Self-adhesive dimming film

A technology of dimming film and photoinitiator, applied in the field of dimming film, can solve the problems of limiting the application scope and market performance of dimming film, and achieve the effect of convenient and rapid bonding, stable properties and good retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

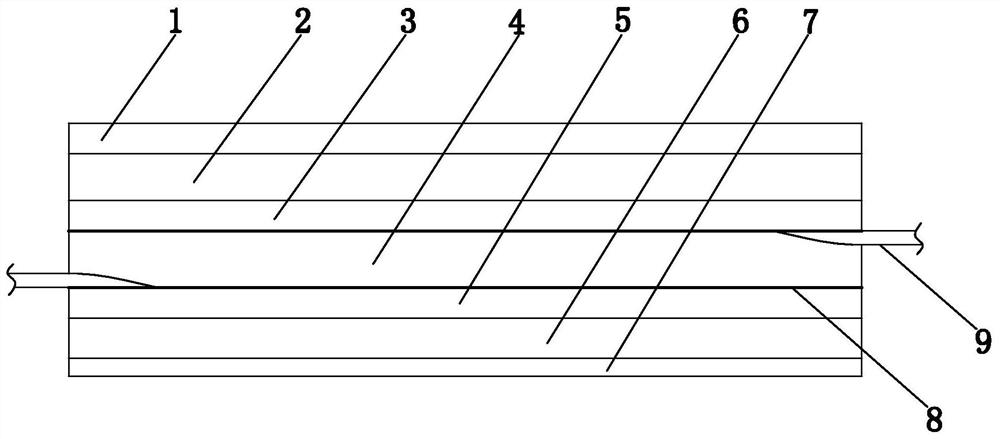

Embodiment 1

[0043] A thickness of 0.05mm, a transparency of 95%, an elongation of 1000%, and a PE film with a tensile strength of 45MPa are used as the outer protective layer 1, with 35 parts by mass of methacrylic resin, 45 parts of acrylic acid, 3 parts of the first photoinitiator and 0.1 part of the first auxiliary agent are used as raw materials to prepare the first adhesive layer 2 with a thickness of 0.10mm, and a PET with a thickness of 0.05mm, a light transmittance of 93%, and a shrinkage rate of 1% is used. The film is plated with an ITO metal conductive layer 8 by a magnetron sputtering process as the first conductive film layer 3 and the second conductive film, with 30 parts of oligomers, 10 parts of diluted monomers, and 50 parts of liquid crystal monomers in parts by mass. 0.08 part, 0.08 part of glass beads, 4 parts of the second photoinitiator and 0.2 part of the second auxiliary agent are raw materials to prepare a polymer dispersed liquid crystal layer 4 with a thickness o...

Embodiment 2

[0045] A thickness of 0.06mm, a transparency of 95%, an elongation of 900%, and a PE film of 36MPa in tensile strength are used as the outer protective layer 1, with 38 parts by mass of methacrylic resin, 48 parts of acrylic acid, 6 parts of the first photoinitiator and 0.5 part of the first auxiliary agent are used as raw materials to prepare the first adhesive layer 2 with a thickness of 0.12 mm, and a PET with a thickness of 0.06 mm, a light transmittance of 93%, and a shrinkage rate of 0.88% is used. The film is plated with an ITO metal conductive layer 8 as the first conductive film layer 3 and the second conductive film through a magnetron sputtering process, with 40 parts of oligomers, 12 parts of diluted monomers, and 48 parts of liquid crystal monomers in parts by mass. 5 parts, 0.5 parts of glass microspheres, 5 parts of the second photoinitiator and 0.4 parts of the second auxiliary agent are raw materials to prepare a polymer dispersed liquid crystal layer 4 with a ...

Embodiment 3

[0047] A thickness of 0.04mm, a transparency of 95%, an elongation of 950%, and a PE film of 39MPa in tensile strength are used as the outer protective layer 1, with 42 parts by mass of methacrylic resin, 52 parts of acrylic acid, 3 parts of the first photoinitiator and 0.7 parts of the first auxiliary agent are used as raw materials to prepare the first adhesive layer 2 with a thickness of 0.11mm, and a PET with a thickness of 0.04mm, a light transmittance of 94%, and a shrinkage rate of 0.72% is used. The film is plated with an ITO metal conductive layer 8 by a magnetron sputtering process as the first conductive film layer 3 and the second conductive film, with 36 parts of oligomers, 9 parts of diluted monomers, and 58 parts of liquid crystal monomers in parts by mass. 1.5 parts, 1.5 parts of glass microspheres, 6 parts of the second photoinitiator and 0.1 parts of the second auxiliary agent are raw materials to prepare a polymer dispersed liquid crystal layer 4 with a thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com