Method for improving denitrification efficiency of pig raising wastewater

A technology for denitrification efficiency and wastewater, applied in chemical instruments and methods, animal husbandry wastewater treatment, water pollutants, etc., can solve the problem of high cost of denitrification of pig wastewater, improve denitrification efficiency, and achieve considerable social and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1. After crushing the chaff and drying it naturally, add water to the anaerobic reactor at a solid-to-liquid ratio of 10% (v / v); after inoculation, adjust to pH 6 and ferment at room temperature for 20 days;

[0030] Step 2, after the fermentation is finished, remove the solid residue by vacuum filtration, and let the obtained liquid organic matter stand still at room temperature for 30 minutes, and after vacuum filtration again, seal it for later use at room temperature;

[0031] Step 3, adding the above-mentioned liquid organic matter into the SBR reactor for treating pig wastewater.

Embodiment 2

[0033] Step 1. After crushing the chaff and drying it naturally, add water to the anaerobic reactor at a solid-to-liquid ratio of 30% (v / v); after inoculation, adjust the pH to 8 and ferment at room temperature for 40 days;

[0034] Step 2. After the fermentation is finished, remove the solid residue by vacuum filtration, and place the obtained liquid organic matter at room temperature for 60 minutes. After vacuum filtration again, seal it for later use at room temperature;

[0035] Step 3, adding the above-mentioned liquid organic matter into the SBR reactor for treating pig wastewater.

Embodiment 3

[0037] Step 1. After crushing the fungus chaff and drying it naturally, add water to the anaerobic reactor at a solid-to-liquid ratio of 20% (v / v); after inoculation, adjust the pH to 7 and ferment at room temperature for 30 days;

[0038] Step 2. After the fermentation is finished, remove the solid residue by vacuum filtration, and let the obtained liquid organic matter stand still at room temperature for 45 minutes. After vacuum filtration again, seal it for later use at room temperature;

[0039] Step 3, adding the above-mentioned liquid organic matter into the SBR reactor for treating pig wastewater.

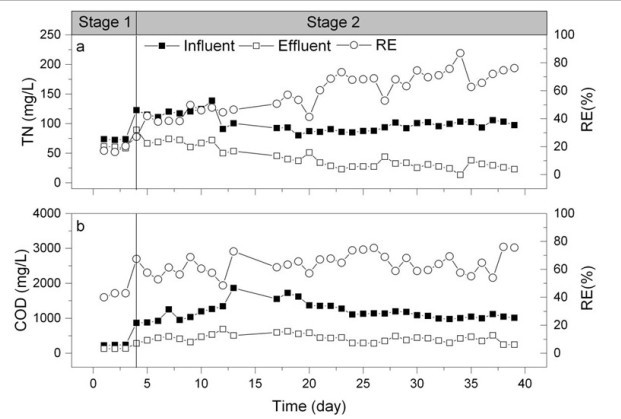

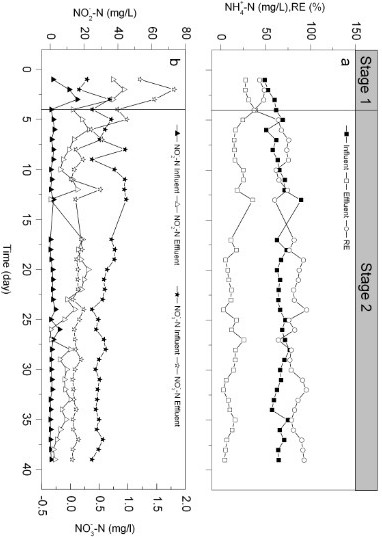

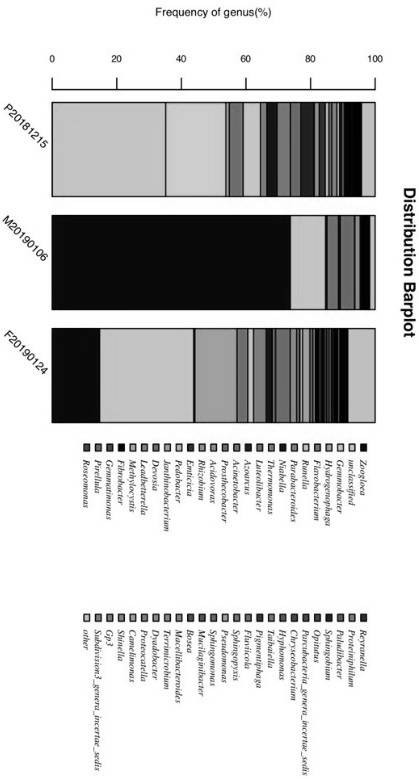

[0040] Table 1 and Table 2 are the trace elements and organic acid components contained in the anaerobic fermentation broth of fungus chaff respectively. From the perspective of trace elements, magnesium is an activator of many enzymes; iron is a cofactor of cytochrome cd1-type nitrite reductase; copper plays an important role in the process of building the active center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com