Treatment system and method for recovering methylamine/ethylamine from amine-containing wastewater

A technology of recovery and treatment of ethylamine, which is applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of increased difficulty in sewage treatment, environmental pollution, air secondary pollution, etc., and achieve significant economic and social benefits and process flow Effects with simple, easy-to-operate controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

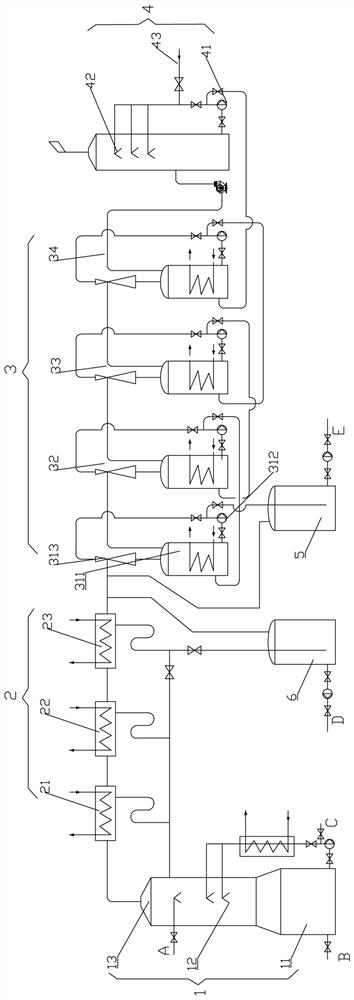

[0032] Embodiment 1: A kind of amination production wastewater treatment system

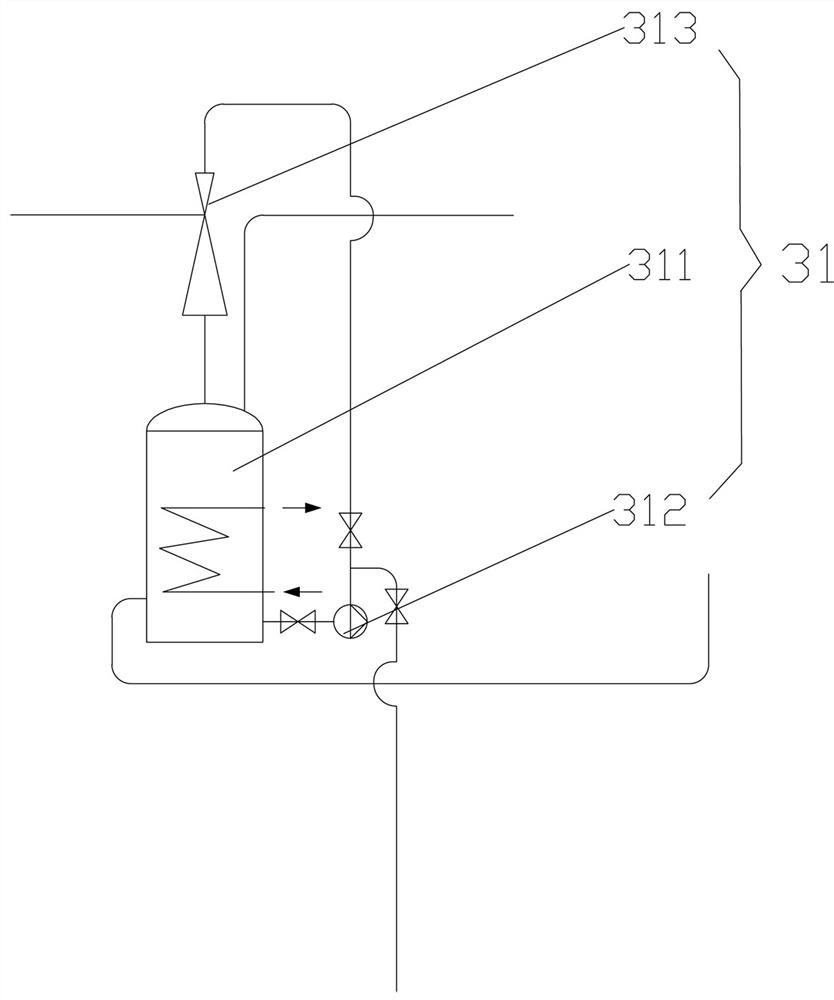

[0033] like figure 1 As shown: the amination production wastewater treatment system includes an amine gasification tower 1, a multi-stage condensation device 2, a multi-stage negative pressure absorption device 3 and a tail gas absorption tower 4 connected in sequence.

[0034] The amine gasification tower 1 is provided with a heating unit 11, a liquid distribution unit 12 and a reflux unit 13 in sequence from bottom to top; the heating unit 11 is heated by steam, and the heating temperature is 85-105°C; An atomizing nozzle is provided so that the atomized particle size is 100-1000 mm; a packing layer is provided at the bottom of the liquid distribution unit 12, and the packing is a conventional irregular packing, mainly stainless steel Raschig ring, Pall ring and stepped ring, etc., which are resistant to amine gas Corrosive materials; the lower part of the packing layer is equipped with a flus...

Embodiment 2

[0045] Embodiment 2: A kind of treatment method of amination production wastewater

[0046] The treated wastewater is the amination wastewater of D301 anion resin of an ion exchange resin enterprise. The pH of the amination wastewater is 8-9, and its organic components are mainly dimethylamine, methylal, methanol and the like after testing. Methylal is relatively stable to alkali. When heated together with dilute hydrochloric acid, it is easily decomposed into formaldehyde and methanol, and reacts with concentrated hydrochloric acid to generate methyl chloride, which normally exists in the form of formaldehyde in water. Detect a batch of production wastewater. The content of dimethylamine (testing standard: methylamine solution test HGT 2971-1999; determination of low-carbon fatty amine content GB / T 23961-2009) in wastewater is 0.71%, formaldehyde (testing standard: DB41T1425- 2017 Determination of Methylal Content in Gasoline (DB41T1425-2017) 0.15%, COD (Testing Standard: De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com