A kind of epoxy modified high temperature petrolatum anticorrosion paste and preparation method thereof

An epoxy modification and anti-corrosion paste technology, applied in epoxy resin coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of poor temperature resistance, unstable material performance, oil leakage, etc., and achieve good durability, The effect of good operating performance and maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

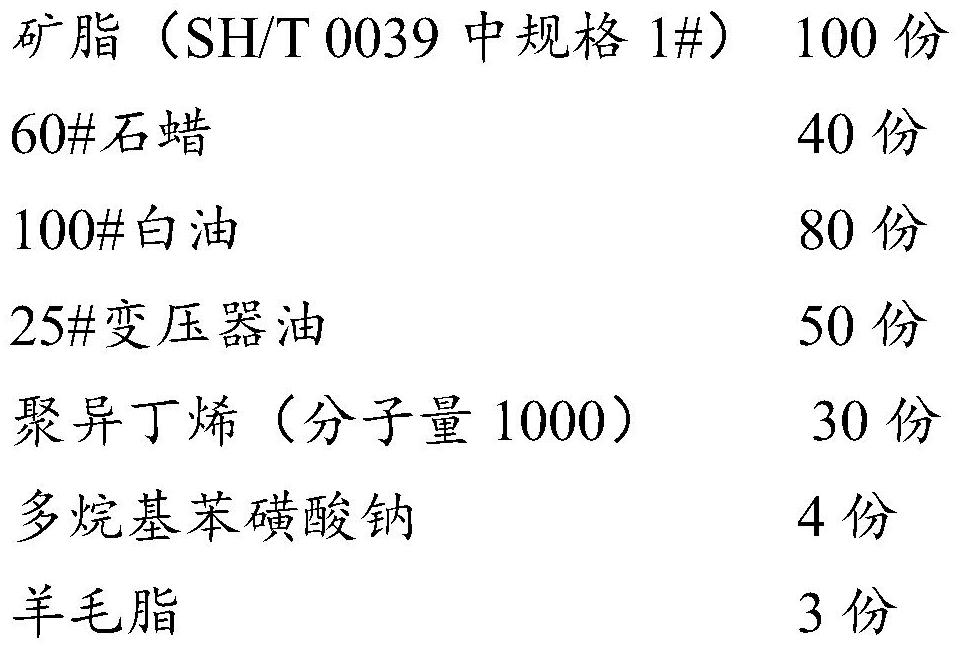

[0034] This embodiment provides an epoxy-modified high-temperature petrolatum anti-corrosion paste. The epoxy-modified high-temperature petrolatum anti-corrosion paste is composed of two components A and B, wherein:

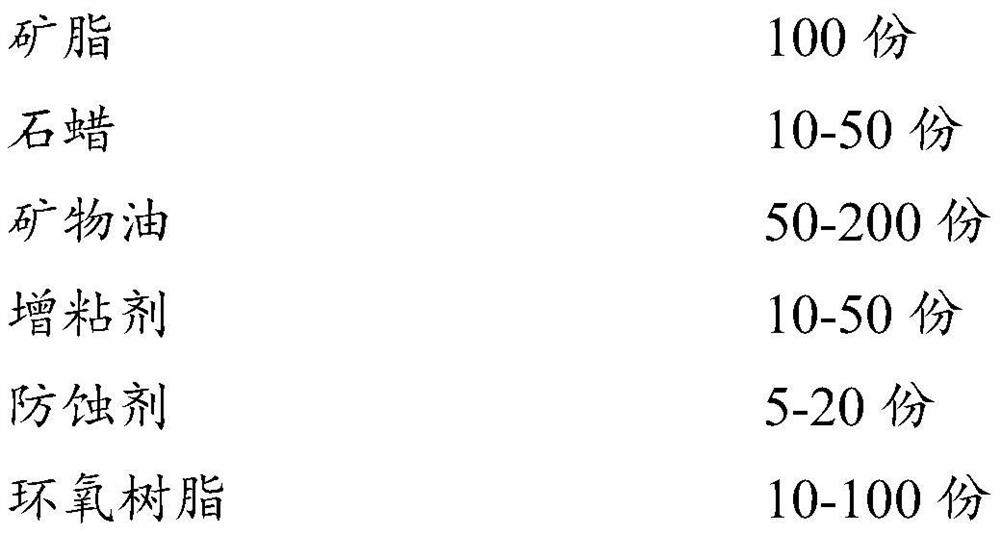

[0035] Component A is mainly prepared from the following raw materials in parts by weight:

[0036]

[0037]

[0038] Component B is mainly prepared from the following raw materials in parts by weight:

[0039] Modified fatty amine 50 parts

[0040] Polyetheramine curing agent 50 parts

[0041] 80 parts of 800 mesh light calcium.

[0042] The preparation method of the epoxy-modified high-temperature petrolatum anti-corrosion paste provided in this embodiment comprises the following steps:

[0043] To prepare component A:

[0044] (1) Add the above-mentioned petrolatum, paraffin, white oil, transformer oil, polyisobutylene, sodium polyalkylbenzene sulfonate, lanolin, aluminum stearate and benzimidazole into the stirring tank, heat to 110°C, and stir well...

Embodiment 2

[0052] This embodiment provides an epoxy-modified high-temperature petrolatum anti-corrosion paste. The epoxy-modified high-temperature petrolatum anti-corrosion paste is composed of two components A and B, wherein:

[0053] Component A is mainly prepared from the following raw materials in parts by weight:

[0054]

[0055]

[0056] Component B is mainly prepared from the following raw materials in parts by weight:

[0057]

[0058] The preparation method of the epoxy-modified high-temperature petrolatum anti-corrosion paste provided in this embodiment comprises the following steps:

[0059] To prepare component A:

[0060] (1) Add the above-mentioned petrolatum, paraffin, white oil, polyisobutylene, barium dinonylnaphthalene sulfonate, aluminum stearate and benzotriazole into the stirring tank, heat to 110°C, and stir evenly to obtain the base Petrolatum anti-corrosion paste;

[0061] (2) adding the above-mentioned bisphenol A type epoxy resin, polyether polyol g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com