An in-situ laser cleaning method for aircraft non-conductive composite coating

A technology of laser cleaning and composite coating, applied in the field of laser cleaning, can solve problems such as high labor intensity, low production efficiency, and damage to substrate materials, and achieve the effects of good electrical connection performance, high cleaning efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

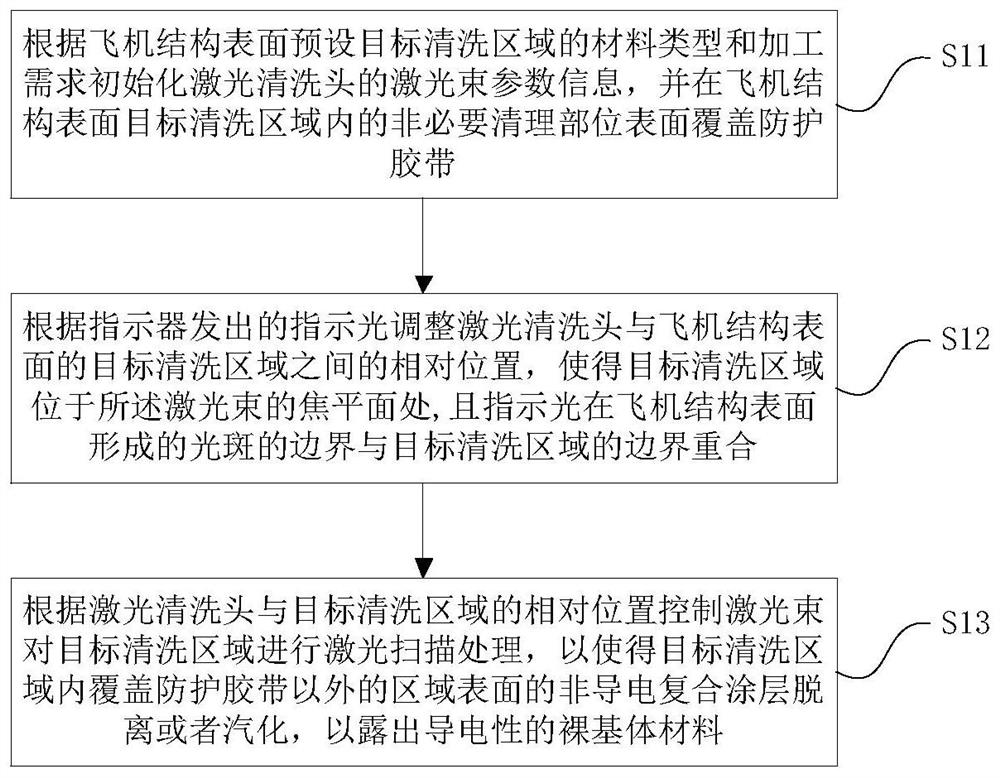

[0037] Such as figure 1 Shown, a kind of in-situ laser cleaning method of aircraft non-conductive composite coating, comprises the steps:

[0038] S11: Initialize the laser beam parameter information of the laser cleaning head according to the material type and processing requirements of the preset target cleaning area on the surface of the aircraft structure, and cover the surface of the non-essential cleaning parts in the target cleaning area with protective tape;

[0039] For example, the irradiation energy density of the laser beam is set so that the energy density of the laser beam is within the range of the damage threshold and the cleaning threshold of the substrate at the cleaning site, where the damage thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com