Moulded pipe processing system for metallurgy casting

A casting molding and processing system technology, used in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as affecting work, scratches, and cumbersome work, and achieve work efficiency, speed, and pipe waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

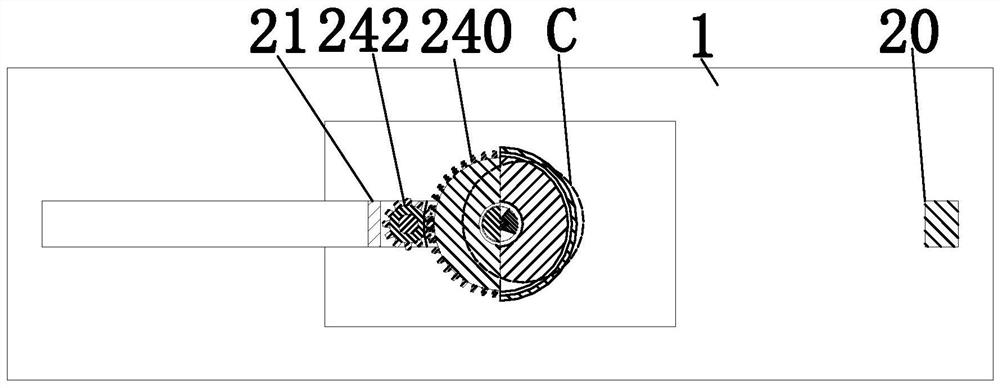

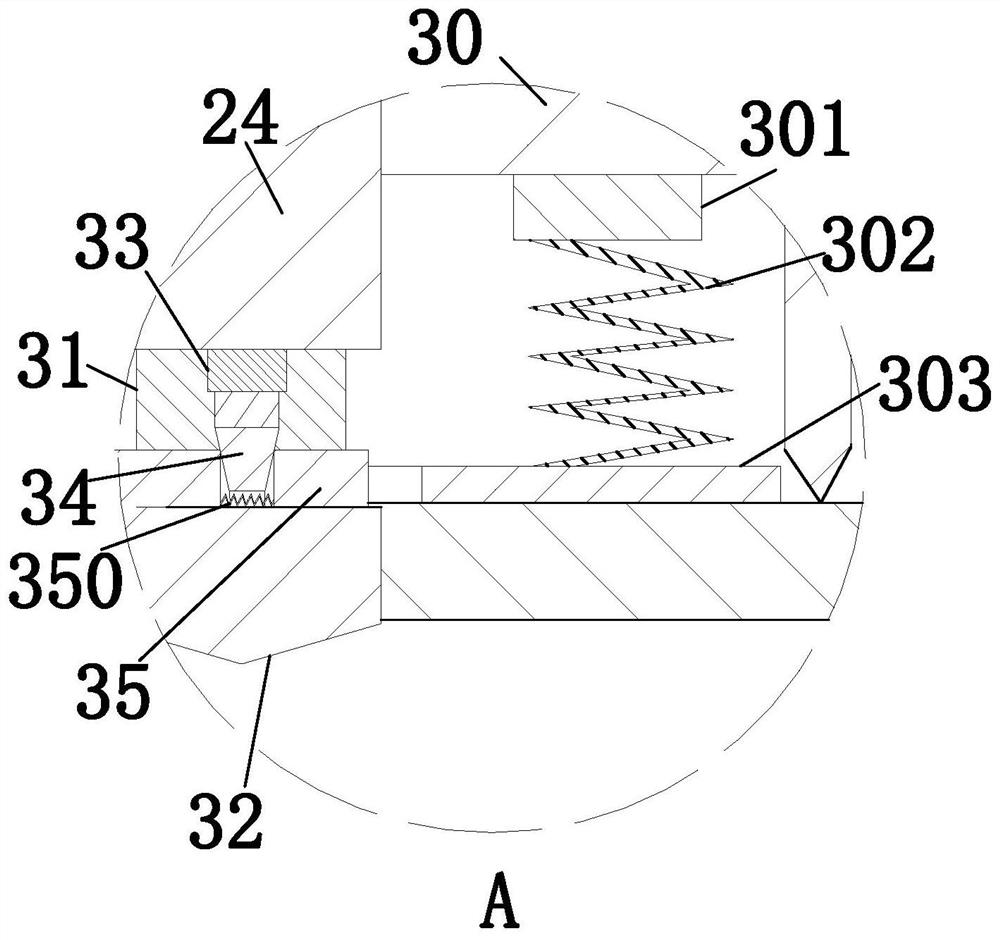

[0026] Such as Figure 1 to Figure 5 As shown, a metallurgical casting forming pipe processing system includes a workbench 1, a support mechanism 2 and a waste clamping mechanism 3. The workbench 1 is installed on the existing working ground, and the upper end of the workbench 1 is installed with The supporting mechanism 2 is provided with a scrap clamping mechanism 3 in the middle of the supporting mechanism 2 .

[0027] The support mechanism 2 includes an inverted L-shaped plate 20, a support plate 21, a rectangular baffle plate 22, a boss 23 and a drill rod 24, and the inverted L-shaped plate 20 is symmetrically installed on the upper end surface of the workbench 1. The upper end surface of the L-shaped plate 20 is equipped with a support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com