choose 10 parts of ice rock raw materials that are 1.2 times the size of the teapot. The shape of the raw material is close to a rectangle without obvious deformities and protrusions. The pattern of the raw material is evenly distributed and the layering is richer;

[0062] S2. Cutting: simply clean the selected raw materials, remove the obviously loose parts on the surface, select a high-speed cutting sawing machine, fix the raw materials on the cutting sawing machine, and cut a 5cm rough blank whose length, width and height are greater than the length, width and height of the teapot , the saw blade should be made of carbide or diamond saw blade, and the cutting speed should be 3000r / minr / min;

[0063] S3. Machining: Fix the blank on the surface of the milling machine. The milling machine selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com