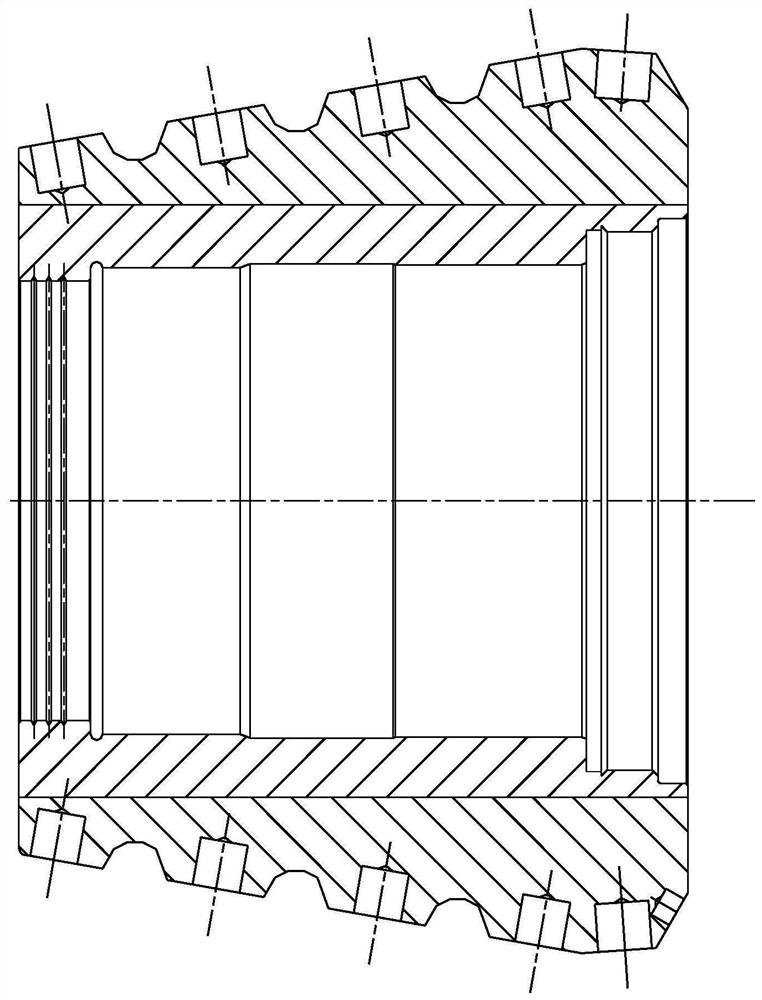

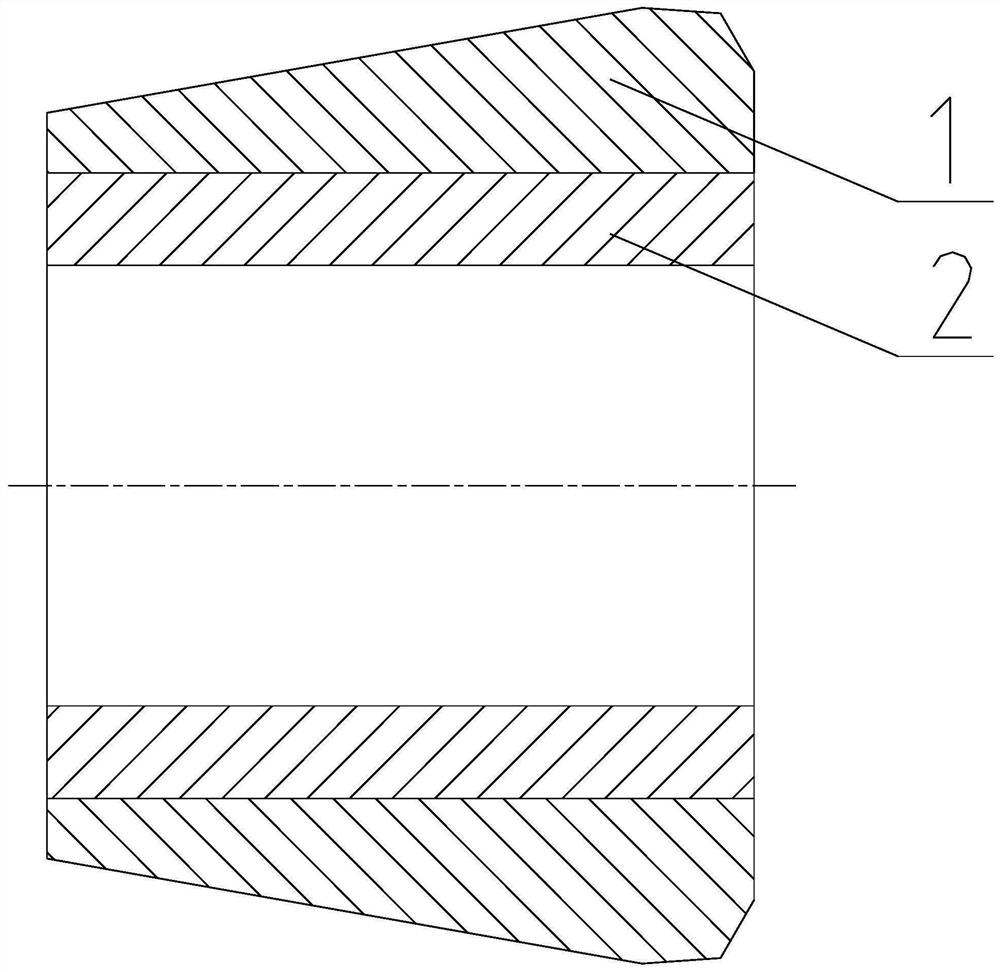

Centrifugal casting process for rare earth wear-resistant alloy steel rock-breaking hob shell

A centrifugal casting, alloy steel technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of large wear force, high wear degree, and hob shell wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

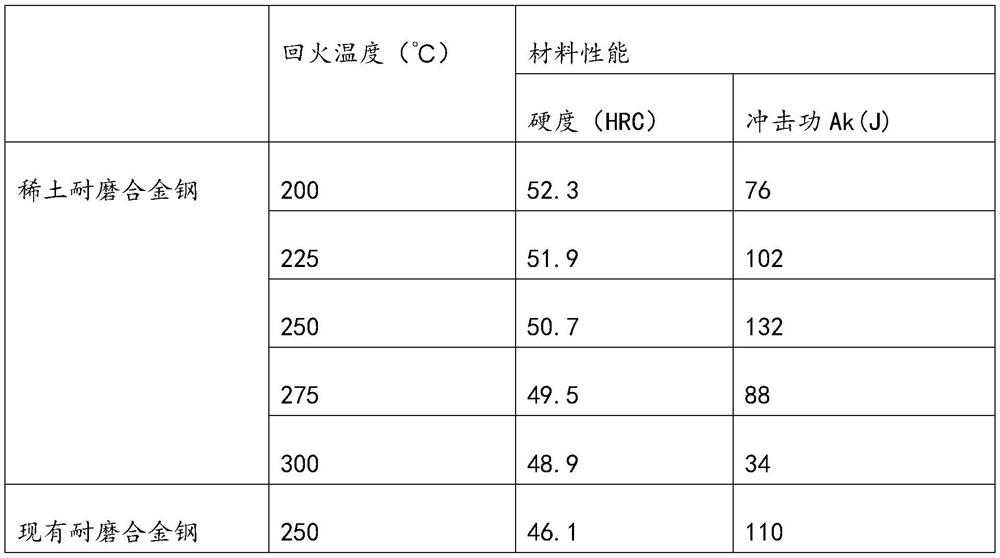

Examples

Embodiment Construction

[0035] The centrifugal casting process of the rare earth wear-resistant alloy steel rock-breaking hob shell in this embodiment includes the following steps:

[0036] (1) Molding: Using the shell casting method, on the molding machine, use 70-140 mesh separately prepared coated sand with high temperature resistance and high strength and hardness, and make the shell according to the corresponding mold of the designed size.

[0037] (2) Shell repair: Repair the pressed shell to remove flash and burrs.

[0038] (3) Brush paint: evenly spray high-temperature-resistant zircon paint on all contact surfaces with molten steel.

[0039] (4) Form shell assembly: put the shell after drying the paint into the centrifuge mold, put 2-3 layers of asbestos boards with pouring holes on the outermost layer, and finally press and pin the outer end cover of the centrifuge mold Good steel pin.

[0040] (5) Melting molten steel: a furnace of rare earth wear-resistant alloy steel is smelted, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com