Preparation method of a gas-conducting and hydrogen-evolving material with a gradually expanding pore structure

A pore structure and hydrogen material technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of high-purity hydrogen collection difficulties, high energy consumption, low efficiency, etc., and achieve excellent space efficiency. Effects on catalytic activity and gas conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

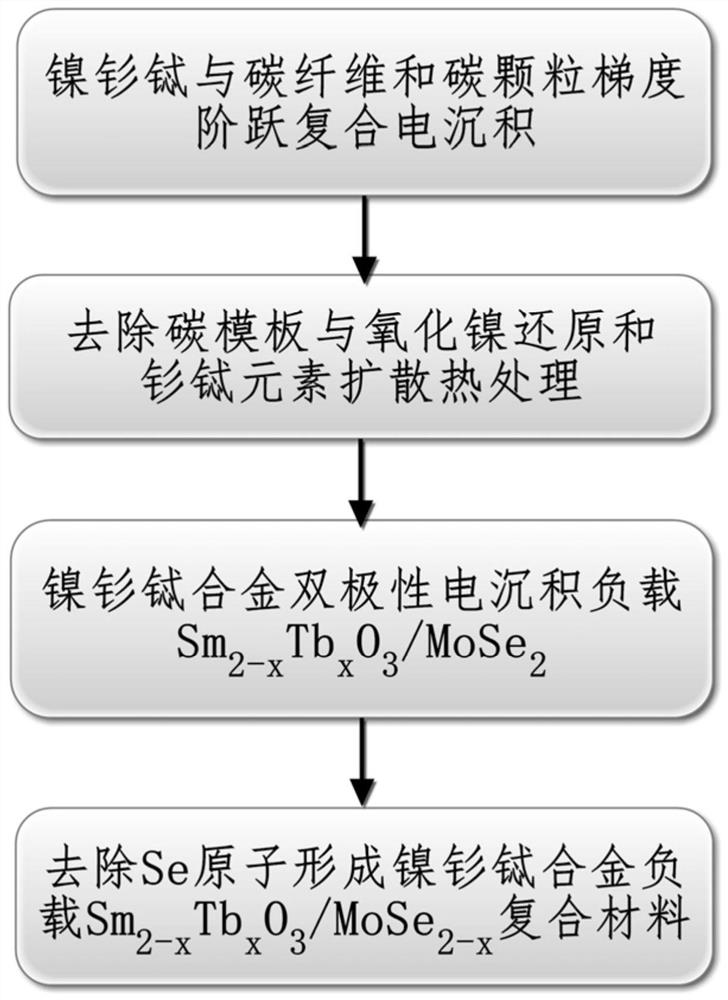

[0029] refer to figure 1 , the invention provides a method for preparing a gas-conducting and hydrogen-evolving material with a gradually expanding pore structure, comprising the following steps:

[0030] Step [1] Gradient-step composite electrodeposition of nickel, samarium and terbium with carbon fibers and carbon particles, specifically including the following operations:

[0031] a1. Preparation of composite electrodeposition solution: nickel formate, samarium trifluoromethanesulfonate, terbium nitrate hexahydrate, potassium dodecyl sulfate, carbon particles (5-10 μm in particle size) and carbon fibers (150-200 nm in diameter) , length of 10-30 μm) into deionized water, ultrasonically stirred for 2-6 hours to form a uniform suspension, and then added chloral to complete the preparation of the composite electrodeposition solution, the concentration of nickel formate in the composite electrodeposition solution 180-270g / L, samarium trifluoromethanesulfonate concentration 90-...

Embodiment 1

[0044] Preferred Embodiment 1 of the present invention provides a method for preparing a gas-conducting and hydrogen-evolving material with a gradually expanding pore structure, comprising the following steps:

[0045] Step [1] Gradient-step composite electrodeposition of nickel, samarium and terbium with carbon fibers and carbon particles, specifically including the following operations:

[0046] a1. Preparation of composite electrodeposition solution: nickel formate, samarium trifluoromethanesulfonate, terbium nitrate hexahydrate, potassium dodecyl sulfate, carbon particles (6 μm in particle size) and carbon fibers (180 nm in diameter and 25 μm in length) ) into deionized water, ultrasonically stirred for 4 hours to form a uniform suspension, then added chloral, thereby completing the preparation of the composite electrodeposition solution, the concentration of nickel formate in the composite electrodeposition solution was 200g / L, trifluoromethane The concentration of samari...

Embodiment 2

[0087] The preferred embodiment 2 of the present invention provides a method for preparing a gas-conducting and hydrogen-evolving material with a gradually expanding pore structure, comprising the following steps:

[0088]Step [1] Gradient-step composite electrodeposition of nickel, samarium and terbium with carbon fibers and carbon particles, specifically including the following operations:

[0089] a1. Preparation of composite electrodeposition solution: nickel formate, samarium trifluoromethanesulfonate, terbium nitrate hexahydrate, potassium dodecyl sulfate, carbon particles (6 μm in particle size) and carbon fibers (160 nm in diameter and 12 μm in length) ) into deionized water, ultrasonically stirred for 2 hours to form a uniform suspension, then added chloral, thereby completing the preparation of the composite electrodeposition solution, the concentration of nickel formate in the composite electrodeposition solution was 182g / L, trifluoromethane The concentration of sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com