Polyimide aerogel fiber as well as preparation and application thereof

An aerogel fiber, polyimide technology, applied in the chemical characteristics of fibers, textiles and papermaking, one-component synthetic polymer rayon, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

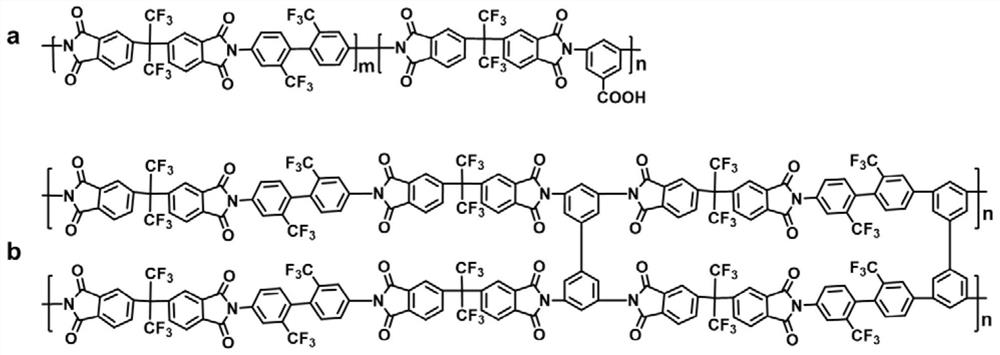

[0043](1) Under nitrogen protection, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (TFMB, 6.4046g), 3,5-diaminobenzoic acid into a 250mL three-necked flask (DABA, 3.0229g) then add 150ml N-methylpyrrolidone (NMP), mechanically stir until TFMB and DABA are dissolved or evenly suspended in NMP, then add 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA , 17.7696g), after 36h of ice-water bath reaction, the temperature was raised to 190°C, and the reaction was carried out for 8h to obtain soluble polyimide. (Among them, 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl, Bid Pharmaceuticals, has a purity of 98%; 3,5-diaminobenzoic acid, Anaiji Chemical Reagent, has a purity of 98%; N-Methylpyrrolidone, Sinopharm Reagent, 98%; 4,4'-(Hexafluoroisopropene) diphthalic anhydride, Leyan Reagent, purity 97%)

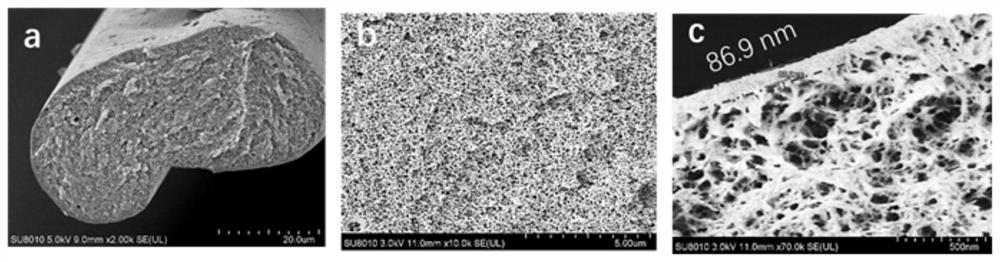

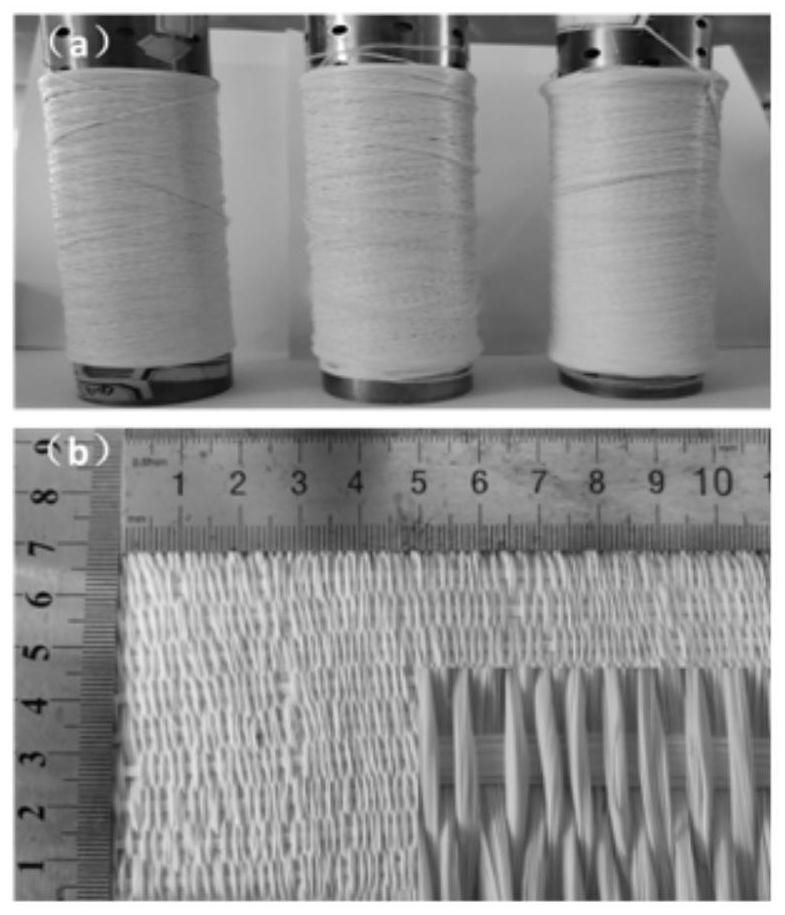

[0044] (2) The spinning dope in step (1) is subjected to a wet spinning process, using water as a coagulation bath, the temperature is 10° C., the spinning speed is 5 m / min, ...

Embodiment 2

[0050] (1) Under nitrogen protection, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (TFMB, 6.4046g), 3,5-diaminobenzoic acid into a 250mL three-necked flask (DABA, 3.0229g) then add 150ml N-methylpyrrolidone (NMP), mechanically stir until TFMB and DABA are dissolved or evenly suspended in NMP, then add 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA , 17.7696g), after 36h of ice-water bath reaction, the temperature was raised to 190°C, and the reaction was carried out for 8h to obtain soluble polyimide.

[0051] (2) The spinning dope in step (1) is subjected to a wet spinning process, using water as a coagulation bath, the temperature is 25°C, the spinning speed is 3m / min, and the winding speed is 5.5m / min.

[0052] (3) Place the polyimide fiber in step (2) in water for 48 hours to age.

[0053] (4) Place the polyimide fiber in step (3) in a freeze dryer, and freeze-dry at -80° C. and 20 Pa for 48 hours. That is, the polyimide airgel fiber is prepared.

[0054] ...

Embodiment 3

[0057] (1) Under nitrogen protection, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (TFMB, 6.4046g), 2-(4-aminophenyl )-5-aminobenzimidazole (BIA, 2.1628g), then add 150ml N-methylpyrrolidone (NMP), mechanically stir until TFMB and DABA are dissolved or evenly suspended in NMP, then add 4,4'-(hexafluoro Isopropylene) diphthalic anhydride (6FDA, 17.7696g), after 36 hours of reaction in an ice-water bath, the temperature was raised to 190°C, and the reaction was carried out for 8 hours to obtain a soluble polyimide.

[0058] (2) The spinning dope in step (1) is subjected to a wet spinning process, using water as a coagulation bath, the temperature is 50° C., the spinning speed is 5 m / min, and the winding speed is 5.5 m / min.

[0059] (3) Place the polyimide fiber in step (2) in water for 48 hours to age.

[0060] (4) Place the polyimide fiber in step (3) in a freeze dryer, and freeze-dry at -80° C. and 20 Pa for 48 hours. That is, the polyimide airgel fiber is prepared.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com