Novel melt-blown non-woven fabric and manufacturing method and production equipment thereof

A technology of meltblown nonwovens and production equipment, which is applied in nonwovens, rayon manufacturing, melt spinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

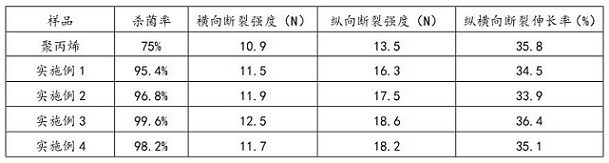

Embodiment 1

[0047] S01. Use silicon dioxide as the functional particle, and dry it in a vacuum oven at 80°C for 12 hours in advance. Weigh 100 parts of silicon dioxide particles, 1 part of polyethylene wax dispersant, and 1 part of The KH550 coupling agent was added into an ultrasonic reactor with an ultrasonic frequency of 25khz, subjected to ultrasonic modification for 30min, and then taken out and dried at a drying temperature of 80°C and a drying time of 10 h to obtain the modified silica particles ;

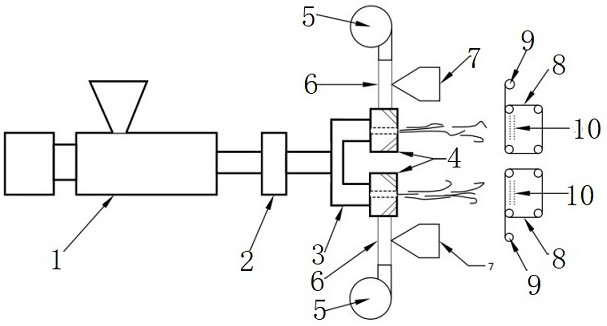

[0048] S02. Pre-dry the polypropylene resin particles in a vacuum drying oven at 80°C for 12 hours, and then weigh 99% of the polypropylene resin particles and 1% of the modified silica functional particles according to the mass fraction and add them to a rotating speed of 1500~ Mix in a mixer at 2000r / min, put the compound into the hopper of the twin-screw extruder (1), and melt it in the screw extruder (1);

[0049] S03. After being filtered by the filter device (2), it is diverted b...

Embodiment 2

[0052] The difference with embodiment 1 is:

[0053] 1. Add 100 parts of activated carbon particles, 4 parts of OP-10 dispersant, and 6 parts of KH560 coupling agent into the ultrasonic reactor with an ultrasonic frequency of 25khz according to the mass fraction of the modified functional particles, carry out ultrasonic modification for 50min, and then take it out drying, the drying temperature is 80°C, and the drying time is 8 h, to obtain the modified activated carbon particles;

[0054] 2. Polylactic acid particles are used as resin particles, and 94% polylactic acid resin particles and 6% modified activated carbon particles are used as raw materials according to the mass fraction.

Embodiment 3

[0056] The difference with embodiment 1 is:

[0057] 1. Add 100 parts of zeolite particles, 2 parts of OP-10 dispersant and 4 parts of KH560 coupling agent into the ultrasonic reactor with ultrasonic frequency of 25khz according to the mass fraction of modified functional particles, carry out ultrasonic modification for 50min, and then take out drying, the drying temperature is 80°C, and the drying time is 6 h, to obtain the modified zeolite particles;

[0058] 2. Polylactic acid particles are used as resin particles, and 96% polylactic acid resin particles and 4% modified zeolite particles are used as raw materials according to the mass fraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com