3D printing bone tissue engineering stent with slow release and osteogenesis promoting functions and preparation method and application of 3D printing bone tissue engineering stent

A tissue engineering scaffold and 3D printing technology, applied in the field of biomedical materials, can solve the problems of slow healing of bone tissue and poor osteogenic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

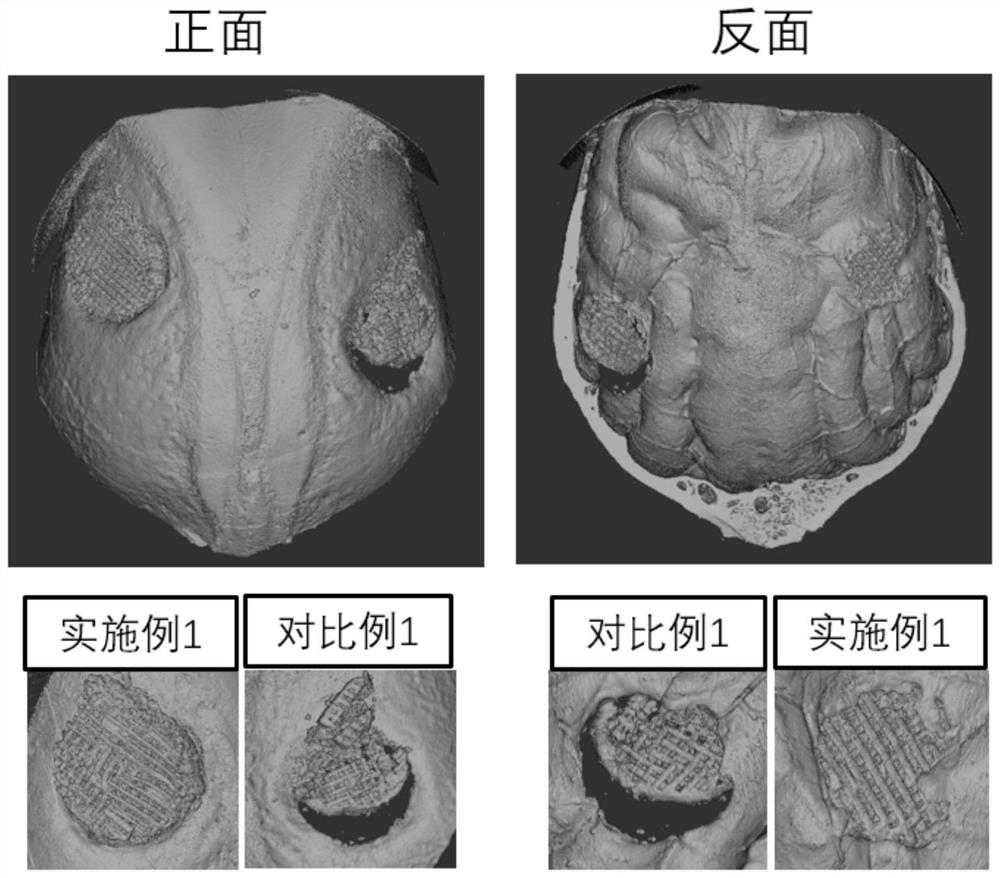

Embodiment 1

[0047] (1) Preparation of 3D printing ink

[0048] In a water bath at 30°C, add sodium alginate powder material to deionized water to prepare a 6% sodium alginate solution, add 1ml of icariin-dimethyl sulfoxide solution with a concentration of 0.1g / ml, and use a magnetic Mix it well with a mixer until smooth. After preheating at 50°C for 30-60 minutes, reduce the viscosity of the sodium alginate solution, then slowly add the solid calcium phosphate powder into the preheated solution, and mix the slurry evenly with a homogeneous mixer until no phosphoric acid is observed Calcium agglomerates. The mass ratio of calcium phosphate, sodium alginate, icariin and deionized water in the final slurry is 25:6:0.08:100. This mixed slurry is used as 3D printing ink.

[0049] (2) printing support

[0050] The three-dimensional model of the scaffold was designed by 3D modeling software, and the mixed ink was printed into a calcium phosphate scaffold with a first-level macroporous structur...

Embodiment 2

[0062] The 3D printed bone tissue engineering scaffold material was prepared with reference to the method described in Example 1, which differs from Example 1 in that the mass ratio of calcium phosphate, sodium alginate, icariin and deionized water was adjusted to 25:6 : 0.04: 100, all the other processing methods are the same as those described in Example 1. The experimental results show that the obtained scaffold has a slow-release function and an osteogenesis-promoting effect, but compared with Example 1, due to the lower solid content of icariin in the printing paste, bone tissue with slow-release and osteogenesis-promoting functions The total drug loading of the engineering scaffold is less, and the osteogenesis-promoting function of the scaffold obtained in this embodiment on bone defects is better than that of Comparative Example 1, but slightly worse than that of Example 1.

Embodiment 3

[0064] The 3D printed bone tissue engineering scaffold material was prepared with reference to the method described in Example 1, which differs from Example 1 in that the mass ratio of calcium phosphate, sodium alginate, icariin and deionized water was adjusted to 25:6 : 0.16: 100, all the other processing methods are the same as those described in Example 1. The experimental results show that the obtained scaffold has slow-release function and osteogenesis-promoting effect. Since the solid content of icariin in the printing slurry is more than that of Examples 1 and 2, the bone tissue engineering scaffold with slow-release and osteogenesis-promoting function The total amount of drug loaded is more, and the bone defect-promoting function of the scaffold obtained in this embodiment is better than that of Examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com