Ethylene oligomerization catalyst and preparation method and application thereof

A technology of ethylene oligomerization and catalyst, which is applied in the direction of catalysts, catalytic reactions, carbon compound catalysts, etc., can solve the problems of wide product distribution, easy blockage of pipelines, and high production costs, and achieve low polymer production, reduced dosage, and improved durability. The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

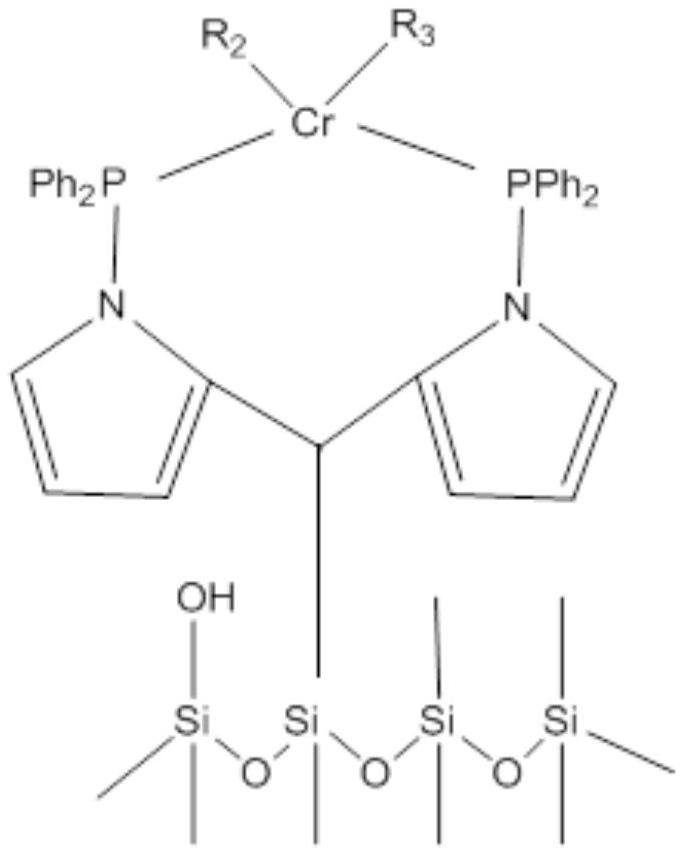

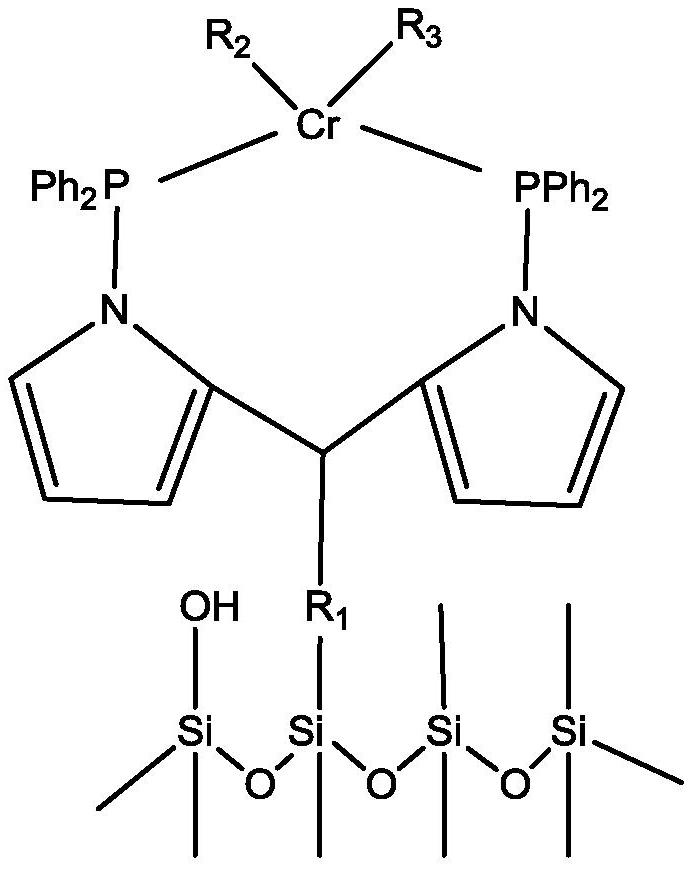

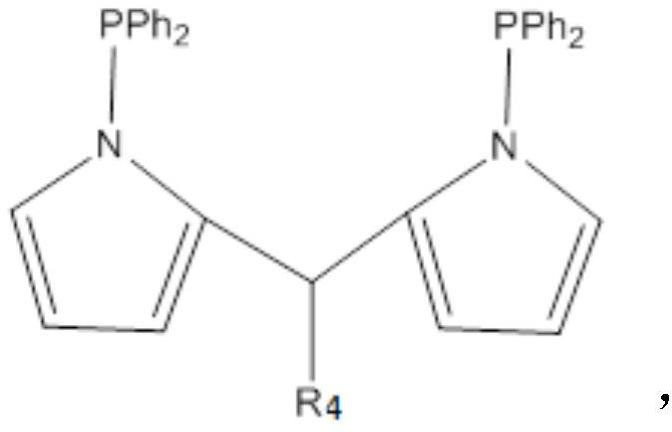

[0035] Preparation of Ligand I: Weigh quantitative 1mol of pyrrole and 1mol of 2-pyrrole acetaldehyde, add to 150ml of pentane solution, slowly add 0.2mol of phosphorus oxychloride, react for 3 to 5 hours and filter to obtain insoluble pentane solution The dipyrrole cation salt, the ionic salt is dissolved in the pentane solution of the calcium hydroxide suspension, and shaken vigorously for 3-15 minutes to obtain the pentane solution of the dipyrromethene. At -78°C, add an excess of 3 mol n-butyl lithium dropwise to the dipyrromethene pentane solution, slowly warm up to room temperature, stir for 3 to 6 hours, filter and slowly add 2.5 mol n-butyl lithium dropwise to the solution at -75°C Chlorophenylphosphine, stirred for 3-5 hours, stirred overnight at room temperature, purified by neutral alumina column chromatography, and recrystallized twice to obtain the ligand I product. The Ligand I structure is shown below:

[0036]

[0037] Ligand grafting on silica gel: All opera...

Embodiment 2

[0042] Preparation of ligand: same as Example 1.

[0043] Ligand grafting on silica gel: Same as Example 1.

[0044] Loading active component Cr: Same as Example 1.

[0045] Ethylene oligomerization: Heat a 500ml reactor to 120°C, vacuumize for 4 hours, replace nitrogen three times during this period, then vacuumize and fill hydrogen twice, wait for the temperature to cool to room temperature, add 200ml of refined methylcyclohexane, 1.0 ml MAO (10wt% toluene solution), turn on the stirrer, after the temperature is constant at 80°C, add 0.4g catalyst, pass in hydrogen at 0.5Mpa, pass in ethylene to 4.5MPa for oligomerization reaction, after 30min of reaction, turn off the ethylene The inlet valve is used to quickly cool down with a low-temperature circulating water bath, slowly release the pressure, and unload the kettle to obtain ethylene oligomerization products.

Embodiment 3

[0047] Preparation of ligand: same as Example 1.

[0048] Ligand grafting on silica gel: Same as Example 1.

[0049] Loading active component Cr: Same as Example 1.

[0050] Ethylene oligomerization: Heat a 500ml reactor to 120°C, vacuumize for 4 hours, replace nitrogen three times during this period, then vacuumize and fill hydrogen twice, wait for the temperature to cool to room temperature, add 200ml of refined methylcyclohexane, 1.34 ml MAO (10wt% toluene solution), turn on the stirrer, after the temperature is constant at 80°C, add 0.4g catalyst, pass in hydrogen at 0.5Mpa, pass in ethylene to 4.5MPa for oligomerization reaction, after 30min of reaction, turn off the ethylene The inlet valve is used to quickly cool down with a low-temperature circulating water bath, slowly release the pressure, and unload the kettle to obtain ethylene oligomerization products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com