Preparation method for synthesizing lanthanum hafnate powder by using sol-gel process

A technology of sol-gel method and lanthanum hafnate, applied in the field of preparation of sol-gel method to synthesize lanthanum hafnate powder, can solve the problems of easy mixing of impurities, high energy consumption, grain growth and the like, and achieve the synthesis of powder Controllable chemical composition, low calcination temperature and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

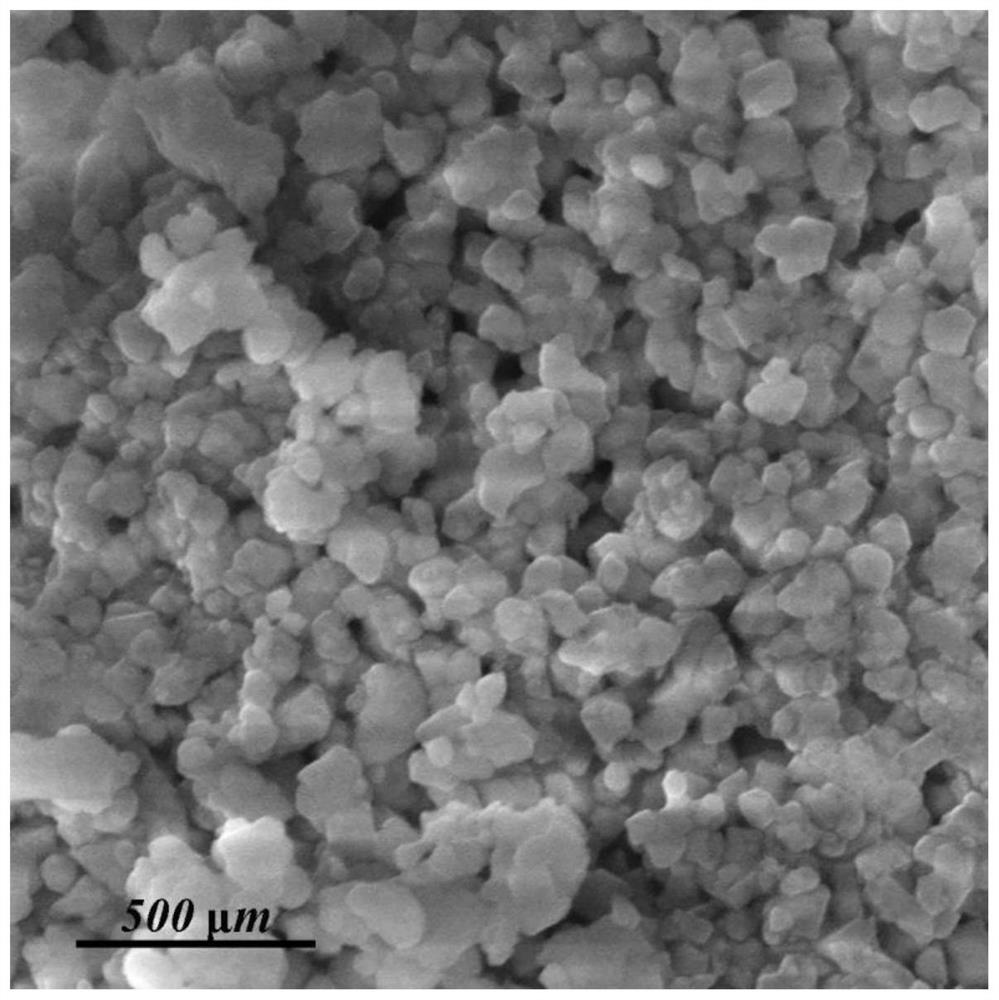

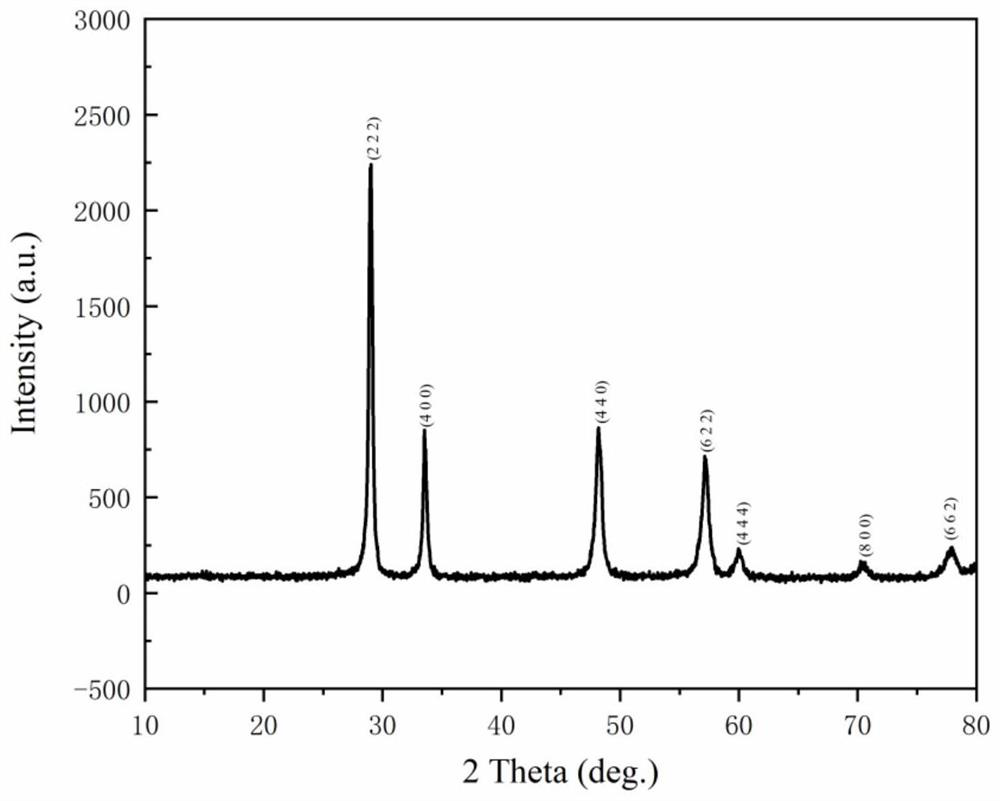

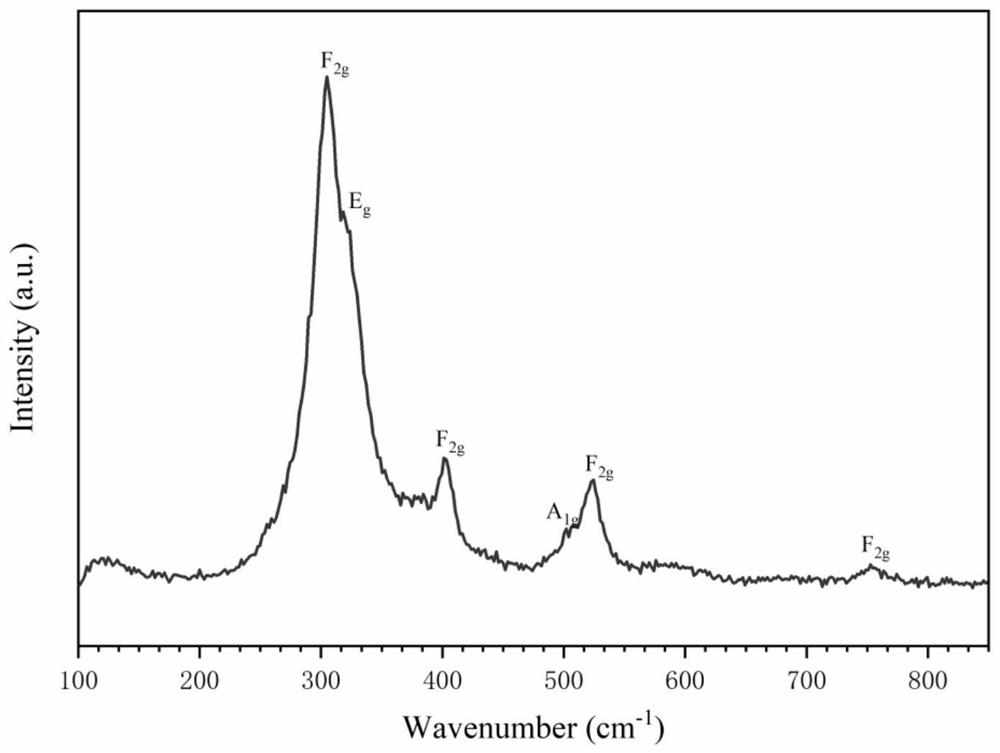

Image

Examples

Embodiment 1

[0026] A kind of molten salt method of the present embodiment synthesizes La 2 f 2 o 7 Powder preparation method.

[0027] Step 1: Weigh a certain amount of hafnium tetrachloride (HfCl 4 ) and hydrated lanthanum nitrate (La(NO 3 ) 3 ·xH 2 O), ensure that the molar ratio of hafnium-lanthanum element is 1:1, be dissolved in deionized water with a mass ratio of hafnium-lanthanum compound and deionized water of 1:5-15, fully stir for 1-2h, The molar ratio is 1:1-2, and the citric acid powder is weighed and dissolved in the mixed solution, and the mixed solution is placed in a constant temperature water bath at a temperature of 50-80°C and stirred for 1-3 hours to form a sol.

[0028] Step 2: According to the 1:1 molar ratio of ethylene glycol and citric acid, weigh a certain amount of ethylene glycol solution and pour it into the solution obtained in step 1, and place it in a constant temperature water bath at 70-90°C for evaporation and stirring 2 to 4 hours to form a gel....

Embodiment 2

[0031] A kind of molten salt method of the present embodiment synthesizes La 2 f 2 o 7 Powder preparation method.

[0032] Step 1: Weigh a certain amount of hafnium tetrachloride (HfCl 4 ) and hydrated lanthanum nitrate (La(NO 3 ) 3 ·xH2 O), ensure that the molar ratio of hafnium-lanthanum element is 1:1, be dissolved in deionized water with a mass ratio of hafnium-lanthanum compound and deionized water of 1:5-15, fully stir for 1-2h, The molar ratio is 1:1-2, and the citric acid powder is weighed and dissolved in the mixed solution, and the mixed solution is placed in a constant temperature water bath at a temperature of 50-80°C and stirred for 1-3 hours to form a sol.

[0033] Step 2: According to the molar ratio of ethylene glycol and citric acid as 1:2, weigh a certain amount of ethylene glycol solution and pour it into the solution obtained in step 1, and place it in a constant temperature water bath at 70-90°C for evaporation and stirring 2 to 4 hours to form a gel...

Embodiment 3

[0036] A kind of molten salt method of the present embodiment synthesizes La 2 f 2 o 7 Powder preparation method.

[0037] Step 1: Weigh a certain amount of hafnium tetrachloride (HfCl 4 ) and hydrated lanthanum nitrate (La(NO 3 ) 3 ·xH 2 O), ensure that the molar ratio of hafnium-lanthanum element is 1:1, be dissolved in deionized water with a mass ratio of hafnium-lanthanum compound and deionized water of 1:5-15, fully stir for 1-2h, The molar ratio is 1:1-2, and the citric acid powder is weighed and dissolved in the mixed solution, and the mixed solution is placed in a constant temperature water bath at a temperature of 50-80°C and stirred for 1-3 hours to form a sol.

[0038] Step 2: According to the 1:3 molar ratio of ethylene glycol and citric acid, weigh a certain amount of ethylene glycol solution and pour it into the solution obtained in step 1, and place it in a constant temperature water bath at 70-90°C for evaporation and stirring 2 to 4 hours to form a gel....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com