Titanium fiber toughening cold heading die and preparation method thereof

A titanium fiber and cold heading technology is applied in the field of titanium fiber toughening cold heading mold and its preparation, which can solve the problem of high cost, improve the bonding force and interface structure, easily meet the process conditions, and achieve the effects of high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

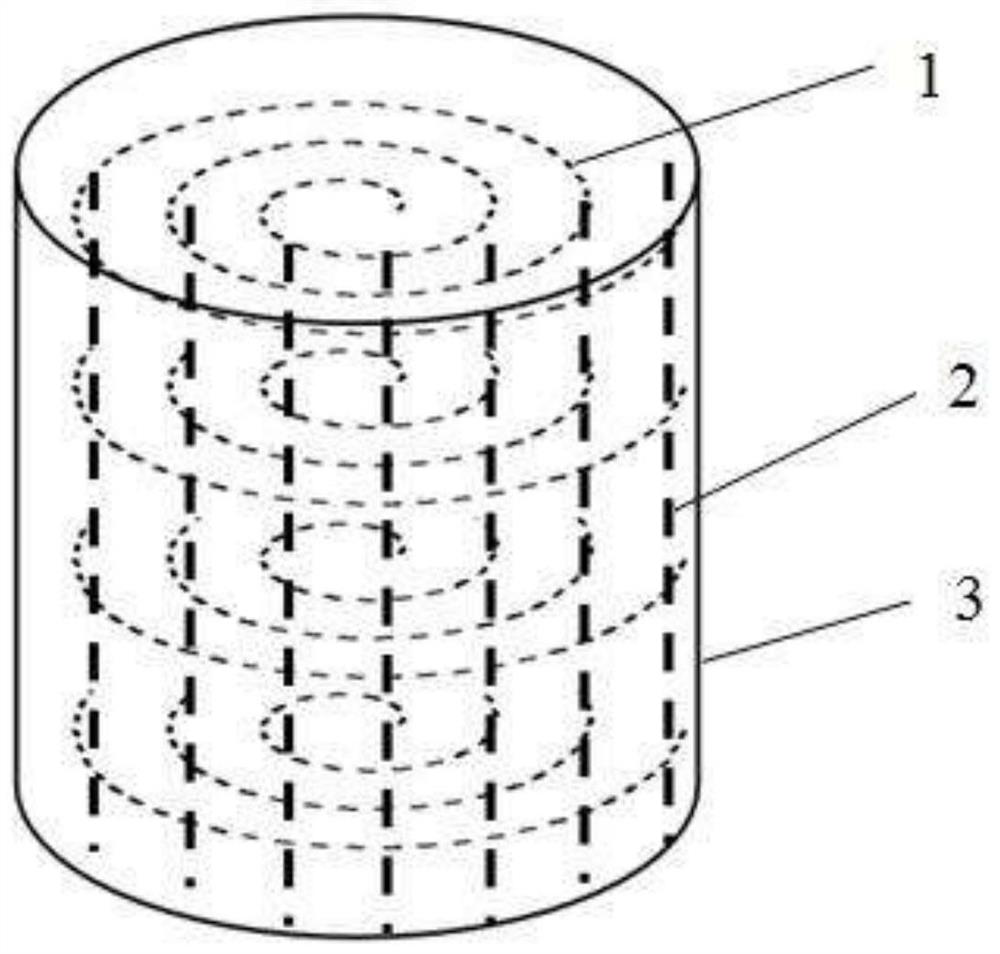

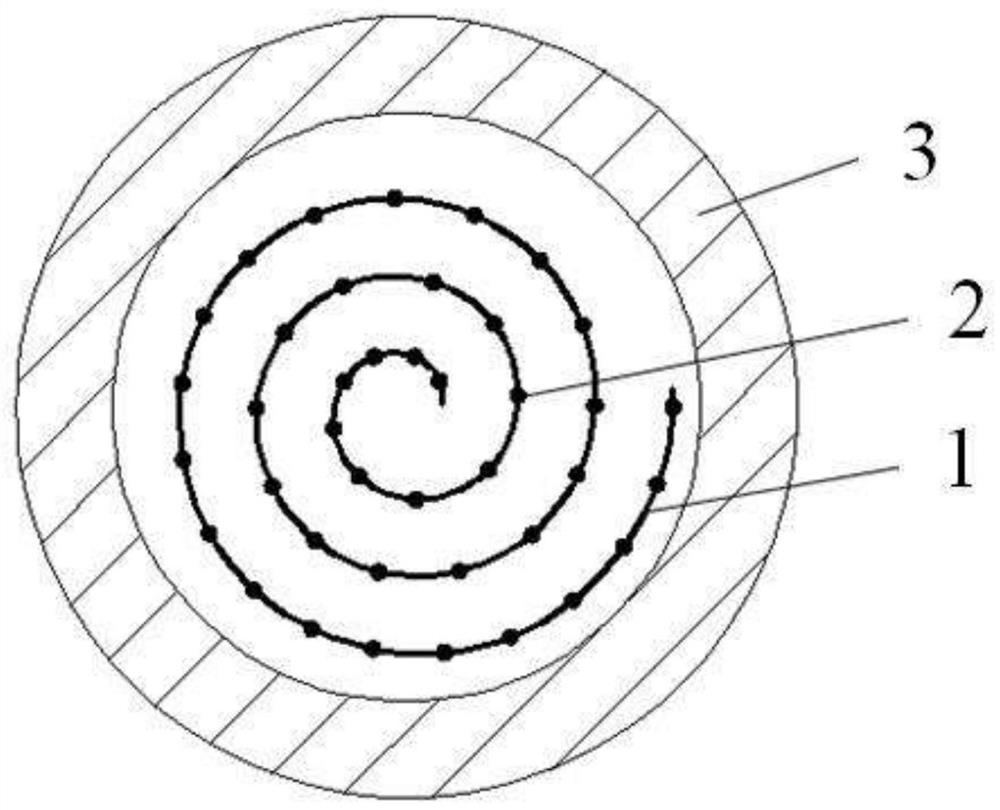

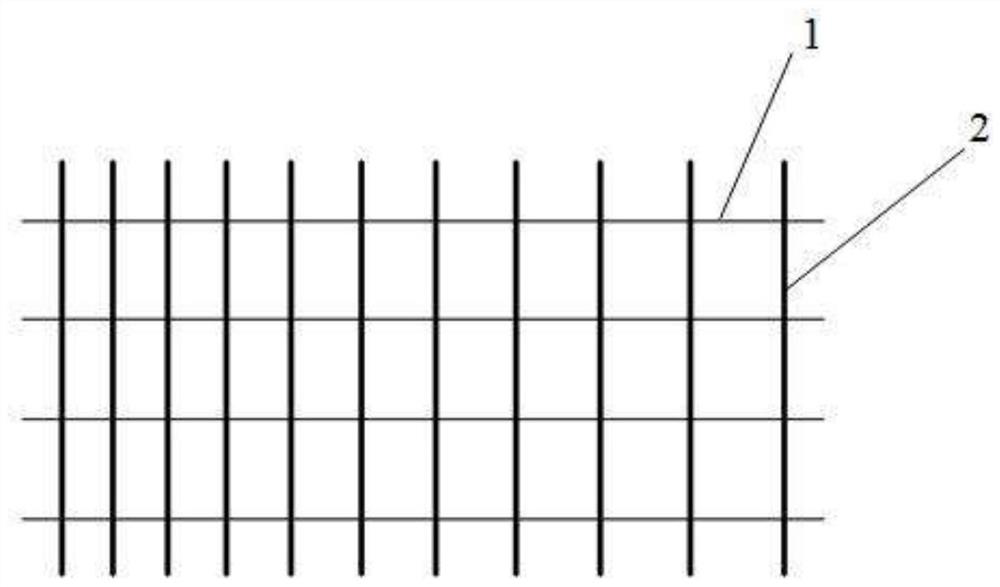

[0034] A kind of preparation method of titanium fiber toughening cold heading die of the present invention comprises the following steps:

[0035] Step 1, weigh the following components according to mass percentage, WC powder 70%-85%, Fe powder 5%-15%, Ti fiber 10%-20% and graphite powder 1%-3%, the above components The sum of the mass percentages is 100%; the particle size of the WC powder is 3 μm-10 μm, the particle size of the Fe powder is 8 μm-12 μm, and the diameter of the Ti fiber is 200 μm-1000 μm.

[0036]In step 2, use a ball mill to uniformly mix the WC powder, Fe powder and graphite powder weighed in step 1 to form a mixed powder. During the mixing process, the speed of the ball mill is 80-120r / min, and the ball milling time is 2h-10h. Add the mixed powder and binder into the kneader, the speed of the kneader is 30-50r / min, heat the solid mixed powder in the kneader, the heating temperature is 130°C-150°C, and the binder Wet the powder after heating and melting, an...

Embodiment 1

[0042] Prepare a kind of WC volume fraction and be the titanium fiber toughened cold heading die of 45%, comprise the following steps:

[0043] Step 1, weigh the following components according to mass percentage, WC powder 70.9%, Fe powder 7.9%, Ti fiber 19.3% and graphite powder 1.9%, the sum of the mass percentages of the above components is 100%; wherein, WC powder The particle size of Fe powder is about 8 μm, and the particle size of Fe powder is about 10 μm.

[0044] Step 2, use a ball mill to mix the WC powder, Fe powder and graphite powder weighed in step 1 evenly to form a mixed powder. During the mixing process, the ratio of grinding balls to powder is 2:1, and the ball mill speed is 120r / min. The time is 6h.

[0045] Add the mixed powder and binder into the kneader, start the kneader at a speed of 50r / min, heat the solid mixed powder in the kneader at a heating temperature of 140°C, and wait until the binder is heated Wet the powder after melting and fully wrap it ...

Embodiment 2

[0052] Prepare a kind of WC volume fraction and be that the titanium fiber toughening cold heading die of 47%, comprises the following steps:

[0053] Step 1, take the following components according to mass percentage, WC powder 72.2%, Fe powder 8.4%, Ti fiber 17.5% and graphite powder 1.9%, the sum of the mass percentages of the above components is 100%; wherein, WC powder The particle size of Fe powder is about 8 μm, and the particle size of Fe powder is about 10 μm.

[0054] Step 2, use a ball mill to mix the WC powder, Fe powder and graphite powder weighed in step 1 evenly to form a mixed powder. During the mixing process, the ratio of grinding balls to powder is 2:1, and the ball mill speed is 80r / min. The time is 4h.

[0055] Add the mixed powder and binder into the kneader, start the kneader at a speed of 40r / min, heat the solid mixed powder in the kneader at a heating temperature of 140°C, and wait until the binder is heated Wet the powder after melting and fully wra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com