Active biological filter material and sewage high-efficiency nitrogen and phosphorus removal method using the same

A technology of biological filter material and biological membrane method, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of low oxygen utilization rate, influence, poor phosphorus removal performance, etc. , to achieve the effect of improving overall efficiency, improving removal efficiency, and good bioaffinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation steps of the active biological filter material are as follows:

[0037] (1-1) Use calcium, silicon, aluminum inorganic mineral elements as the main raw materials, and conduct quantitative analysis of their chemical composition;

[0038] (1-2) Determine the ratio of raw materials according to the calcium-silicon-aluminum ternary phase diagram;

[0039] (1-3) Mix the raw materials evenly with a cement mortar mixer, control the water-solid ratio within the range of 0.02-0.1, and then make green balls through a centrifugal ball forming machine;

[0040] (1-4) Naturally cured the raw balls at room temperature for 24 hours, then dried them in a drying oven at 105°C for 12 hours, and finally put them into a high-temperature calciner for calcination at a heating rate of 5-10°C / min. Furnace cools.

[0041] The raw materials for the preparation of active biological filter materials are widely selected, the calcination temperature is 900-1100°C, and the particle ...

Embodiment 1

[0066] Select papermaking lime mud (50wt%) and fly ash (50wt%) as raw materials, adjust the water-solid ratio to 0.05 for stirring, and make green balls through a centrifugal ball forming machine, and dry the green balls at 105°C after natural curing for 48 hours , and then calcined at 1050°C and held for 2 h, and finally cooled in the furnace. The prepared active biological filter cartridge has a compressive strength of 7.0MPa, a 24h water absorption rate of 31.72%, and a porosity of 25.3%. The main phases are anorthite and anorthite.

Embodiment 2

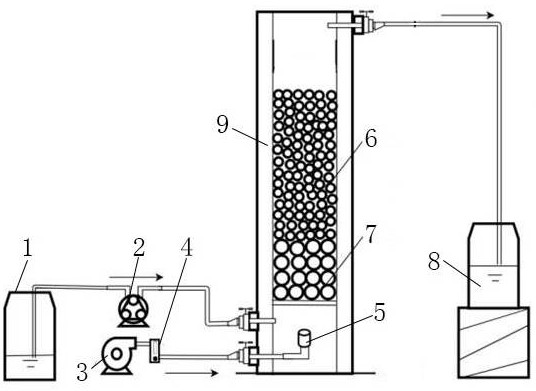

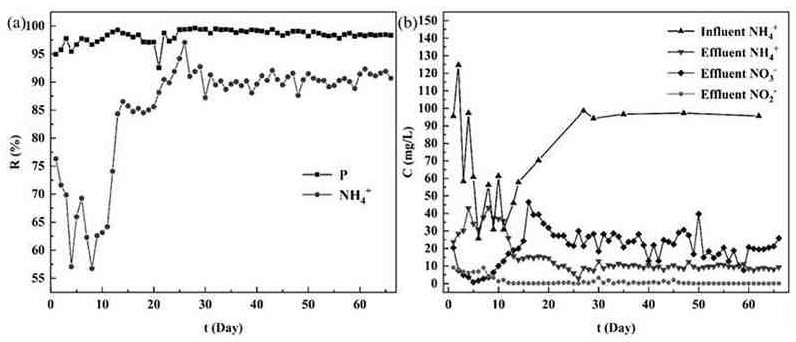

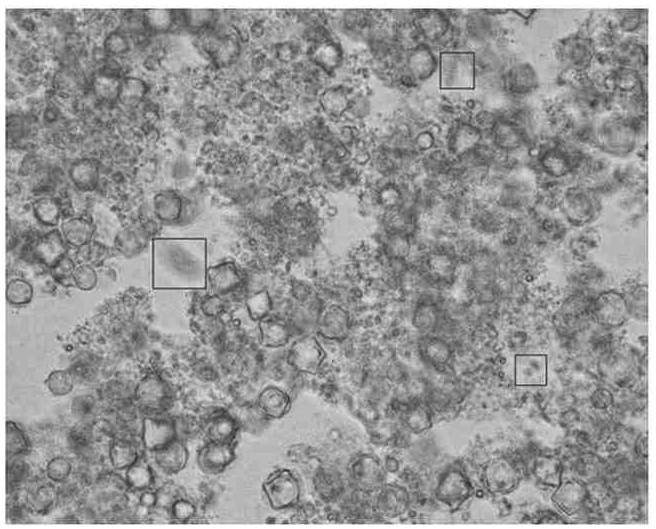

[0068] according to figure 1 As shown, the biofilm reactor was assembled. The biofilm reactor is a transparent double-layer plexiglass column with an inner diameter of 60mm and a height of 600mm, and the filling height of the filter material is 360mm. The bottom of the biofilm reactor is equipped with an aeration head and a water inlet pipe, and adopts an upward flow operation mode. When the biofilm reactor is started, the inoculation and film formation method is adopted, and the aerobic activated sludge is mixed with C 6 h 12 o 6 (500mg / L) and NH 4 Cl (100mg / L) solution was diluted, introduced into the reactor until the filter material was completely submerged, the air intake was adjusted to about 6L / h, and exposed for 2 days. The simulated sewage containing nitrogen and phosphorus (500mg / L C 6 h 12 o 6 , 100mg / L NH 4 Cl, 20mg / LKH 2 PO 4 , 200mg / L MgSO 4 ·7H 2 O, 10mL / L trace element solution SL-4), control the influent flow rate to 0.021L / h, the hydraulic retent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com