Preparation and analysis method of X-ray fluorescent fuse piece for determining molybdenum content in molybdenum oxide

A technology of molybdenum oxide and content, which is applied in measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve problems such as inaccurate analysis results, reduce environmental pollution, save resources and energy, and use less chemical reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Select 5 internal standard samples and try to select the production coverage. Weigh 0.2000g of molybdenum oxide (molybdenum oxide ball) and 0.2000g of calcium oxide, then weigh 1.0000g of lithium nitrate and 1.0000g of sodium carbonate-free, put them into a porcelain crucible, and stir evenly. Weigh 8.0000g of lithium tetraborate flux and 0.200g of ammonium iodide release agent into a platinum crucible, stir evenly with a plastic stirring rod, and slowly pour the evenly mixed porcelain crucible reagents into a platinum crucible with the reagents upside down.

[0037] Select the melting curve of molybdenum oxide (molybdenum oxide ball) on the electric melting furnace, place the above-mentioned platinum crucible with reagents on the electric melting furnace, click the confirm and start button, and make a uniform and transparent glass sheet in about 17 minutes .

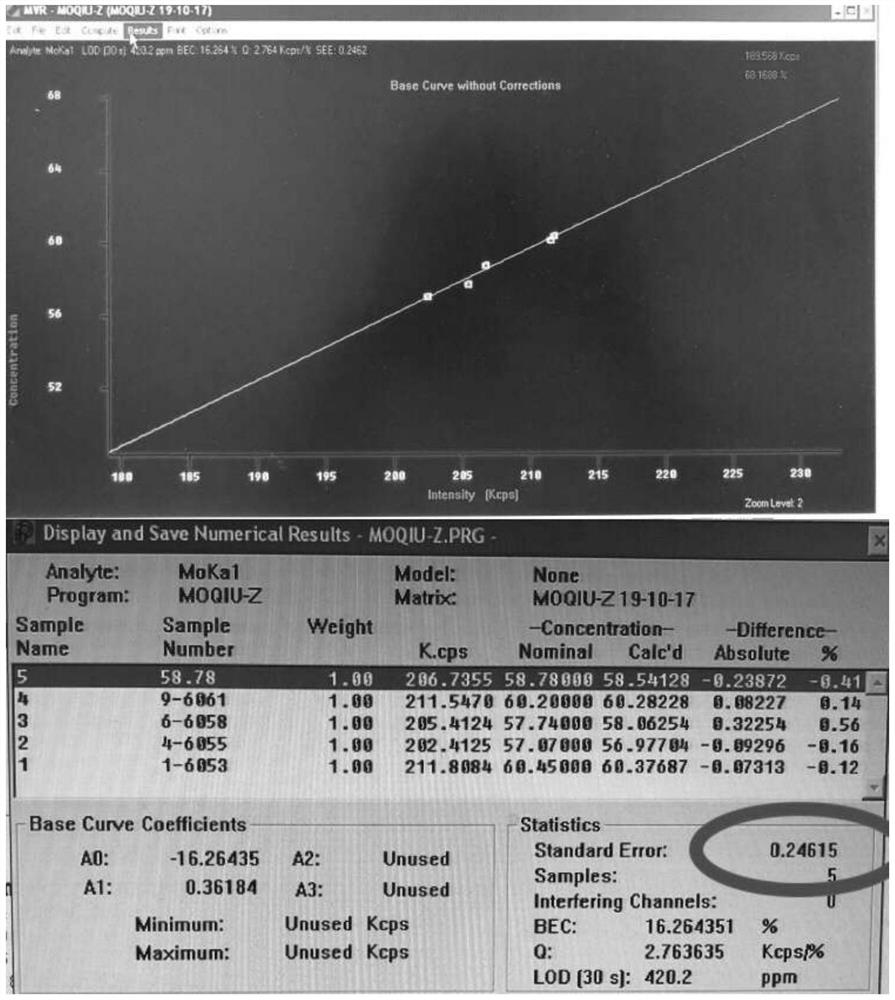

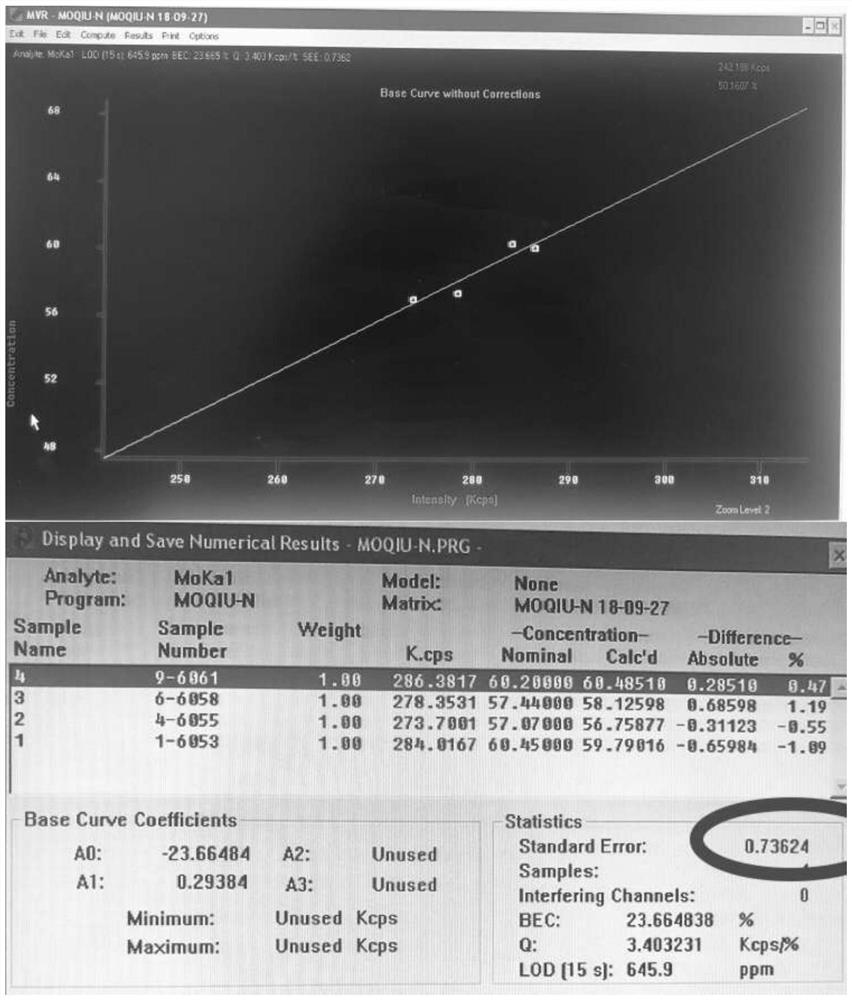

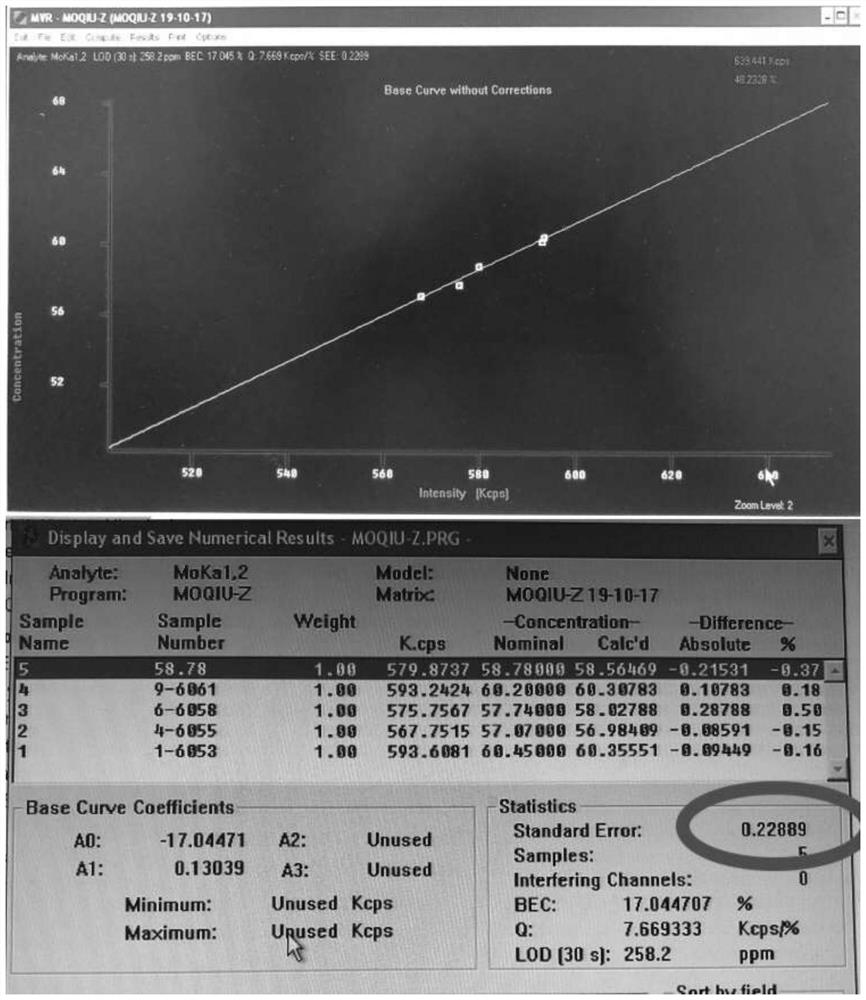

[0038] According to the establishment steps of the working curve of the X-ray fluorescence spectrometer, sele...

Embodiment 2

[0040] Weigh 0.2000g of molybdenum oxide (molybdenum oxide ball) and 0.2000g of calcium oxide, then weigh 1.0000g of lithium nitrate and 1.0000g of sodium carbonate-free, put them into a porcelain crucible, and stir evenly. Weigh 8.0000g of lithium tetraborate flux and 0.200g of ammonium iodide release agent into a platinum crucible, stir evenly with a plastic stirring rod, slowly pour the uniformly mixed porcelain crucible reagent into a platinum crucible containing the reagent,

[0041] Table 1 Internal standard content and number

[0042] serial number name serial number Mo content / % 1 Molybdenum Oxide / Molybdenum Oxide Balls 58.78 55.78 2 Molybdenum Oxide / Molybdenum Oxide Balls 9-6061 60.20 3 Molybdenum Oxide / Molybdenum Oxide Balls 6-6058 57.74 4 Molybdenum Oxide / Molybdenum Oxide Balls 4-6055 57.07 5 Molybdenum Oxide / Molybdenum Oxide Balls 1-6053 60.45

[0043] The procedure for setting the electric melting furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com