Polypropylene warm edge spacing bar and preparation method thereof

A warm edge spacer and polypropylene technology, which is applied in the field of polymer composite materials, can solve the problems of easy warpage and die deposits, and achieve the effects of reducing surface floating fibers, small warpage deformation, and improving bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the polypropylene warm edge spacer described in the above scheme, comprising the steps of:

[0036] 1) mixing each raw material and performing extrusion, strand drawing, cooling, pelletizing and drying in sequence to obtain granular products;

[0037] 2) extruding the granular product obtained in the step 1) to obtain a polypropylene warm edge spacer.

[0038] In the invention, various raw materials are mixed and then extruded, drawn, cooled, pelletized and dried to obtain granular products. In the present invention, it is preferred to use a twin-screw extruder for extrusion, glass fiber and mica are transferred to the twin-screw extruder from the side feeder, and the remaining components are transferred to the twin-screw extruder from the main feeder middle. In the present invention, the temperature of the barrel of the extruder is preferably 200-220° C., and the extruder is extruded through the machine head ...

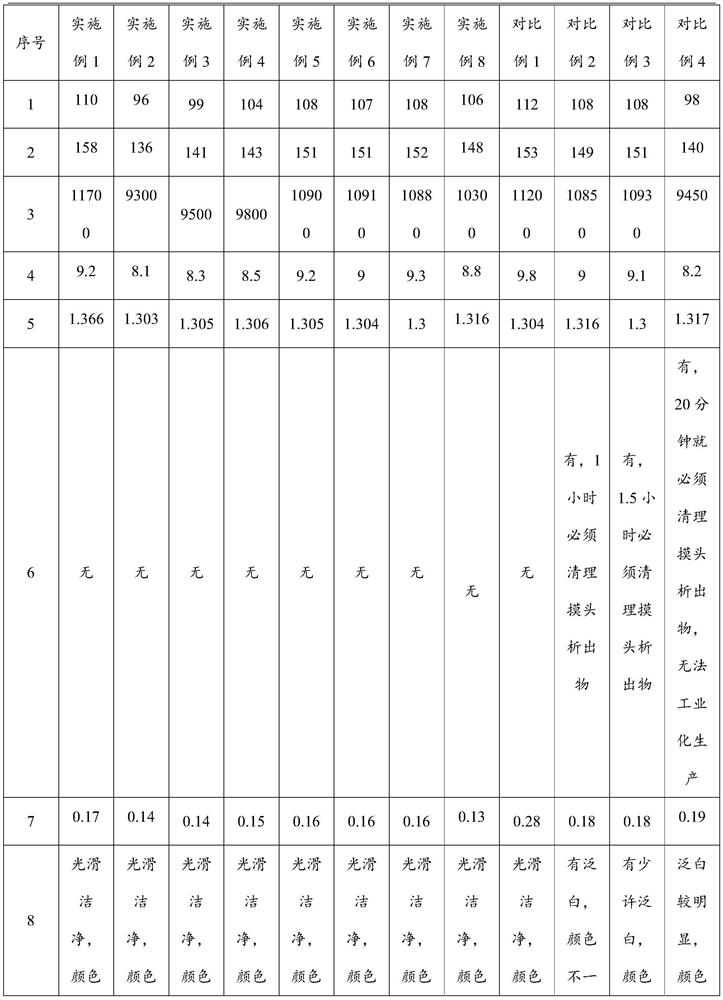

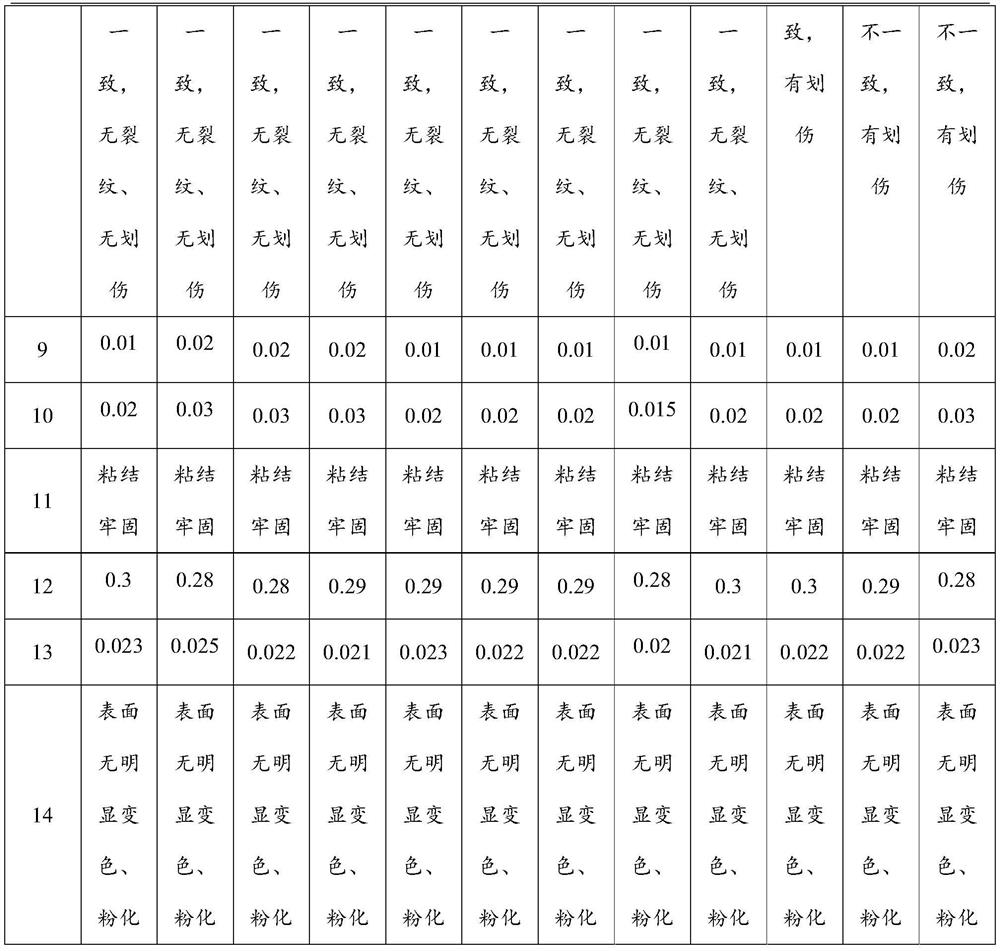

Embodiment 1

[0041] In parts by weight, weigh 35 parts of extrusion grade polypropylene, 10 parts of compatibilizer, 5 parts of mica, 50 parts of glass fiber, 0.15 part of antioxidant 1010, 0.15 part of antioxidant 168, 0.4 part of weather resistance agent, and 0.1 part of nuclear agent, 3 parts of silicone powder, 0.1 part of fluoroelastomer, 0.5 part of deodorant and 1 part of black masterbatch. The glass fiber and mica are transferred to the twin-screw extruder from the side feeder, and the remaining components are transferred to the twin-screw extruder from the main feeder. The temperature of the barrel of the extruder is controlled at 200-220°C, and it is extruded from the machine head after twin-screw high-speed shearing, mixing and cooling. After extrusion, strand drawing, cooling, pelletizing and drying are carried out in sequence to obtain granular products. The obtained granular product is then extruded to obtain a polypropylene warm edge spacer.

Embodiment 2

[0043] Except that the composition of the raw materials is different, other operating steps are exactly the same as in Example 1. The specific raw material composition is by weight, weighing 45 parts of extrusion grade polypropylene, 5 parts of compatibilizer, 15 parts of mica, 35 parts of glass fiber, 0.4 part of antioxidant 1010, 0.4 part of antioxidant 168, weather resistance agent 0.2 parts, 0.3 parts of nucleating agent, 1 part of silicone powder, 0.3 parts of fluoroelastomer, 0.1 parts of deodorant and 3 parts of black masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com