Crude lead refining process for lead-acid battery recovery

A crude lead refining and lead-acid battery technology, which is applied in the field of crude lead refining and crude lead refining process for lead-acid battery recycling, can solve the problems of environmental pollution, low production cost, and less loss of precious metals, and achieve less loss of precious metals and higher production efficiency. The effect of low cost and high labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] see Figure 1-5 As shown, the present embodiment is a crude lead refining process for recycling lead-acid batteries, and the crude lead refining process comprises the following steps:

[0040] Step S1, configuration of electrolyte:

[0041] Stir and dissolve at room temperature to obtain a mixed solution, then add lead oxide powder and additives to the mixed solution, stir and dissolve at a temperature of 80°C and a stirring speed of 800r / min for 5 hours, then filter, and the obtained filtrate is the electrolytic solution. liquid;

[0042] Step S2, preparation of electrodes:

[0043] Crude lead is subjected to pyro-refining through a refining device, and the pyro-refined crude lead and electrodeposited refined lead are respectively cast into a crude lead anode and an electrodeposited lead cathode in a molten state;

[0044] Step S3, electrolysis:

[0045] The prepared electrolyte is added to the electrolytic cell, and the rough lead anode and the electrodeposited le...

Embodiment 2

[0053] see Figure 1-5 As shown, the present embodiment is a crude lead refining process for recycling lead-acid batteries, and the crude lead refining process comprises the following steps:

[0054] Step S1, configuration of electrolyte:

[0055] Stir and dissolve at room temperature to obtain a mixed solution, then add lead oxide powder and additives to the mixed solution, stir and dissolve at a temperature of 100°C and a stirring speed of 1000r / min for 7 hours, then filter, and the resulting filtrate is electrolytic liquid;

[0056] Step S2, preparation of electrodes:

[0057] Crude lead is subjected to pyro-refining through a refining device, and the pyro-refined crude lead and electrodeposited refined lead are respectively cast into a crude lead anode and an electrodeposited lead cathode in a molten state;

[0058] Step S3, electrolysis:

[0059] The prepared electrolyte is added to the electrolytic cell, and the rough lead anode and the electrodeposited lead cathode ...

Embodiment 3

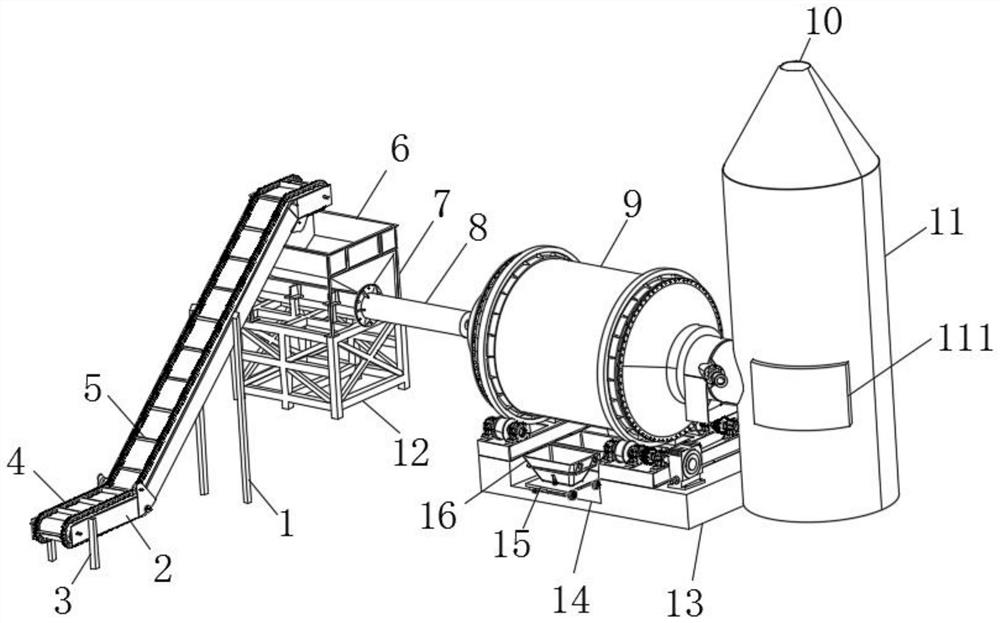

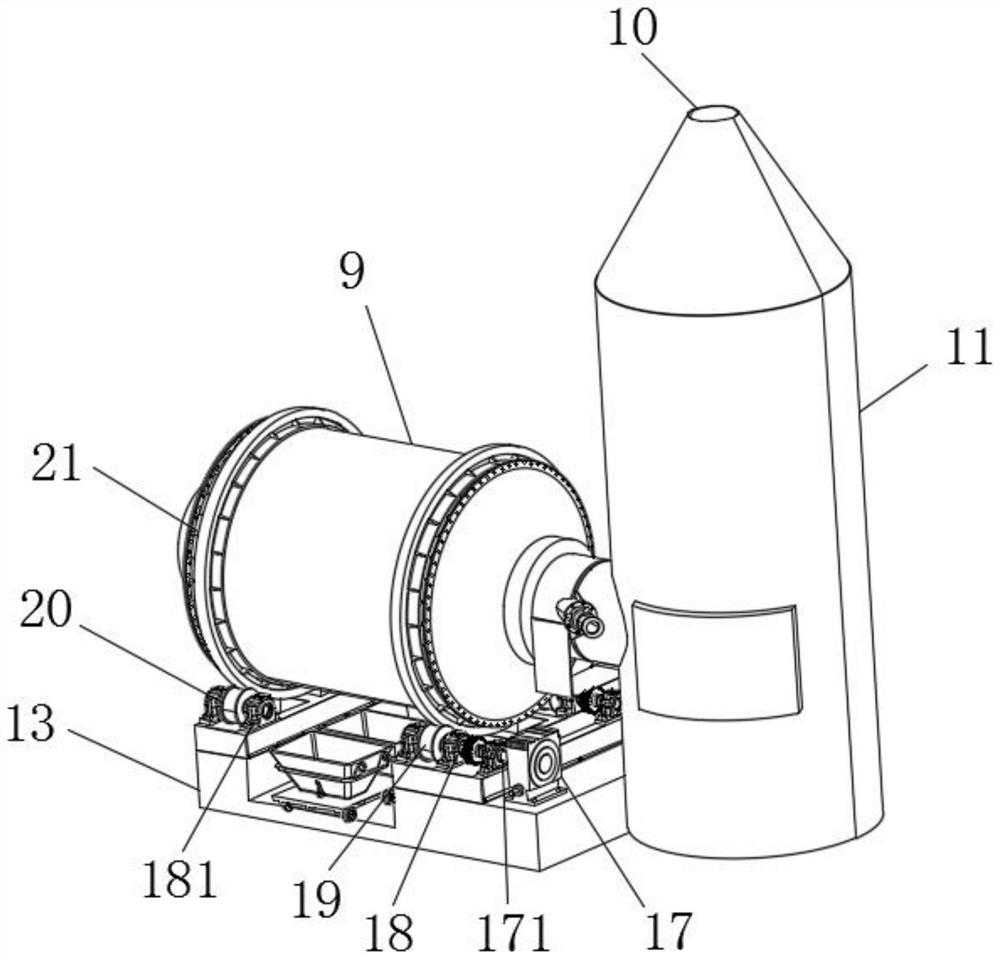

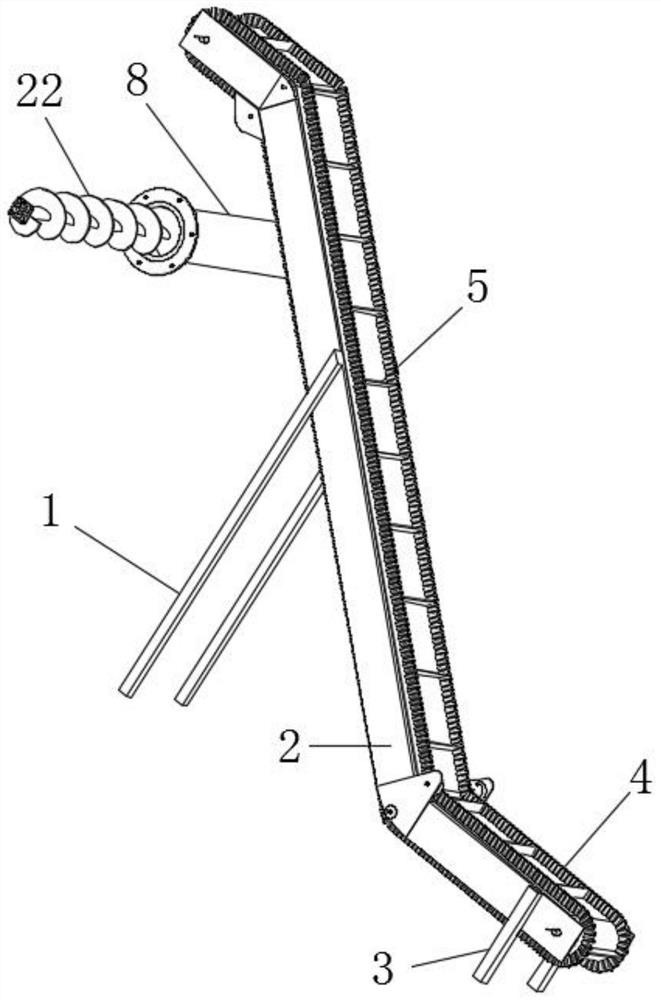

[0065] see Figure 1~5 As shown, the refining device in this embodiment includes a hoist 2, a conveying auger 8, a mixing drum 9 and a melting furnace 11. A placement rack 12 is placed on the lower side of the hoist 2, and one side of the placement rack 12 is placed There is a base 13, a mixing cylinder 9 is installed on the upper side of the base 13, a melting furnace 11 is installed on one side of the mixing cylinder 9, and an air outlet 10 is provided on the upper side of the melting furnace 11;

[0066] Wherein, the second support legs 3 are symmetrically installed on both sides of the hoist 2, the conveyor chain plate 4 is installed on the hoist 2, the material blocking plate 5 is installed on the conveyor chain plate 4, and the hoist 2 The first supporting leg 1 is installed on both sides of the side and close to the position of the placement frame 12, the upper side of the placement frame 12 is equipped with a conveying auger 8, and the upper side of the conveying auger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com