Functional amino acid enzyme and preparation method thereof

An amino acid and enzyme technology, applied in the field of bioengineering, can solve problems such as high operating costs and product risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

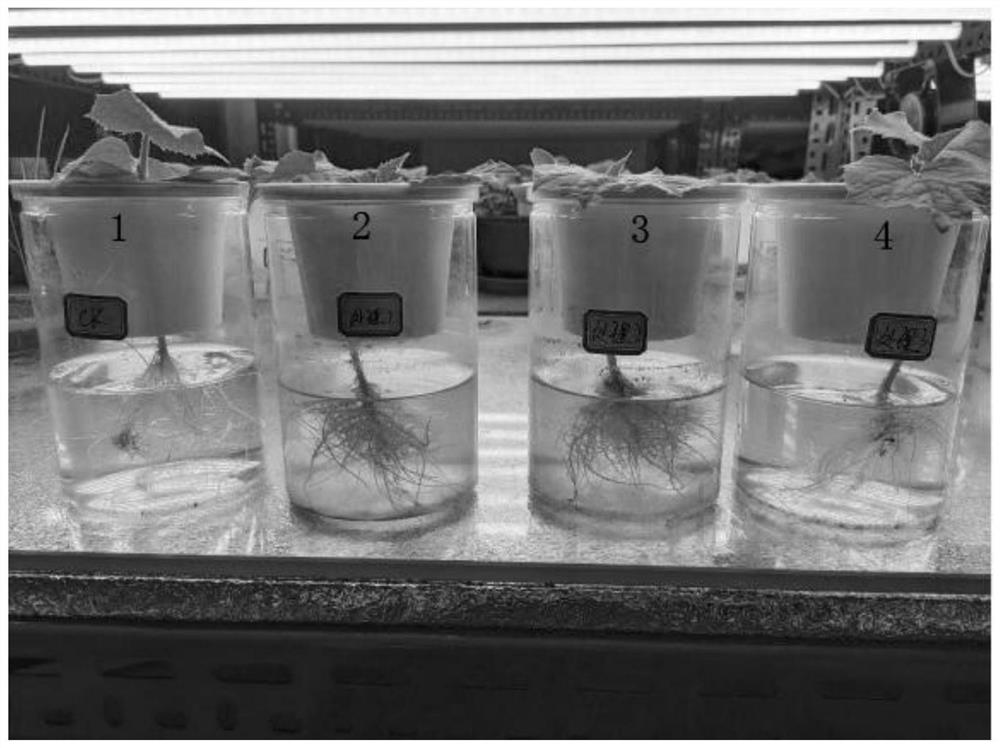

Image

Examples

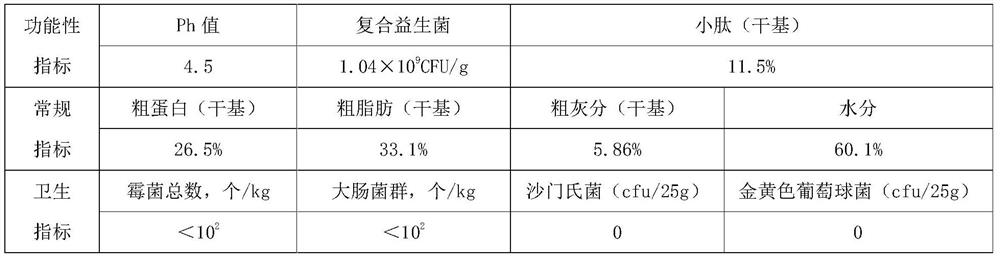

Embodiment 1

[0047] Put 1000kg of slaughtered chicken intestines into the crushing device, carry out crushing treatment, and crush the material to below 20 orders. Then transport to the mincing device for mincing treatment, mincing to below 100 mesh. The crushed material is sterilized at 100°C for 1 hour. Stir continuously during the sterilization process, and the stirring frequency is 3r / min. Add 1% glucose by mass to the sterilized material, and cool down to 50°C. After cooling down, add 0.1% compound enzyme preparation (0.5 part of acid protease and 0.5 part of lipase), stir the enzymolysis for 3 hours, stirring frequency 5r / min, and adjust the pH value in the scope of 6.0~7.0. The prepared slurry is then transported to an aerobic fermentation container, inoculated with 0.1% special fermenter A agent (0.3 part of Bacillus subtilis, 0.7 part of Bacillus licheniformis and 1.0 part of Saccharomyces cerevisiae), the stirring frequency is 5r / min, and the Into the air 0.4VVm, fermentation ...

Embodiment 2

[0051] Put 1000kg of the slaughtered chicken skeleton into the crushing device, carry out crushing treatment, and crush the material to below 20 orders. Then transport to the mincing device for mincing treatment, mincing to below 100 mesh. The minced material is sterilized. The sterilization temperature is 90°C, and the sterilization time is 1 hour. Stir continuously during the sterilization process, and the stirring frequency is 5r / min. Add 2% mass of glucose to the sterilized material, and cool down to 45°C. After cooling down, add 0.2% compound enzyme preparation (0.7 part of acid protease and 0.3 part of lipase), stir the enzymolysis for 3 hours, stirring frequency 5r / min, and adjust the pH value in the scope of 6.0~7.0. The prepared slurry was transported to an aerobic fermentation container, inoculated with 0.1% special fermentation bacteria A agent (0.3 parts of Bacillus subtilis, 0.3 parts of Bacillus licheniformis and 1.5 parts of Saccharomyces cerevisiae), and the...

Embodiment 3

[0055] Put 1000kg of processed aquatic fish offal into the crushing device for crushing treatment, and crush the material to below 20 mesh. Then the material is sent to the crushing device for crushing treatment, and the crushing is below 100 mesh. The minced material is sterilized, the sterilization temperature is 80°C, and the sterilization time is 1 hour. Stir continuously during the sterilization process, and the stirring frequency is 5r / min. Add 2% glucose by mass to the sterilized material, and cool down to 55°C. After cooling down, add 0.3% compound enzyme preparation (0.4 part of acid protease and 0.6 part of lipase), stir and enzymolyze for 3 hours, stirring frequency 5r / min, and adjust the pH value in the scope of 6.0~7.0. Transfer the slurry prepared in the step to an aerobic fermentation container, inoculate with 0.1% special fermentation bacteria A agent (0.6 parts of Bacillus subtilis, 0.6 parts of Bacillus licheniformis and 0.8 parts of Saccharomyces cerevisia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com