Low-sintering anti-ferroelectric ceramic material for high-energy-storage-density capacitors and preparation method thereof

A technology with high energy storage density and ceramic materials, which is applied in the field of functional ceramics, can solve the problems that cannot satisfy the preparation process of multilayer ceramic capacitors, and achieve excellent charge and discharge characteristics, lower sintering temperature, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

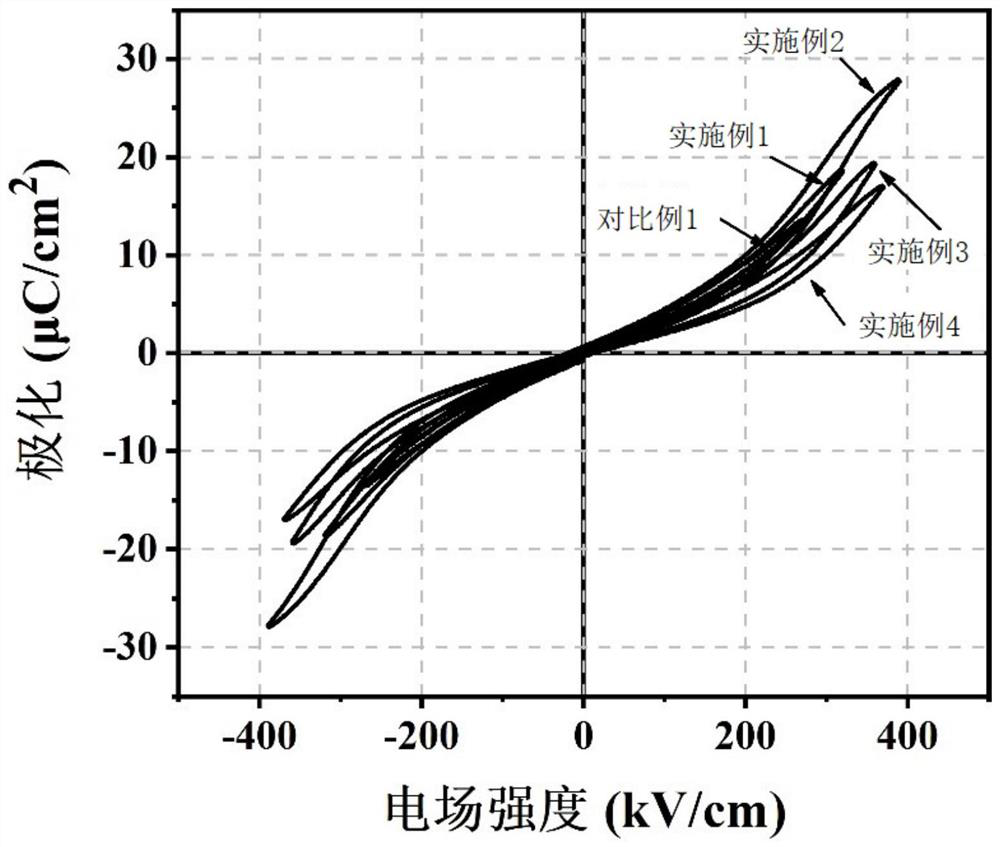

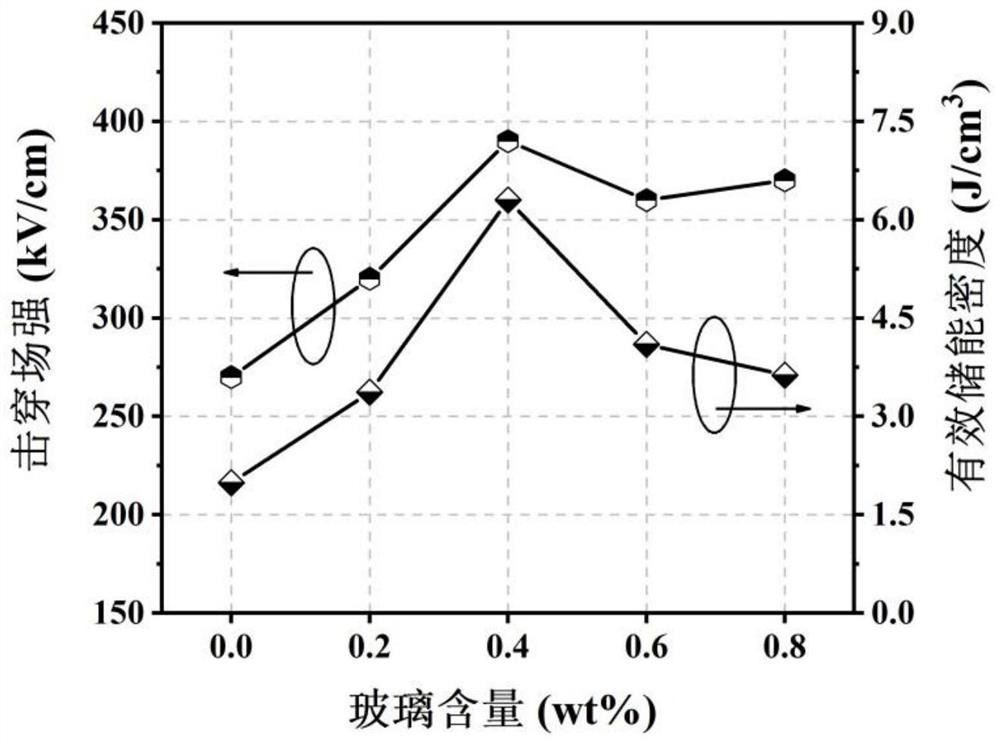

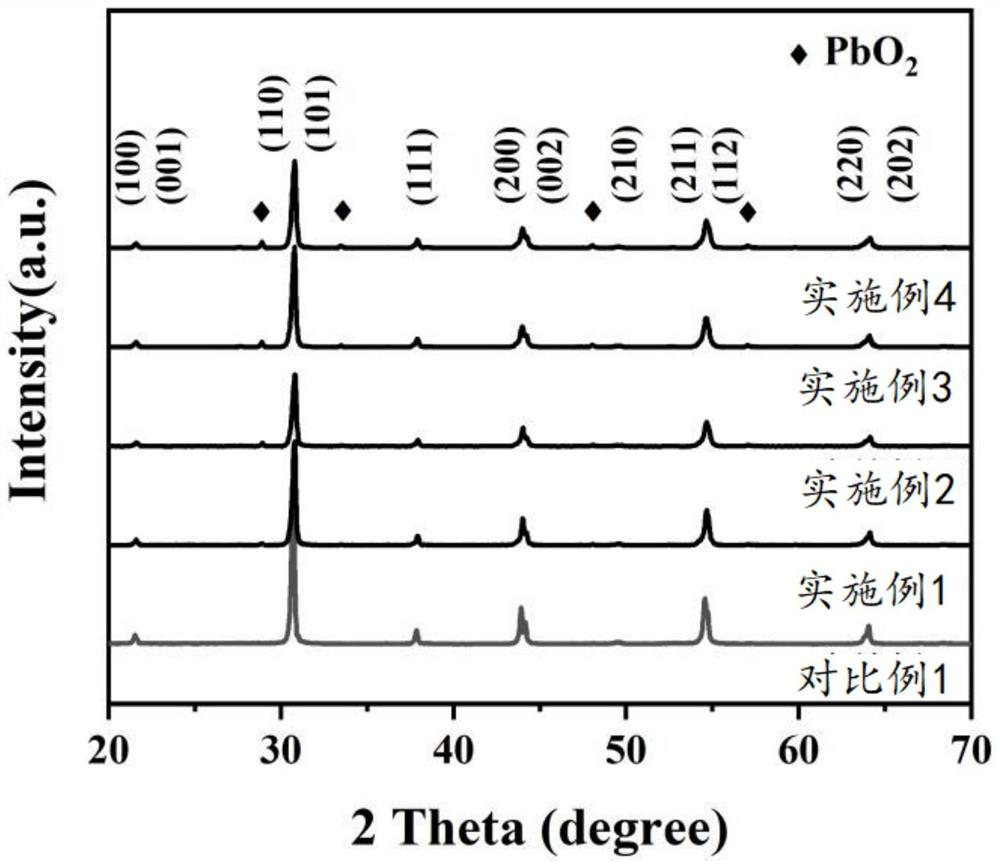

[0038] The chemical composition of antiferroelectric ceramics in the present embodiment is (Pb 0.91 Ba 0.015 La 0.05 )(Zr 0.6 sn 0.4 )O 3 +0.2wt%BaO-B 2 o 3 -Al 2 o 3 -SiO 2 , including the following steps:

[0039] (1) Select Pb with a purity greater than 99% 3 o 4 、BaCO 3 , La 2 o 3 , ZrO 2 , SnO 2 As a raw material for antiferroelectric ceramic phase;

[0040] (2) weigh according to the stoichiometric ratio, add ball milling medium and carry out ball milling, discharging, drying;

[0041] (3) Calcining the dried powder in a muffle furnace at 800-900°C for 2-3 hours;

[0042] (4) Add 0.2wt% barium-boron-aluminosilicate glass powder to the calcined powder, perform secondary ball milling, discharge, dry, granulate, sieve, and press under a pressure of 4 to 8 MPa into ceramic discs;

[0043] (5) debinding the obtained ceramic body in a muffle furnace;

[0044](6) The ceramic body after debinding is sintered at 1050-1200°C, the heating rate is controlled at ...

Embodiment 2

[0047] The chemical composition of antiferroelectric ceramics in the present embodiment is (Pb 0.91 Ba 0.015 La 0.05 )(Zr 0.6 sn 0.4 )O 3 +0.4wt% BaO-B 2 o 3 -Al 2 o 3 -SiO 2 , including the following steps:

[0048] (1) Select Pb with a purity greater than 99% 3 o 4 、BaCO 3 、La 2 o 3 , ZrO 2 , SnO 2 As a raw material for antiferroelectric ceramic phase;

[0049] (2) weigh according to the stoichiometric ratio, add ball milling medium and carry out ball milling, discharging, drying;

[0050] (3) Calcining the dried powder in a muffle furnace at 800-900°C for 2-3 hours;

[0051] (4) Add 0.4% barium borosilicate glass powder by mass to the calcined powder, perform secondary ball milling, discharge, dry, granulate, sieve, and press under a pressure of 4 to 8 MPa to form Ceramic disc;

[0052] (5) debinding the obtained ceramic body in a muffle furnace;

[0053] (6) The ceramic body after debinding is sintered at 1050-1200°C, the heating rate is controlled at ...

Embodiment 3

[0057] The chemical composition of antiferroelectric ceramics in the present embodiment is (Pb 0.91 Ba 0.015 La 0.05 )(Zr 0.6 sn 0.4 )O 3 +0.6wt% BaO-B 2 o 3 -Al 2 o 3 -SiO 2 , including the following steps:

[0058] (1) Select Pb with a purity greater than 99% 3 o 4 、BaCO 3 、La 2 o 3 , ZrO 2 , SnO 2 As a raw material for antiferroelectric ceramic phase;

[0059] (2) weigh according to the stoichiometric ratio, add ball milling medium and carry out ball milling, discharging, drying;

[0060] (3) Calcining the dried powder in a muffle furnace at 800-900°C for 2-3 hours;

[0061] (4) Add barium borosilicate glass powder of 0.2% by mass to the calcined powder, carry out secondary ball milling, discharge, dry, granulate, sieve, and press under a pressure of 4 to 8 MPa to form Ceramic disc;

[0062] (5) debinding the obtained ceramic body in a muffle furnace;

[0063] (6) The ceramic body after debinding is sintered at 1050-1200°C, the heating rate is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com