Electric auxiliary bending forming process method for high-temperature titanium alloy grid rib wall plate

A high-temperature titanium alloy and forming technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of residual deformation, high processing temperature, cracking at the root of ribs, etc., and achieve the effect of improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The electric-assisted press-bending process method of the high-temperature titanium alloy grid rib wall plate of the present invention comprises the following steps:

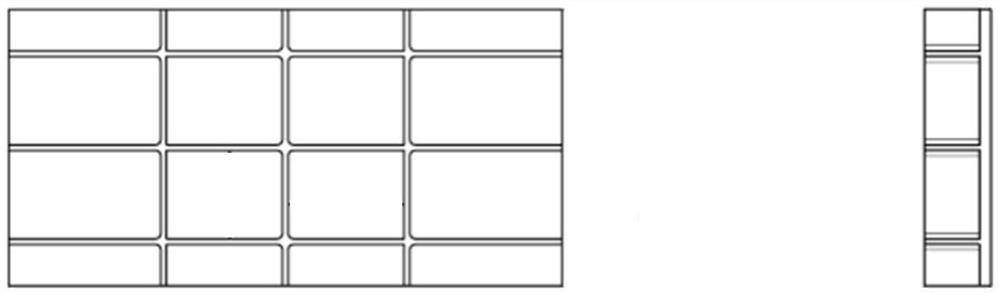

[0042] S1, milling high-temperature titanium alloy thick plate into planar grid rib panel 1 with vertical and horizontal grid ribs and web structure; figure 1 shown;

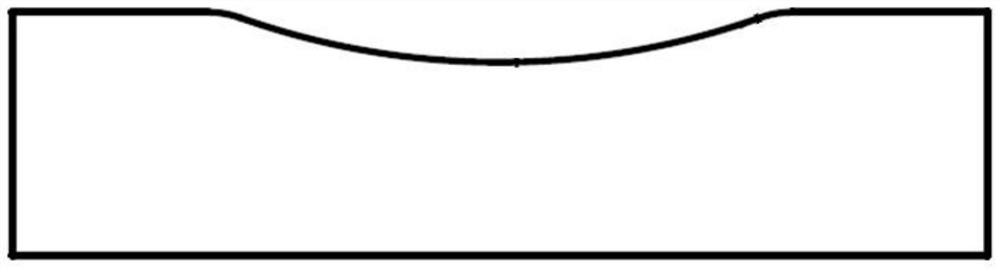

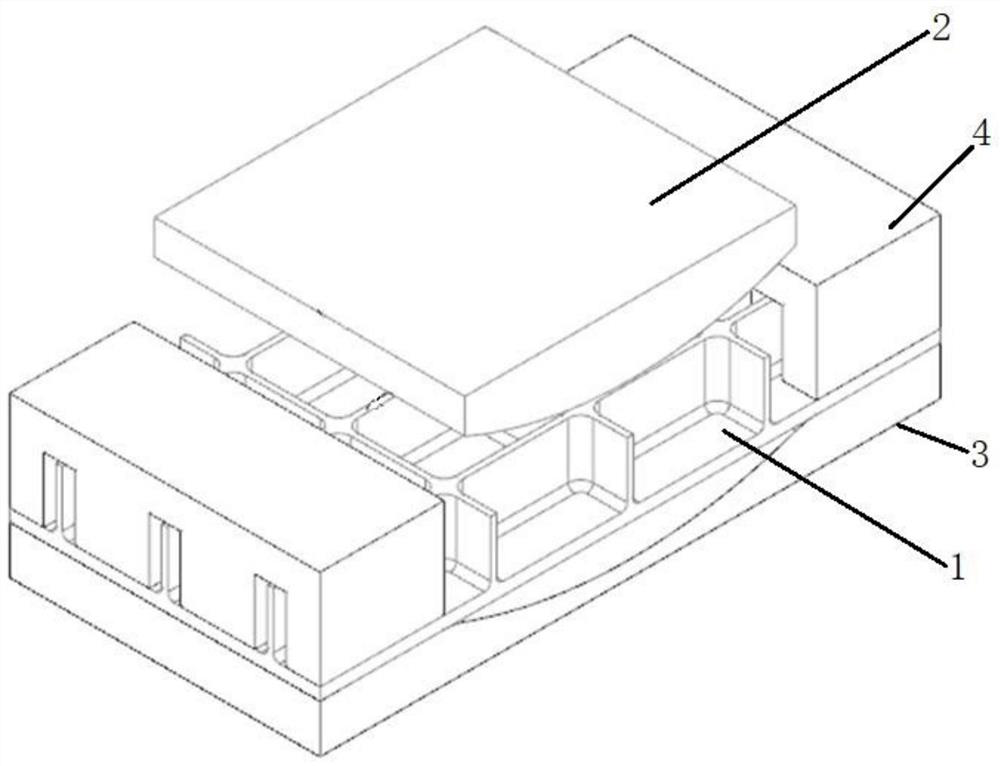

[0043] S2, setting the bending punch 2 on the upper backing plate of the hydraulic press, such as figure 2The shown bending die 3 is set on the lower backing plate of the hydraulic press, and the bending punch 2 is aligned with the bending die 3, and the planar grid rib wall plate 1 is positioned on the On the bending die 3, the end face of the planar grid rib panel 1 is provided with the vertical and horizontal grid ribs upward;

[0044] S3, by connecting the two electrodes 4 of the pulse current generator, respectively contacting the two ends of the planar grid rib wall panel 1 to press the edges, and calibrating and fixing the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com