Cmp compositions for sti applications

A polishing composition, chemical mechanical technology, applied in the direction of polishing composition containing abrasives, other chemical processes, chemical instruments and methods, etc., can solve problems such as SiN loss, erosion, and influence on device manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] (1) The chemical mechanical polishing composition shown in embodiment (1), comprising: (a) ceria (ceria) abrasive particles; (b) cationic polymer; (c) nonionic polymer comprising polyethylene Glycol Stearyl Ether, Polyethylene Glycol Lauryl Ether, Polyethylene Glycol Oleyl Ether, Poly(ethylene)-co-poly(ethylene glycol), Octylphenoxypoly(ethyleneoxy) Ethanol, or a combination thereof; (d) a saturated monobasic acid; and (e) an aqueous carrier.

[0064] (2) Embodiment (2) shows the polishing composition of embodiment (1), wherein the ceria abrasive particles include calcined ceria particles, wet ceria particles, wet-based Wet-based processed ceria particles, or combinations thereof.

[0065] (3) Embodiment (3) shows the polishing composition of embodiment (1) or (2), wherein the cerium oxide abrasive particles are present in the polishing composition at a concentration of about 0.0005% by weight to about 10% by weight.

[0066] (4) The polishing composition of any one o...

Embodiment 1

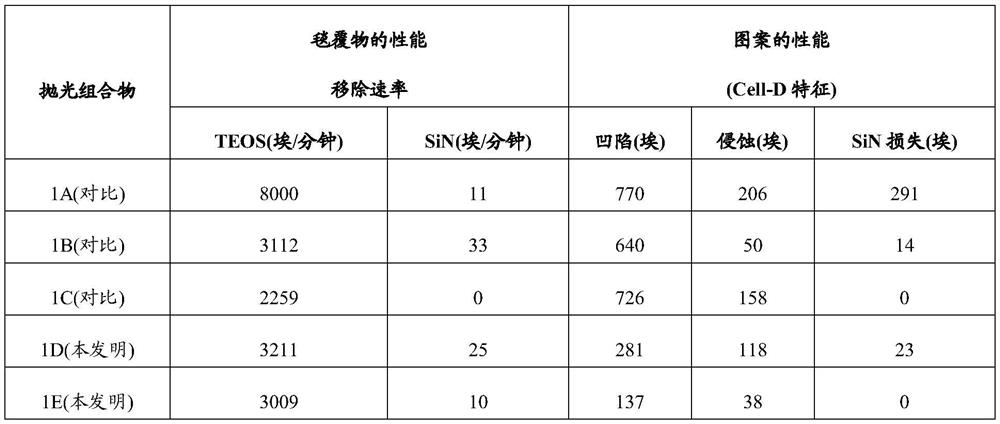

[0105] This example demonstrates the effectiveness of a chemical mechanical polishing composition comprising: ceria abrasive particles, a cationic polymer, a nonionic polymer comprising polyethylene glycol stearyl ether, saturated Monobasic acid, and aqueous carrier. This example also demonstrates a method for chemical mechanical polishing of a substrate according to an embodiment of the present invention.

[0106] Individual substrates each comprising a dielectric layer on the substrate surface and a silicon nitride (SiN) layer (0.18×0.18 μm pattern size) on the substrate surface were polished with five different polishing compositions 1A to 1E ( Cell D feature), so as to evaluate the polishing performance of the blanket (blanket) and the polishing performance of the pattern. Use IC1010 TM Pad or NEXPLANAR TM E6088 pad, on REFLEXION with 300mm platform TM Polish the substrate on the polishing tool.

[0107]Polishing Composition 1A (comparative) contained 0.29% by weight ...

Embodiment 2

[0116] This example demonstrates the effectiveness of a chemical mechanical polishing composition comprising: cerium oxide abrasive particles, a cationic polymer, a nonionic polymer comprising polyethylene glycol stearyl ether, a saturated monobasic acid, and aqueous carriers. This example also demonstrates a method for chemical mechanical polishing of a substrate according to an embodiment of the present invention.

[0117] The blanket was evaluated by polishing separate substrates, each comprising a dielectric layer on the substrate surface and a silicon nitride (SiN) layer on the substrate surface (Cell D feature), with two different polishing compositions 2A and 2B. Overlay polishing performance and pattern polishing performance. Each substrate was overpolished to approximately The endpoint (endpoint).

[0118] Polishing Composition 2A (comparative) contained 0.20% by weight of cerium oxide abrasive particles and 0.0065% by weight of 3,5-dihydroxybenzoic acid as a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com