Probiotic stachyose and preparation process thereof

A preparation process, the technology of stachyose, applied in the field of probiotic stachyose and its preparation, can solve the problems of insufficient ability of stachyose to enhance the immune effect, so as to improve the body's disease resistance, promote fat metabolism, and promote brain health. The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

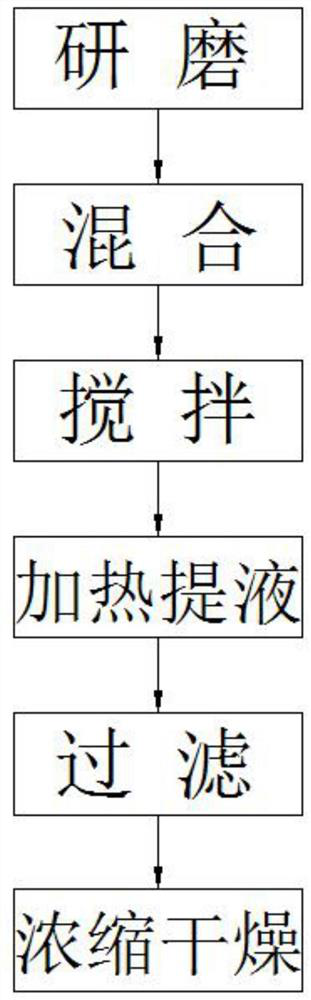

Image

Examples

Embodiment 1

[0024] The probiotic stachyose listed in this example consists of the following components in weight percentage: Lactobacillus acidophilus powder 3%, Lactobacillus casei powder 4%, Bifidobacterium powder 6%, amino acid tablets 20%, water Throose 40%.

[0025] It is made according to the following method. First, use a grinder to grind the amino acid flakes into powder, and then put the ground material, Lactobacillus acidophilus powder, Lactobacillus casei powder, Bifidobacterium powder and stachyose into a container , And then add clean water to the container to mix the above-mentioned materials, then use the mixing equipment to stir the mixed materials to fully mix the materials, and then use the heating equipment to heat the stirred materials , And extract the juice in the heated water to obtain the sugar liquid, and then use the filter to filter the impurities in the material after the heated extract, and then the sugar liquid after filtering the impurities is first concentrate...

Embodiment 2

[0028] The probiotic stachyose listed in this example is composed of the following components in weight percentage: Lactobacillus acidophilus powder 4.5%, Lactobacillus casei powder 6%, Bifidobacterium powder 7%, amino acid tablets 22.5%, water Throose 44%.

[0029] It is made according to the following method. First, use a grinder to grind the amino acid flakes into powder, and then put the ground material, Lactobacillus acidophilus powder, Lactobacillus casei powder, Bifidobacterium powder and stachyose into a container , And then add clean water to the container to mix the above-mentioned materials, and then use the mixing equipment to stir the mixed materials to fully mix the materials, and then use the heating equipment to heat the stirred materials , And extract the juice in the heated water to obtain the sugar liquid, and then use the filter to filter the impurities in the material after the heated extract, and then the sugar liquid after filtering the impurities is first ...

Embodiment 3

[0032] The probiotic stachyose listed in this embodiment consists of the following components in weight percentage: Lactobacillus acidophilus powder 6%, Lactobacillus casei powder 8%, Bifidobacterium powder 8%, amino acid tablets 25%, water Throose 48%.

[0033] It is prepared according to the following method. Firstly, use a grinder to grind the amino acid flakes into powder, and then put the ground material, Lactobacillus acidophilus powder, Lactobacillus casei powder, Bifidobacterium powder and stachyose into a container , And then add clean water to the container to mix the above-mentioned materials, then use the mixing equipment to stir the mixed materials to fully mix the materials, and then use the heating equipment to heat the stirred materials , And extract the juice in the heated water to obtain the sugar liquid, and then use the filter to filter the impurities in the material after the heated extract, and then the sugar liquid after filtering the impurities is first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com