Anti-infection and anti-coagulation coating for central venous catheter and preparation method of anti-infection and anti-coagulation coating

A central venous catheter, anti-infection technology, applied in anti-coagulation treatment, catheter, coating and other directions, can solve the problems of poor antibacterial effect, cumbersome process operation steps, poor anti-infection effect, etc., and achieves improved smoothness and simple process. , easy to obtain the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

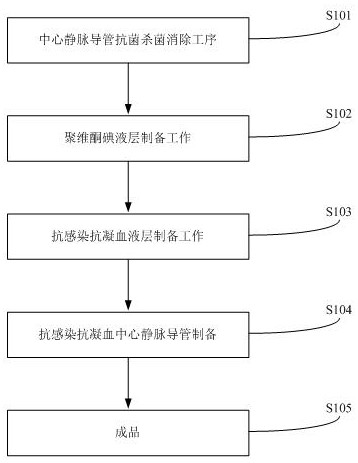

[0042] as attached figure 1 shown

[0043] An anti-infection and anti-coagulant coating for a central venous catheter comprises the following raw materials in parts by weight: 0.1-1% polyvinylpyrrolidone, 0.2-2% minocycline hydrochloride, 0.7-1% KH560 silane coupling agent, poly Vitamin iodine 2-3%, medical disinfectant 90-93%.

[0044] Preferably, the povidone-iodine is a complex product composed of polyvinylpyrrolidone and iodine.

[0045] A preparation method for an anti-infection anti-coagulation coating for a central venous catheter comprises the following steps:

[0046] S101: Central venous catheter antibacterial sterilization and elimination process, take out the central venous catheter, rinse it with medical disinfectant water, dry it in the air, and then sterilize it in an antibacterial sterilization box, and heat it by heating to remove the central venous catheter The excess residual liquid on the surface of the venous catheter is stored in a stainless steel box ...

specific Embodiment 1

[0070] An anti-infection and anti-coagulation coating for a central venous catheter comprises the following raw materials in parts by weight: 0.1% polyvinylpyrrolidone, 0.2% minocycline hydrochloride, 0.7% KH560 silane coupling agent, 2% povidone-iodine, 90% medical disinfectant.

[0071] A preparation method for an anti-infection anti-coagulation coating for a central venous catheter comprises the following steps:

[0072] Step 1: Central venous catheter antibacterial sterilization and elimination process, take out the central venous catheter, rinse it with medical disinfectant water, dry it in the air, and then perform sterilization and sterilization work through an antibacterial sterilization box, and heat it by heating to remove The excess residual fluid on the surface of the central venous catheter is stored in a stainless steel box at normal temperature and pressure, for use;

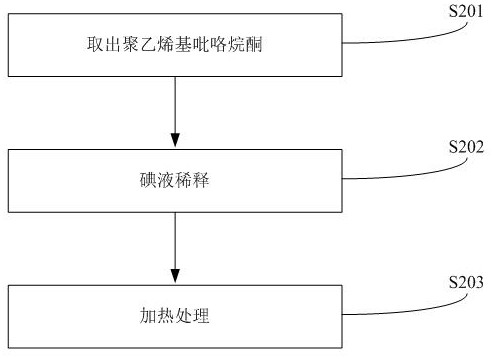

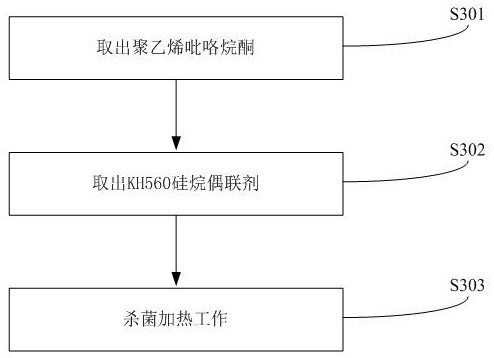

[0073] Step 2: Preparation of povidone-iodine liquid layer, the specific operation should be ...

specific Embodiment 2

[0086] An anti-infection and anti-coagulation coating for a central venous catheter comprises the following raw materials in parts by weight: 1% polyvinylpyrrolidone, 2% minocycline hydrochloride, 1% KH560 silane coupling agent, 3% povidone-iodine, 93% medical disinfectant.

[0087] A preparation method for an anti-infection anti-coagulation coating for a central venous catheter comprises the following steps:

[0088] Step 1: Central venous catheter antibacterial sterilization and elimination process, take out the central venous catheter, rinse it with medical disinfectant water, dry it in the air, and then perform sterilization and sterilization work through an antibacterial sterilization box, and heat it by heating to remove The excess residual fluid on the surface of the central venous catheter is stored in a stainless steel box at normal temperature and pressure, for use;

[0089] Step 2: Preparation of povidone-iodine liquid layer, the specific operation should be carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com