Ultraviolet LED high-counter electrode, ultraviolet LED and preparation method thereof

A high-reflection, electrode technology, applied in the field of electrodes, can solve the problems of inapplicability for large-scale industrial production, low band gap, difficult processing, etc., and achieve the effect of improving photon extraction efficiency, good ohmic contact performance, and reducing contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

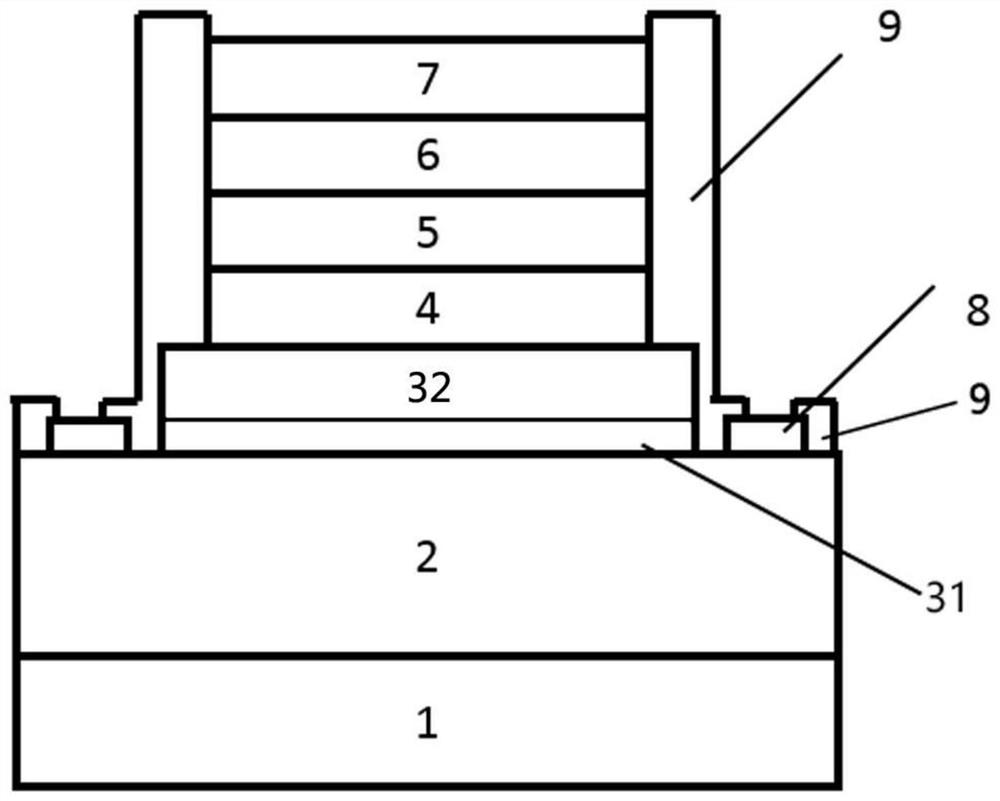

Embodiment 1

[0049] (1) Epitaxial growth of ultraviolet LED epitaxial film on sapphire substrate 1 based on metal organic chemical vapor deposition (MOCVD) (n-type semiconductor layer 2 is n-type AlGaN, p-type semiconductor layer 32 is p-type GaN, in n-type semiconductor layer 2 and the p-type semiconductor layer 32 with the active layer 31 as the light emitting layer), the growth temperature is 1200° C., the gas pressure is 50 torr, and the light emission wavelength is 275 nm to form Mg-doped AlGaN and GaN layers. The hole concentration of Mg-doped GaN is 5× 10 17 cm -3 ; (When using a sapphire substrate, because the sapphire itself is transparent, the substrate may not be peeled off; when silicon and silicon carbide are used as the substrate, it is not transparent, so the substrate needs to be peeled off)

[0050] (2) Preparation of UV LED mesa based on plasma etching, using Cl 2 / BCl 3 Plasma, the flow rate is 50 / 10sccm, the mesa width is 500×500μm 2 ;

[0051] (3) Deposition of 10...

Embodiment 2

[0055](1) Epitaxial growth of ultraviolet LED epitaxial film on sapphire substrate based on metal organic chemical vapor deposition (MOCVD) (n-type semiconductor layer 2 is n-type GaN, p-type semiconductor layer 32 is p-type GaN, in n-type semiconductor layer 2 and the p-type semiconductor layer 32 with the active layer 31 as the light emitting layer), the growth temperature is 1100°C, the gas pressure is 20 torr, and the light emission wavelength is 300nm to form a Mg-doped GaN layer with a hole concentration of 5×10 17 cm -3 ;

[0056] (2) Preparation of UV LED mesa based on plasma etching, using Cl 2 / BCl 3 Plasma, the flow rate is 50 / 10sccm, the mesa width is 300×300μm 2 ;

[0057] (3) Deposition of 50nm Al based on ALD 2 o 3 Passivation layer 9, using trimethylaluminum and H 2 O is used as the source of aluminum and oxygen, and the deposition temperature is 400 °C; and holes are opened on the n-GaN layer by photolithography and wet etching processes, and the deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com