Ultrathin head stamping process

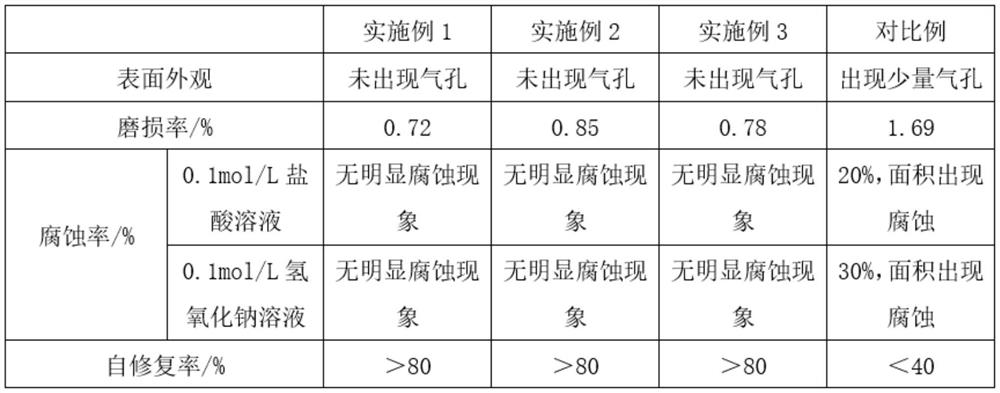

A head, ultra-thin technology, applied in the field of stamping, can solve the problems of poor wear resistance and corrosion resistance of the head, prone to some small holes, short service life, etc., to improve quality, improve surface protection effect, improve high temperature Effect of carbonized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A stamping process of an ultra-thin head, comprising the following steps:

[0052] Step 1. Preheating treatment: place the head to be stamped at 200-300°C for heat treatment for 0.1-0.5 hours to obtain the preheated head body;

[0053] Step 2. Mold treatment: apply a release agent on both the inner surface of the die and the outer surface of the punch, and then place it at 90°C to 120°C for 0.1 to 0.5h to obtain the treated die and the treated die. punch;

[0054] Step 3, first stamping: placing the preheated head blank body inside the processed die, pressing down the processed punch for stamping, and obtaining a head blank connected to the die ;

[0055] Step 4, heat treatment: place the head blank body treated in step 3 together with the die under the condition of 180-200°C for heat treatment for 0.1-0.5h;

[0056] Step 5, Stamping again: pressing down the punch again to stamp the head body that has been heat-treated in Step 4;

[0057] Step 6, cooling treatment: ...

Embodiment 2

[0092] A stamping process of an ultra-thin head, comprising the following steps:

[0093] Step 1. Preheating treatment: place the head to be stamped at 200-300°C for heat treatment for 0.1-0.5 hours to obtain the preheated head body;

[0094] Step 2. Mold treatment: apply a release agent on both the inner surface of the die and the outer surface of the punch, and then place it at 90°C to 120°C for 0.1 to 0.5h to obtain the treated die and the treated die. punch;

[0095] Step 3, first stamping: place the preheated head blank body inside the processed die, press down the processed punch to punch, and obtain the head blank connected with the die ;

[0096] Step 4, heat treatment: place the head blank body treated in step 3 together with the die under the condition of 180-200°C for heat treatment for 0.1-0.5h;

[0097] Step 5, Stamping again: pressing down the punch again to stamp the head body that has been heat-treated in Step 4;

[0098] Step 6, cooling treatment: take out...

Embodiment 3

[0133] A stamping process of an ultra-thin head, comprising the following steps:

[0134] Step 1. Preheating treatment: place the head to be stamped at 200-300°C for heat treatment for 0.1-0.5 hours to obtain the preheated head body;

[0135] Step 2. Mold treatment: apply a release agent on both the inner surface of the die and the outer surface of the punch, and then place it at 90°C to 120°C for 0.1 to 0.5h to obtain the treated die and the treated die. punch;

[0136] Step 3, first stamping: placing the preheated head blank body inside the processed die, pressing down the processed punch for stamping, and obtaining a head blank connected to the die ;

[0137] Step 4, heat treatment: place the head blank body treated in step 3 together with the die under the condition of 180-200°C for heat treatment for 0.1-0.5h;

[0138] Step 5, Stamping again: pressing down the punch again to stamp the head body that has been heat-treated in Step 4;

[0139] Step 6, cooling treatment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com