Organic-inorganic nano hybrid waterborne high-temperature-resistant anticorrosive coating and preparation method thereof

A technology of inorganic nano and anti-corrosion coatings, which is applied in anti-corrosion coatings, fire-proof coatings, polyurea/polyurethane coatings, etc., and can solve the problems of high-temperature resistance and insufficient anti-corrosion performance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

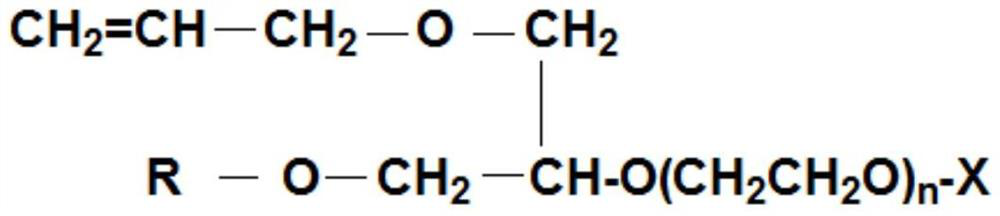

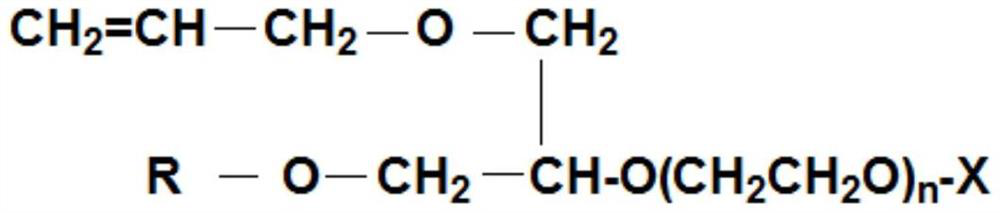

Method used

Image

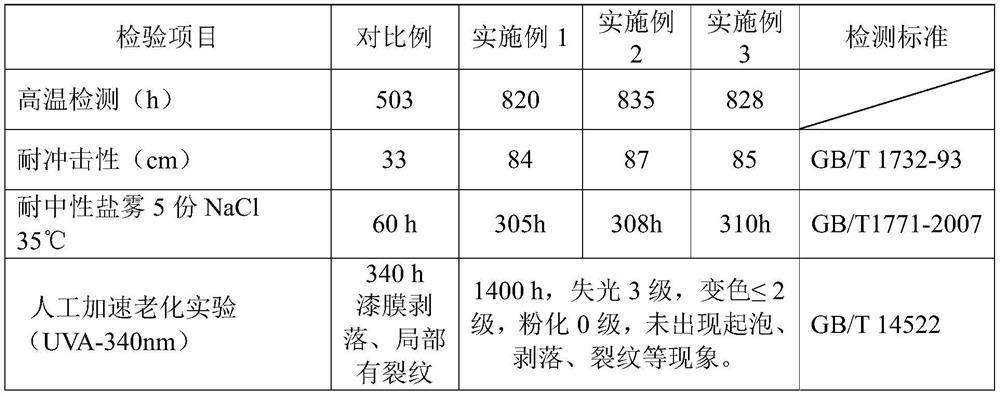

Examples

Embodiment 1

[0049] An organic-inorganic nano-hybrid water-based high-temperature anti-corrosion coating, including A component and B component used together, wherein A component includes the following components by weight:

[0050] 25 parts of deionized water, 0.5 part of wetting and dispersing agent Dispers 757W, 0.05 part of defoamer BYK011, 5 parts of nano filler, 30 parts of calcium boride, 50 parts of organic-inorganic nano hybrid high temperature resistant emulsion, 0.1 part of ammonia water, Variable aid Hemings 2990.5 parts;

[0051] B component comprises the component of following parts by weight:

[0052] 60 parts of water-based isocyanate curing agent, and 20 parts of PMA.

[0053] Wherein, the preparation method of organic-inorganic nano hybrid high temperature resistant emulsion is:

[0054] (1) Preparation of modified nano-silica

[0055] a. Mix silane coupling agent KH570 and MMA at a ratio of 1:1, slowly drop into the silica powder stirred at room temperature at high spee...

Embodiment 2

[0073] An organic-inorganic nano-hybrid water-based high-temperature anti-corrosion coating, including A component and B component used together, wherein A component includes the following components by weight:

[0074] 15 parts of deionized water, 0.8 part of wetting and dispersing agent Dispers 757W, 0.1 part of defoamer BYK011, 20 parts of nano filler, 5 parts of boron carbide, 60 parts of organic-inorganic nano hybrid high temperature resistant emulsion, 0.2 part of ammonia water, rheology Auxiliary Hemings 2990.8 parts;

[0075] B component comprises the component of following parts by weight:

[0076] 80 parts of water-based isocyanate curing agent, and 40 parts of PGDA.

[0077] Wherein, the preparation method of organic-inorganic nano hybrid high temperature resistant emulsion is:

[0078] (1) Preparation of modified nano-silica

[0079] a. Mix the silane coupling agent KH570 and MMA at a ratio of 1:2, slowly drop into the silica powder stirred at room temperature a...

Embodiment 3

[0097] An organic-inorganic nano-hybrid water-based high-temperature anti-corrosion coating, including A component and B component used together, wherein A component includes the following components by weight:

[0098] 20 parts of deionized water, 0.6 part of wetting and dispersing agent Dispers 757W, 0.1 part of defoamer BYK011, 15 parts of nano filler, 40 parts of calcium boride, 55 parts of organic-inorganic nano hybrid high temperature resistant emulsion, 0.2 part of ammonia water, fluid Variable aid Hemings 2990.7 parts;

[0099] B component comprises the component of following parts by weight:

[0100] 60 parts of water-based isocyanate curing agent, and 20 parts of PMA.

[0101] Wherein, the preparation method of organic-inorganic nano hybrid high temperature resistant emulsion is:

[0102] (1) Preparation of modified nano-silica

[0103] a. Mix silane coupling agent KH570 and MMA at a ratio of 1:2, slowly drop into the silica powder stirred at room temperature at h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com