Method for testing breaking strength of glass fiber reinforced composite material workpiece

A technology of reinforced composite materials and glass fibers, applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, strength characteristics, etc., can solve problems such as structural design defects, affecting project progress, and insufficient strength, so as to reduce design The effects of processing costs, shortening the design and development cycle, and improving the qualified rate of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

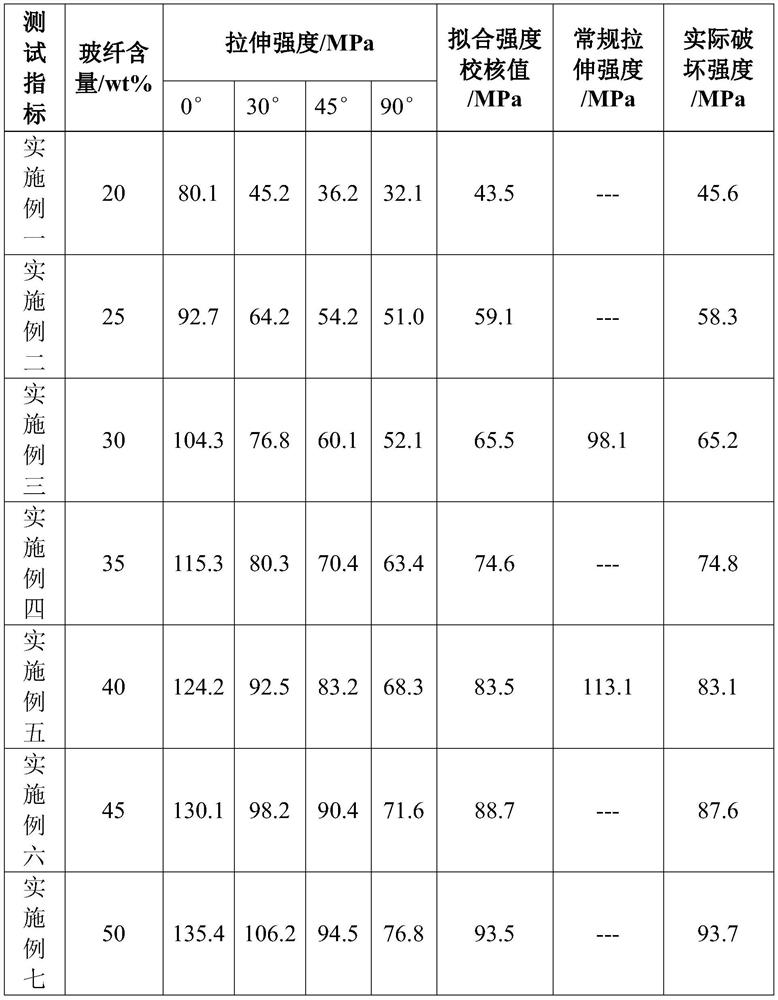

Embodiment 3

[0051] In Example 3, it can be found that the error between the conventional tensile strength value and the actual breaking strength value that is not processed by the method of the present invention is 33.5%, and the error between the calibration value obtained by using the method of the present invention and the actual breaking strength value is only 0.46% .

Embodiment 5

[0052] In Example 5, it can be found that the error between the conventional tensile strength value and the actual breaking strength value that is not processed by the method of the present invention is 26.5%, and the error between the calibration value obtained by using the method of the present invention and the actual breaking strength value is only 0.48% .

[0053] It can be seen that the existing national standard method of testing the tensile strength by injection molding into a spline cannot well reflect the failure strength that the actual part can withstand. The damage strength that can be withstood will lead to wrong estimation, which will lead to the occurrence of problems such as product misuse and vulnerability.

[0054] The equipment used in the method of the invention is simple, easy to implement and operate, reduces design and processing costs, shortens the design and development cycle of the entire product, improves the qualification rate of parts, greatly imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com