Pretreatment method of liquid hazardous waste

A hazardous waste pretreatment technology, applied in the direction of separation methods, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of large differences in indicators such as the combustion value and pH of hazardous waste, and the treatment capacity and treatment efficiency are not up to expectations. Set requirements, the quality of finished products is difficult to maintain stability, etc., to achieve uniform and stable product properties, reduce adverse effects, good economic benefits and safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1 As shown, the specific steps of using the pretreatment method of liquid hazardous waste of the present invention to process liquid hazardous waste are as follows:

[0039] S1: Warehousing identification: firstly identify the hazardous liquid waste from tank trucks and tons of barrels, and classify the hazard levels of liquid hazardous waste; identify and classify the hazards of the toxicity of liquid hazardous waste according to the WSDS database , among which highly toxic substances and substances with unknown components shall be sealed up and reported according to relevant specifications or returned to the original waste unit, and materials that meet the type of treatment of the unit shall be classified and recorded for storage;

[0040] S2: Treatment and storage of liquid hazardous waste raw materials: LDF coarse filter material is obtained after rough filtering the liquid hazardous waste from tank trucks and liquid hazardous waste from tons of barre...

Embodiment 2

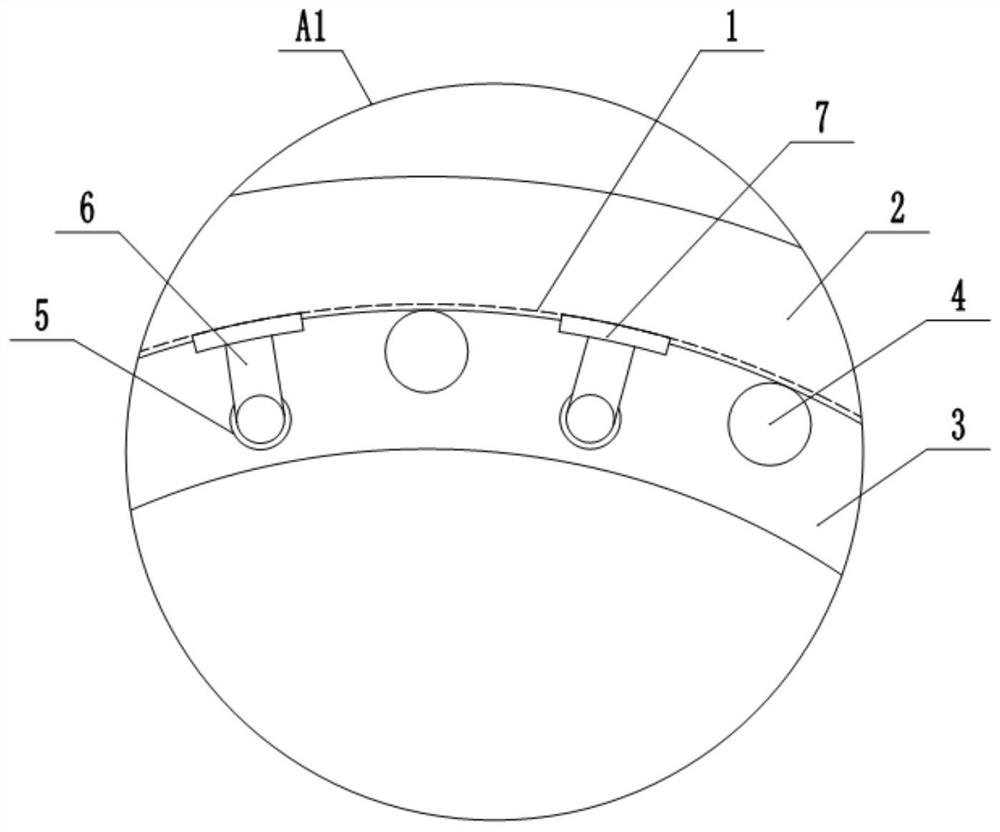

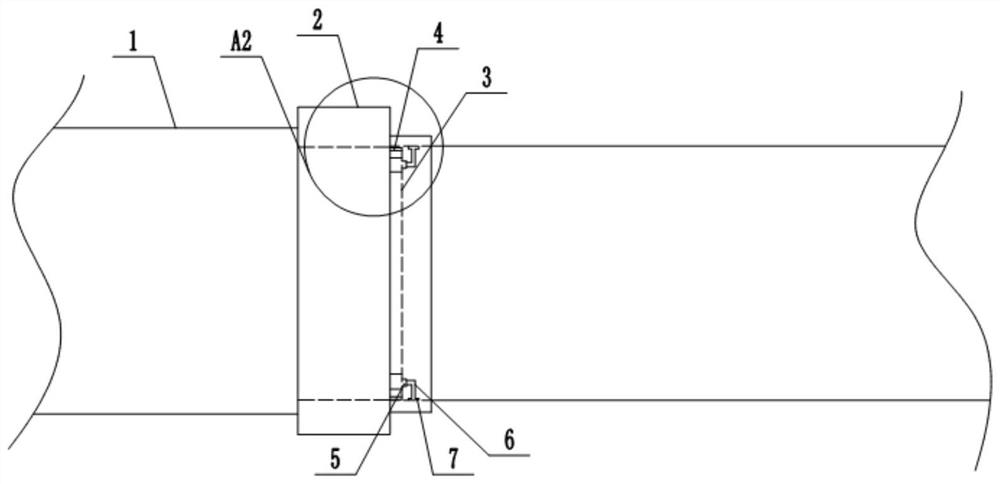

[0052] Such as Figure 1-Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the hazard of the toxicity of liquid hazardous waste is identified and classified according to the WSDS database, and the type and hazard level of liquid hazardous waste are determined. In addition, since the liquid hazardous waste is transported by the pipeline 1 in this technical solution, in order to avoid the problem of the pipeline 1 being blocked, the connection mode of the pipeline 1 and the structure of the connector are improved.

[0053] In this embodiment, the pipeline 1 is arranged in a spliced shape in subregions, and the two pipelines 1 are communicated through a regulating valve. The regulating valve includes a fixing part and an adjusting part. The fixing part in this embodiment can communicate with the pipeline 1 The fixed ring 2, the inner diameter of the fixed ring 2 is provided with a switch valve for opening and closing the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com