Novel asphalt concrete and preparation process thereof

A new type of asphalt concrete technology, applied in the field of concrete, can solve the problems of difficult polymer dispersion, high mixing temperature, asphalt aging, etc., and achieve the effects of improving anti-aging performance, improving adsorption performance, and strengthening bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

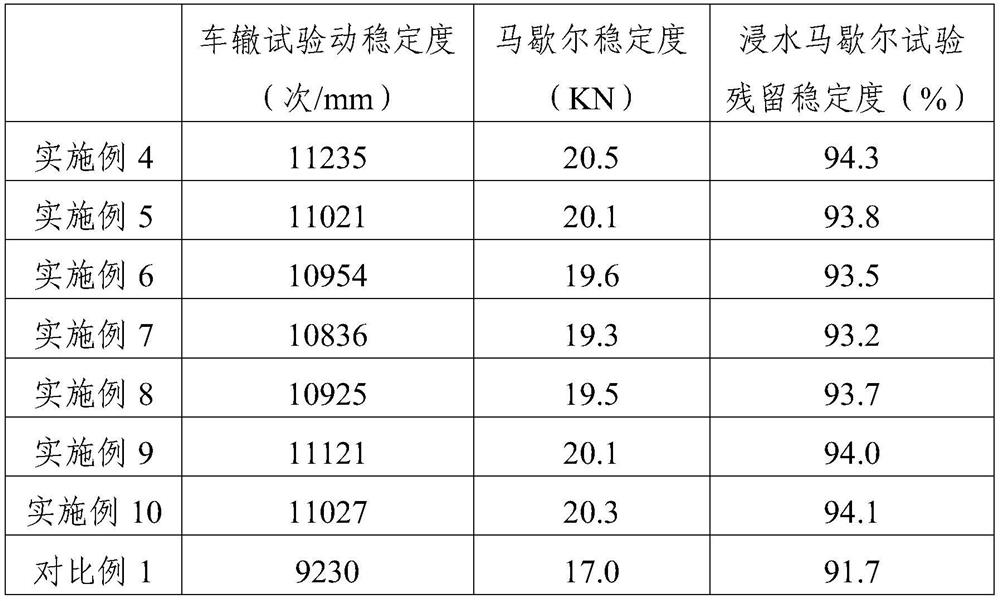

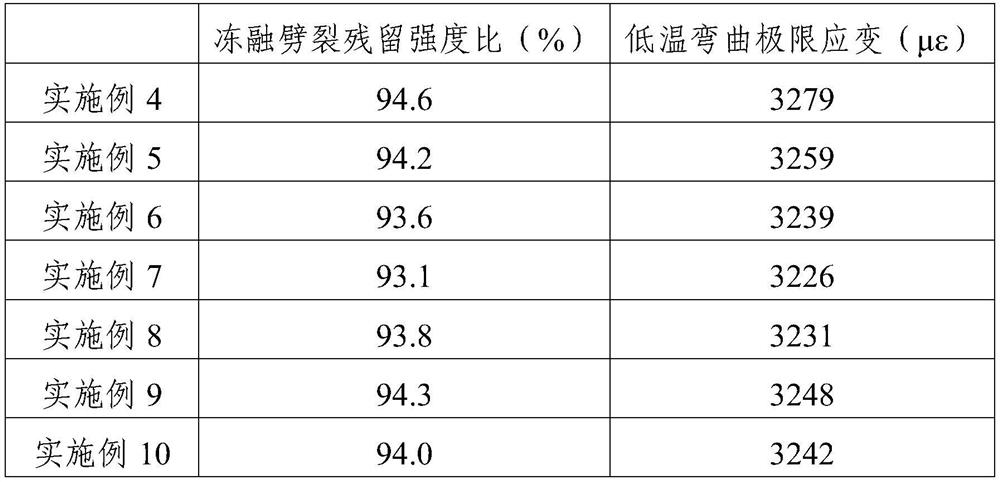

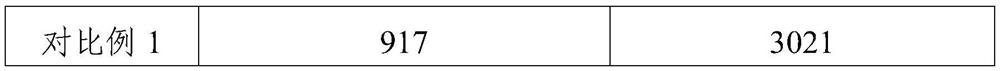

Examples

Embodiment 1

[0032] Example 1: Preparation of bentonite-supported nano-SiC-TaC composite material

[0033] Bentonite-loaded nano-SiC-TaC composites were prepared by the following method:

[0034] (1) Add a glucose solution with a mass solubility of 30% to the bentonite. After the bentonite is completely wetted, place it in an aerobic atmosphere for calcination at 800° C. for 2 hours, and cool to room temperature with the furnace to obtain porous bentonite.

[0035] (2) Use ethyl orthosilicate as the silicon source, mix it with absolute ethanol, deionized water and dilute hydrochloric acid, the molar ratio of ethyl orthosilicate, absolute ethanol, deionized water, and hydrogen chloride is 1:2.5 : 2.5: 0.01 to obtain solution A; using tantalum pentachloride as the tantalum source, dissolve it in absolute ethanol to form saturated solution B; prepare a glucose aqueous solution with a mass concentration of 30% to obtain solution C.

[0036]Mix solution B and solution A, then add porous benton...

Embodiment 2

[0039] Example 2: Preparation of bentonite-loaded nano-SiC-TaC composite material

[0040] Bentonite-loaded nano-SiC-TaC composites were prepared by the following method:

[0041] (1) Add a glucose solution with a mass solubility of 30% to the bentonite. After the bentonite is completely wetted, place it at 750° C. for calcination for 2 hours in an aerobic atmosphere, and cool to room temperature with the furnace to obtain porous bentonite.

[0042] (2) Use ethyl orthosilicate as the silicon source, mix it with absolute ethanol, deionized water and dilute hydrochloric acid, the molar ratio of ethyl orthosilicate, absolute ethanol, deionized water, and hydrogen chloride is 1:2.5 : 2.5: 0.01 to obtain solution A; using tantalum pentachloride as the tantalum source, dissolve it in absolute ethanol to form saturated solution B; prepare a glucose aqueous solution with a mass concentration of 30% to obtain solution C.

[0043] Mix solution B and solution A, then add porous bentonit...

Embodiment 3

[0046] Embodiment 3: Preparation of modified basalt chopped fibers

[0047] The modified basalt chopped fiber is prepared by the following method: the basalt chopped fiber is soaked in 50% acetic acid aqueous solution for 1 hour, then filtered, washed with water, and dried at 100°C; Add KH550 and ethanol into water, heat to 45±2°C, add basalt chopped fibers, stir for 1 hour, filter and dry at 100°C to obtain modified basalt chopped fibers. The mass ratio of silane coupling agent KH550, ethanol and water is 1:4:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com