Damping bridge support and preparation method

A bridge bearing and water reducing agent technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of bubble flow of seismic capacity, weaken the shock absorption effect of the bearing, etc., to improve the shock absorption capacity, structural stability, reduce The effect of heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

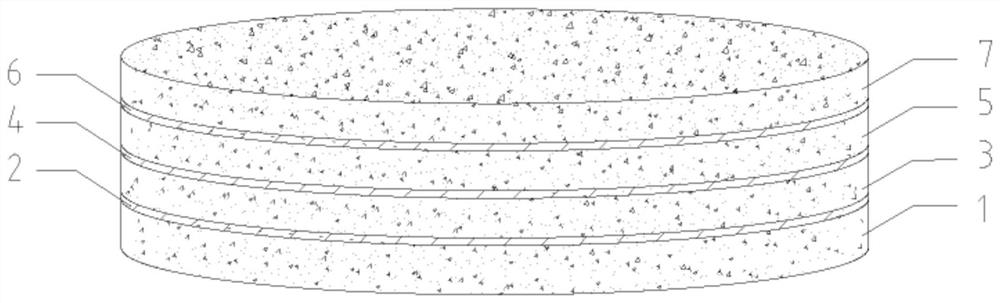

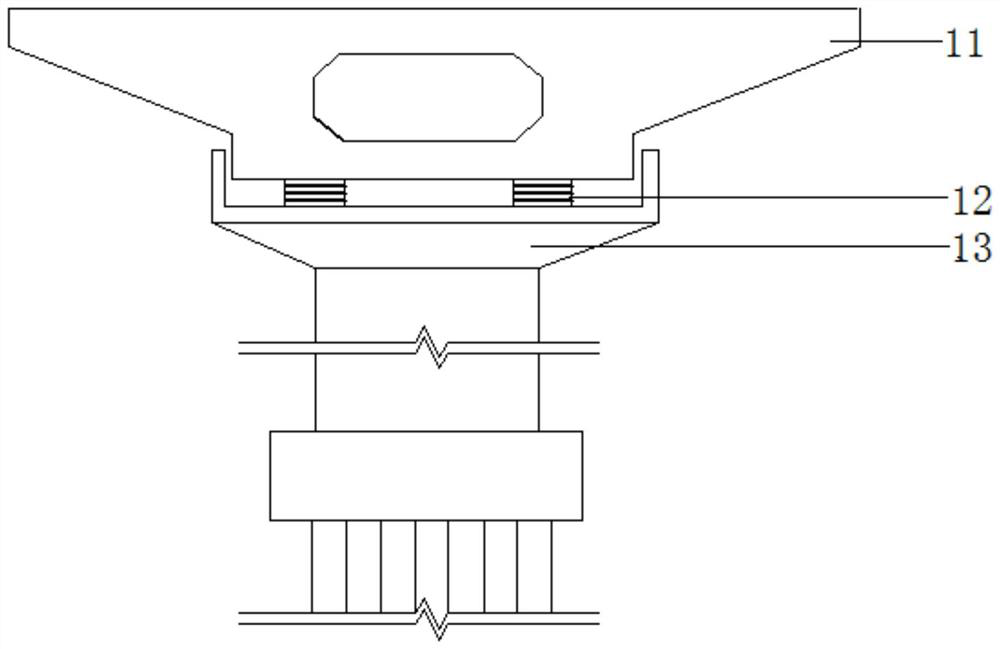

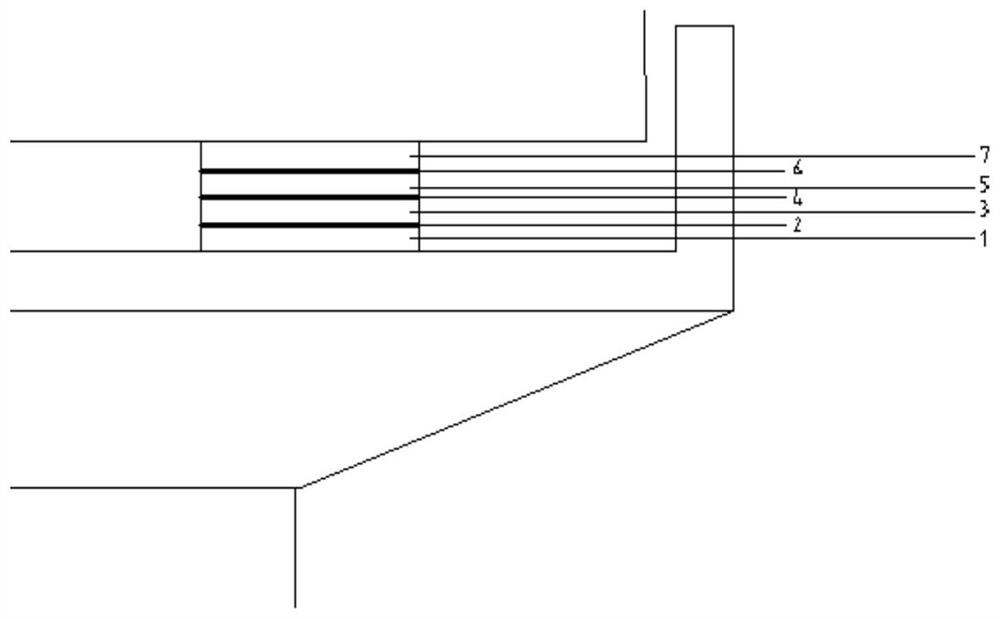

[0019] Such as Figure 1-3 As shown, the vibration-absorbing bridge bearing disclosed in the present invention includes seven functionally graded layers, which are in an integral cylindrical structure, and sequentially include a first foam concrete layer 1, a first steel plate layer 2, and a second foam concrete layer 3 from bottom to top. , the second steel plate layer 4, the third foam concrete layer 5, the third steel plate layer 6 and the fourth foam concrete layer 7, the diameter of the steel plate is 250mm ~ 400mm, the thickness is 2 ~ 4mm, the steel material is selected from Q235 steel plate, and the diameter of the foam concrete layer is 250-400mm, thickness 20-25mm, density controlled at 400-1000kg / m 3 , Raw materials The raw materials of foam concrete materials include Portland cement, perlite, ore powder, fly ash, water reducer, basalt fiber, foam and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com