Polyarylether-based polymer with polyethylene glycol structure as side chain, solid polymer electrolyte and preparation method thereof

A solid polymer, polyethylene glycol technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, electrolyte immobilization/gelation, etc., can solve the problem of not being able to meet the conditions of use at the same time, achieve good ionic conductivity, improve electrical conductivity The effect of lower rate, guaranteeing mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

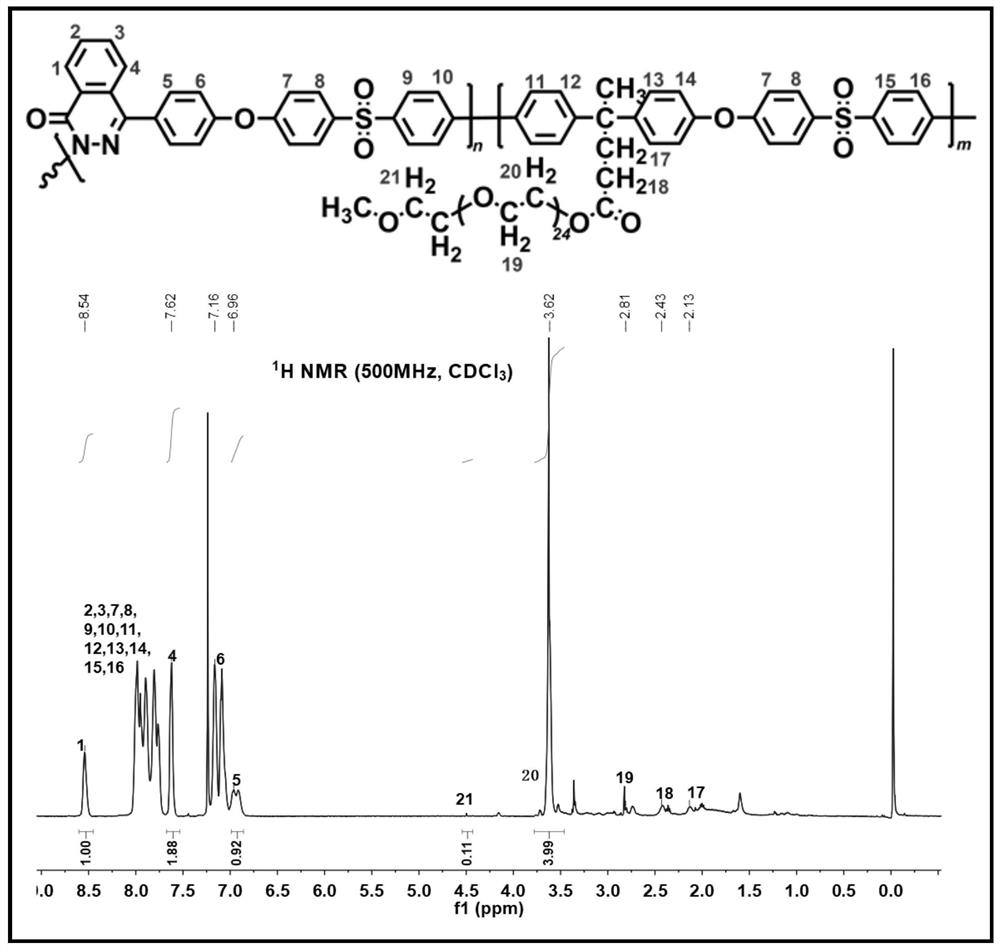

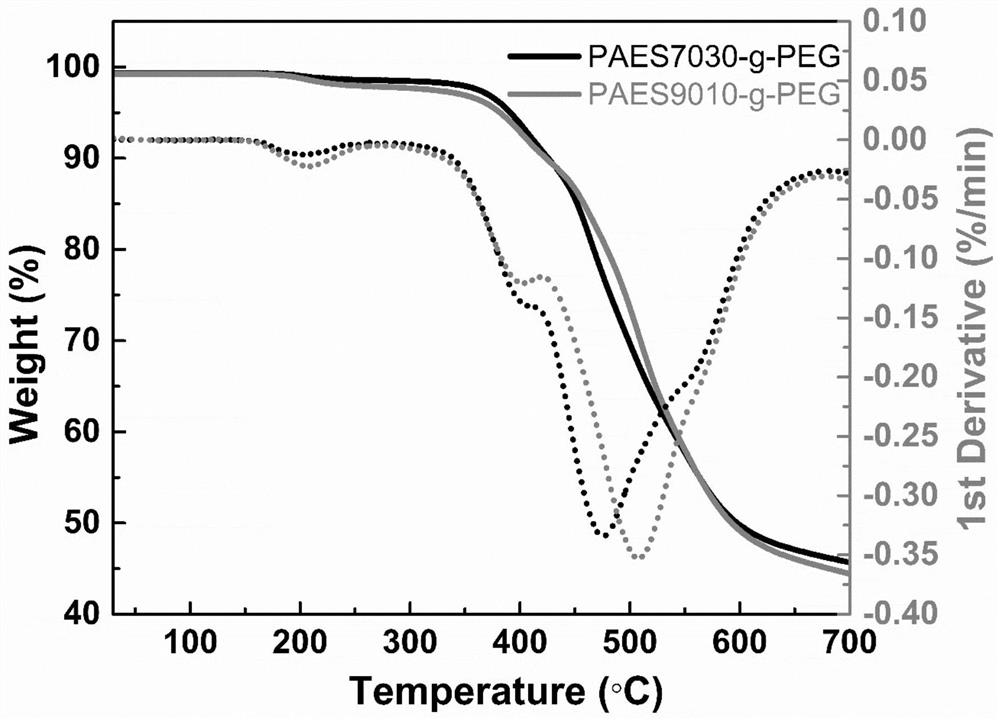

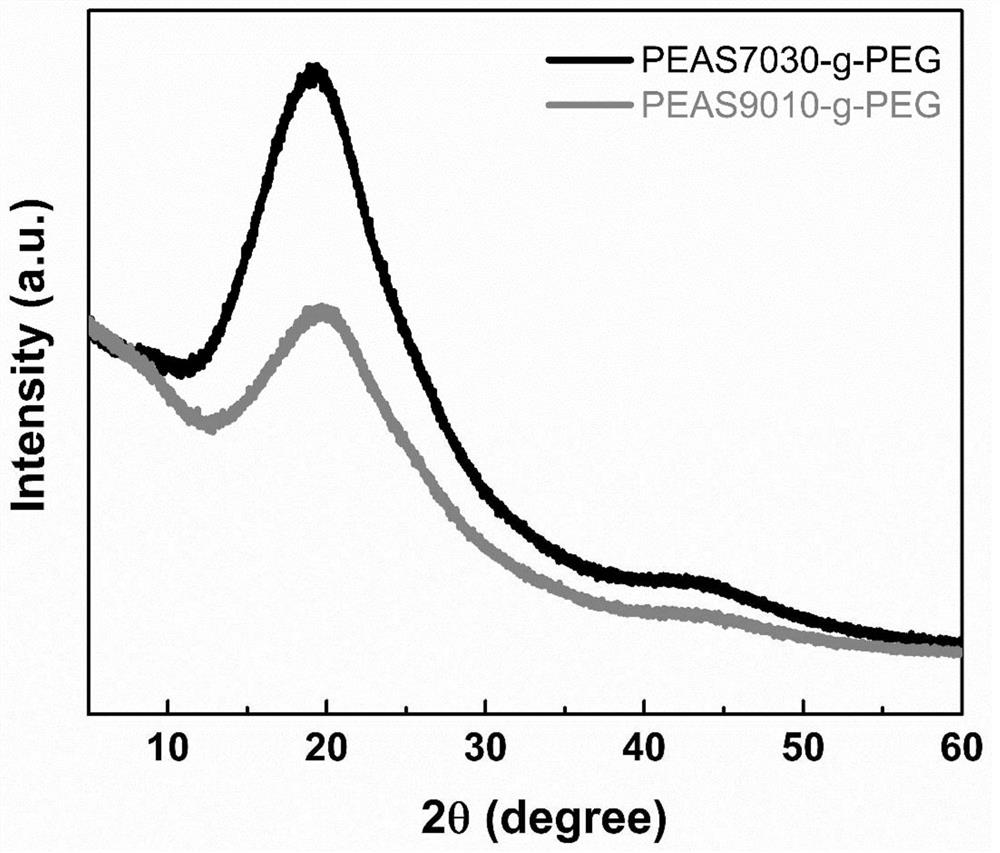

[0050] Preparation of Example 1 Polyethylene Glycol 1000 Grafted Polyarylene Ether-Based Polymer PAES7030-g-PEG

[0051] 1) In 100 mL of sulfolane solvent with a concentration of 98%, add 0.07 mol, 0.1 mol and 0.03 mol of phenol monomers with phthalazinone structure, 4,4'-difluorodiphenyl sulfone, bisphenolic acid and 4g potassium carbonate. Then add 50mL of water-carrying agent toluene, the reactant is fully stirred and dissolved, and then heated to 130°C and refluxed for 4 hours to ensure that the water generated by the salt-forming reaction is completely removed, and then the toluene is removed, and finally the system is heated to 180°C for 6 hours. , to obtain a polymer solution.

[0052] 2) Pour the polymer solution prepared above into deionized water to precipitate, and obtain flexible polymer thin strips, which are washed 3 times with deionized water to remove residual reaction solvents and small molecular substances that do not participate in the reaction; the product...

Embodiment 2

[0058] Example 2 Preparation of polyethylene glycol 1000 grafted polyarylether-based polymer PAES9010-g-PEG

[0059] 1) In 100 mL of sulfolane solvent with a concentration of 98%, add 0.09 mol, 0.1 mol and 0.01 mol of phenol monomers with phthalazinone structure, 4,4'-difluorodiphenyl sulfone, bisphenolic acid and 4g potassium carbonate. Then add 50mL of water-carrying agent toluene, the reactant is fully stirred and dissolved, and then heated to 130°C and refluxed for 4 hours to ensure that the water generated by the salt-forming reaction is completely removed, and then the toluene is removed, and finally the system is heated to 180°C for 6 hours. , to obtain a polymer solution.

[0060] 2) Pour the polymer solution prepared above into deionized water to precipitate, and obtain flexible polymer thin strips, which are washed 3 times with deionized water to remove residual reaction solvents and small molecular substances that do not participate in the reaction; the product is ...

Embodiment 3

[0071] Example 3: Preparation of solid polymer electrolytes 1 and 2 by solvent evaporation

[0072] 1) 0.8 g of the dry polyarylether-based polymers containing polyethylene glycol structure in the side chain prepared in Example 1 and Example 2 were respectively dissolved in 8 mL of solvent sulfolane, and stirred at room temperature for 7 h to obtain a uniform, Transparent mixed solution.

[0073] 2) Pour the solution prepared in step 1) onto a horizontal glass plate of 8×8cm to form a film, and dry it in vacuum at 30-60°C for 72 hours to remove the solvent to obtain a polymer solid electrolyte membrane, and then immerse the polymer solid electrolyte membrane in In a lithium salt solution with a concentration of 10 wt%, the membranes were taken out to obtain all-solid polymer electrolytes 1 and 2, respectively. Wherein, the tensile strength of the obtained polymer solid electrolyte membrane is 40MPa and 35MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com