Mg-MOFs monocrystalline absorption material and preparation method and application thereof

An adsorption material, single crystal technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problem of destroying the pore structure, surface active sites and surface chemical properties of activated carbon materials, cumbersome preparation process, and difficult activation. and other problems, to achieve excellent adsorption effect, simple preparation process, and the effect of increasing activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a kind of Mg-MOFs ([Mg(Bpdc)(DMF) 2 ] n ) A preparation method for a single crystal adsorption material, comprising the following steps:

[0074] S1. Grind magnesium chloride into powder with a mortar, mix 2,2'-bipyridine-4,4'-dicarboxylic acid and magnesium chloride at a molar ratio of 2:5, add 5mL of DMF, stir well to obtain a mixed solution, put Ultrasound into the ultrasound machine for 30 minutes;

[0075] Wherein, the ratio of the volume of DMF to the amount of 2,2'-bipyridine-4,4'-dicarboxylic acid is 20:1mL / mmol;

[0076] S2. After sealing the mixed solution of S1 in the inner liner of the reactor, place the reactor in an electric blast drying oven (SY101BS-OD-C-CX), raise the temperature to 120°C at 30°C / h, and keep it warm for 48h. Then cool down to 30°C at 2.5°C / h;

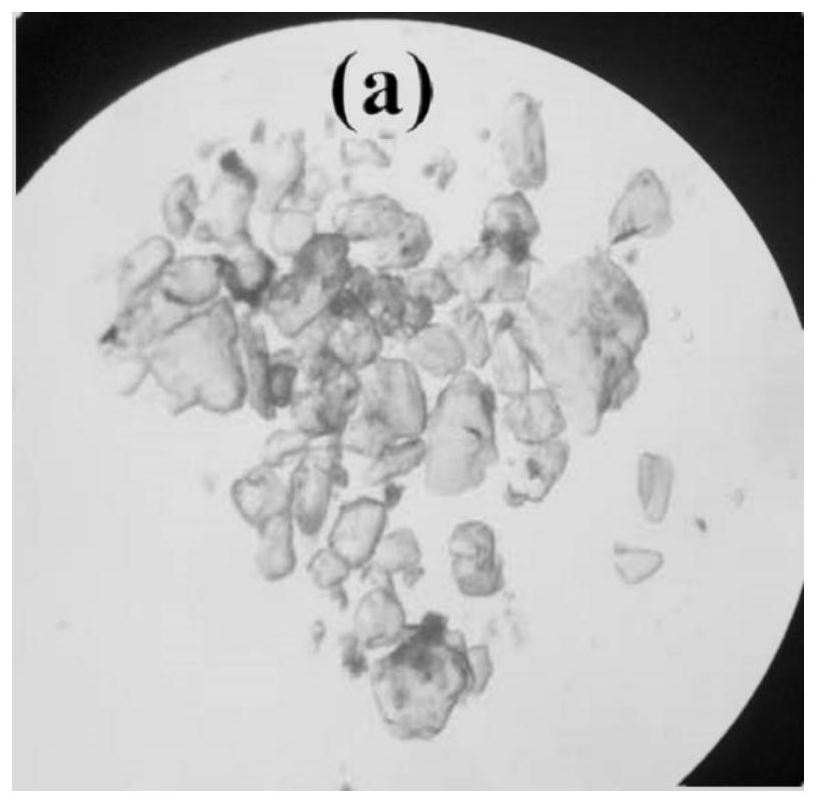

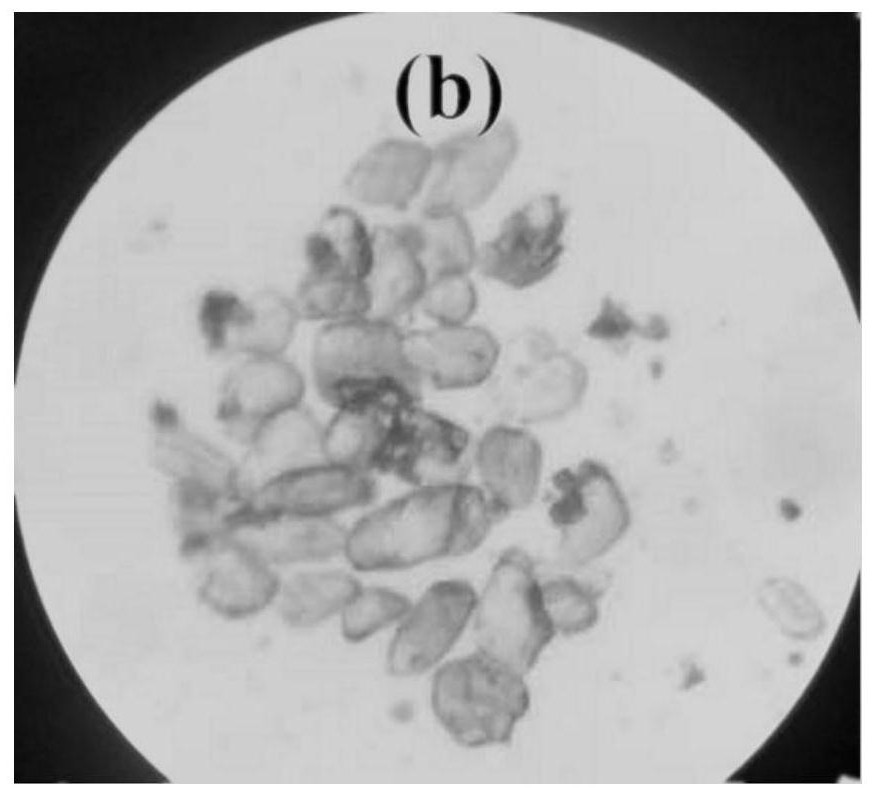

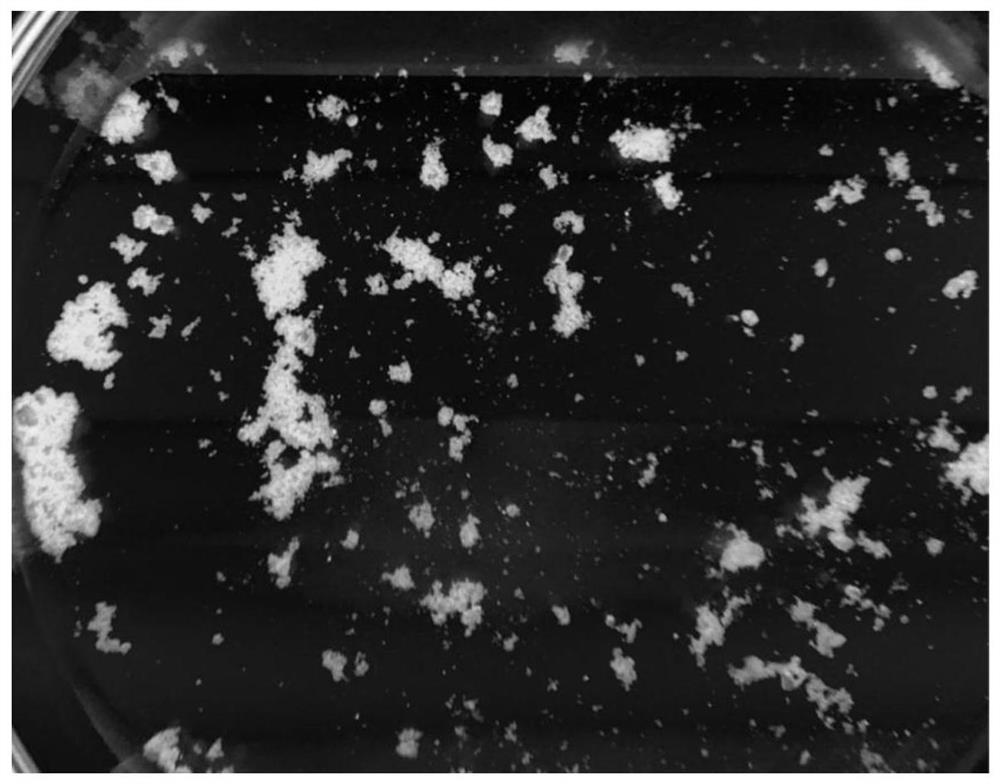

[0077] S3. Wash the reaction product of S2 with DMF for 3-5 times, then observe and screen the Mg-MOFs adsorption material with a specific structure under a microscop...

Embodiment 2

[0104] The present embodiment provides a kind of [Mg(Bpdc)(DMF) 2 ] n A method for preparing a single crystal adsorption material, comprising the following steps:

[0105] S1. Grind magnesium chloride into powder with a mortar, mix 2,2'-bipyridine-4,4'-dicarboxylic acid and magnesium chloride at a molar ratio of 1:10, add DMF, stir well, and obtain a mixed solution, put Ultrasound in the ultrasound machine for 30 minutes;

[0106] The ratio of the volume of DMF to the amount of 2,2'-bipyridyl-4,4'-dicarboxylic acid is 20:1mL / mmol;

[0107] S2. After sealing the mixed solution of S1 in the inner liner of the reactor, place the reactor in an electric blast drying oven (SY101BS-OD-C-CX), raise the temperature to 120°C at 30°C / h, and keep it warm for 48h. Then cool down to 30°C at 2.5°C / h;

[0108] S3. Wash the reaction product of S2 with DMF for 3-5 times, then observe and screen the Mg-MOFs adsorption material with a specific structure under a microscope, pick crystals with ...

Embodiment 3

[0110] The present embodiment provides a kind of [Mg(Bpdc)(DMF) 2 ] n A method for preparing a single crystal adsorption material, comprising the following steps:

[0111] S1. Grind magnesium chloride into powder with a mortar, mix 2,2'-bipyridine-4,4'-dicarboxylic acid and magnesium chloride at a molar ratio of 4:5, add DMF, stir well, and obtain a mixed solution, put Ultrasound in the ultrasound machine for 30 minutes;

[0112] The ratio of the volume of DMF to the amount of 2,2'-bipyridyl-4,4'-dicarboxylic acid is 20:1mL / mmol;

[0113] S2. After sealing the mixed solution of S1 in the inner liner of the reactor, place the reactor in an electric blast drying oven (SY101BS-OD-C-CX), raise the temperature to 120°C at 30°C / h, and keep it warm for 48h. Then cool down to 30°C at 2.5°C / h;

[0114] S3. Wash the reaction product of S2 with DMF for 3-5 times, then observe and screen the Mg-MOFs adsorption material with a specific structure under a microscope, pick crystals with r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com