Flexible micro-chromatographic column with thin metal inner lining and preparation method thereof

A metal lining and chromatographic column technology, applied in the field of gas chromatography, can solve the problems of decreased separation performance, large temperature difference of the chromatographic column, unsynchronized elution process, etc., to eliminate the broadening of chromatographic peaks, and to emphasize the controllability and separation effect. , the effect of improving the uniformity of the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Structural design

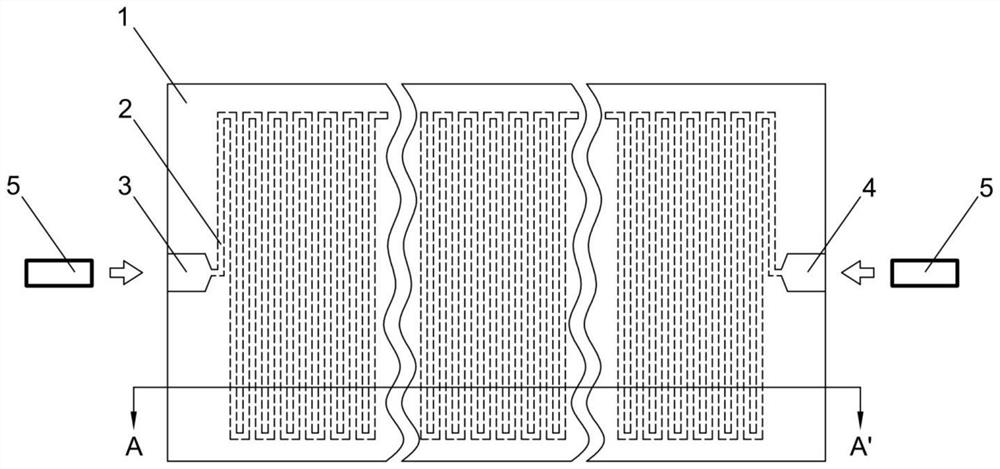

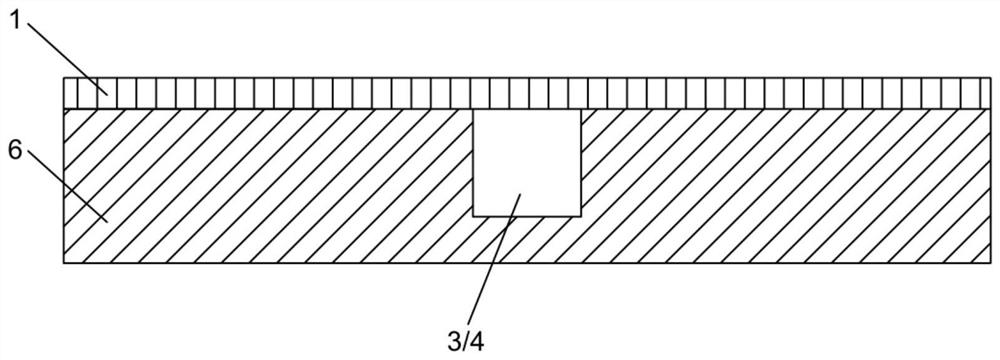

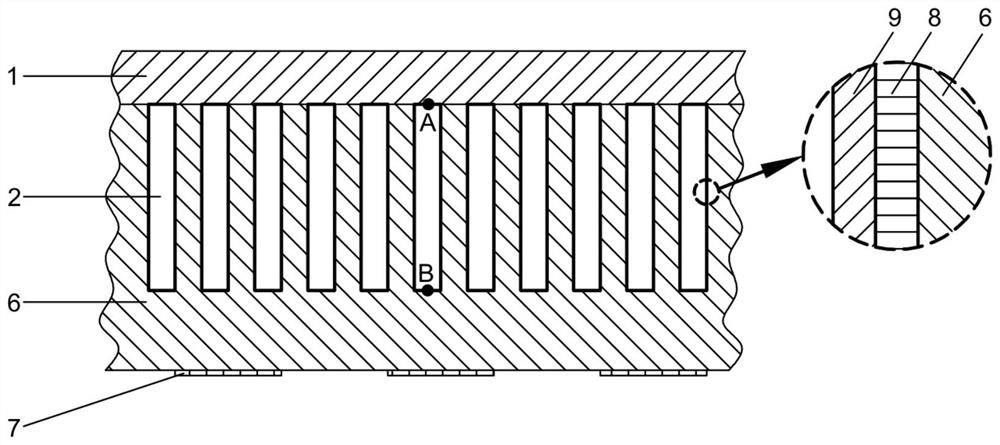

[0034] In this embodiment, the flexible micro-chromatographic column with a thin metal inner lining of the present invention is made of polydimethylsiloxane (PDMS), and the cross-sectional structure of this chromatographic column is shown in Figure 1 (c), including A thick PDMS flexible top cover 1 and a 500um thick PDMS flexible substrate 6, the chromatographic microchannel 2 encapsulated between the flexible substrate 6 flexible top cover 1, and a thin film heater made of a platinum film on the lower surface of the micro chromatographic column 7, and a copper thin film metal lining 8 with a thickness of about 1 μm deposited on the inner wall of the chromatographic microchannel 2 and a SE-54 stationary phase thin film 9 coated on the metal lining copper film 8 . The cross-section of the chromatographic microchannel 2 is rectangular, and the depth is about 350um. The projection of the microchannel on the upper surface of the flexible substrate ...

Embodiment 2

[0058] In this embodiment, polyimide (PI) is used as the base material of the flexible chromatographic column, and PDMS is still used as the top cover material. The device structure is exactly the same as that of Embodiment 1.

[0059] 1. Device processing

[0060] (1) MEMS processing of micro-chromatographic channels: Oxygen plasma deep groove etching technology was used to etch the channels of micro-chromatographic columns and the interfaces at both ends on the PI film with a thickness of 500 μm, and the etching depth was 350 μm.

[0061] (2) Channel sealing: select a 100 μm thick PDMS film, after cleaning, use oxygen plasma for surface treatment for 1 min, and then immediately attach it to the front of the above-mentioned PI substrate with a chromatographic channel structure, at 70 ° C Treat for 15min.

[0062] (3) Heater preparation: same as embodiment 1.

[0063] (4) Copper thin film coating on the inner cavity of the chromatographic channel: same as in Example 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com