Impregnating compound for improving aging resistance of alumina continuous fibers, and preparation method and application thereof

A technology of continuous fiber and sizing agent, applied in the field of surface modification of inorganic ceramic fibers, can solve the problems of unsatisfactory improvement effect of fiber service cycle, inability to increase fiber wear resistance and mechanical properties, and insignificant anti-aging effect, and achieve good clustering. performance and lubricity, increased mechanical properties, low static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: A preparation process of a sizing agent for improving the aging resistance of alumina continuous fibers:

[0032] S1: dilute 0.5-2wt% polyvinyl butyral resin with 15-25 times of organic solvent, and stir for 0.5-2 hours;

[0033] S2: dilute 0.5-2wt% lubricant with 15-25 times of organic solvent, and stir for 0.5-2 hours;

[0034] S3: Dissolving 0.05-0.2wt% antistatic agent with 15-25 times of organic solvent, stirring time is 0.5-2h;

[0035]S4: The solutions in steps S1, S2, and S3 are sequentially added to the remaining organic solvent, mixed evenly, and stirred for 1-2 hours to obtain the sizing agent for improving the aging resistance of the alumina continuous fiber.

[0036] It can be understood that the properties of the PVB used are: the butyral content in the polyvinyl butyral resin is 45-50wt%, and the viscosity is 15-18mPa . s. The molecular weight is 280-310.

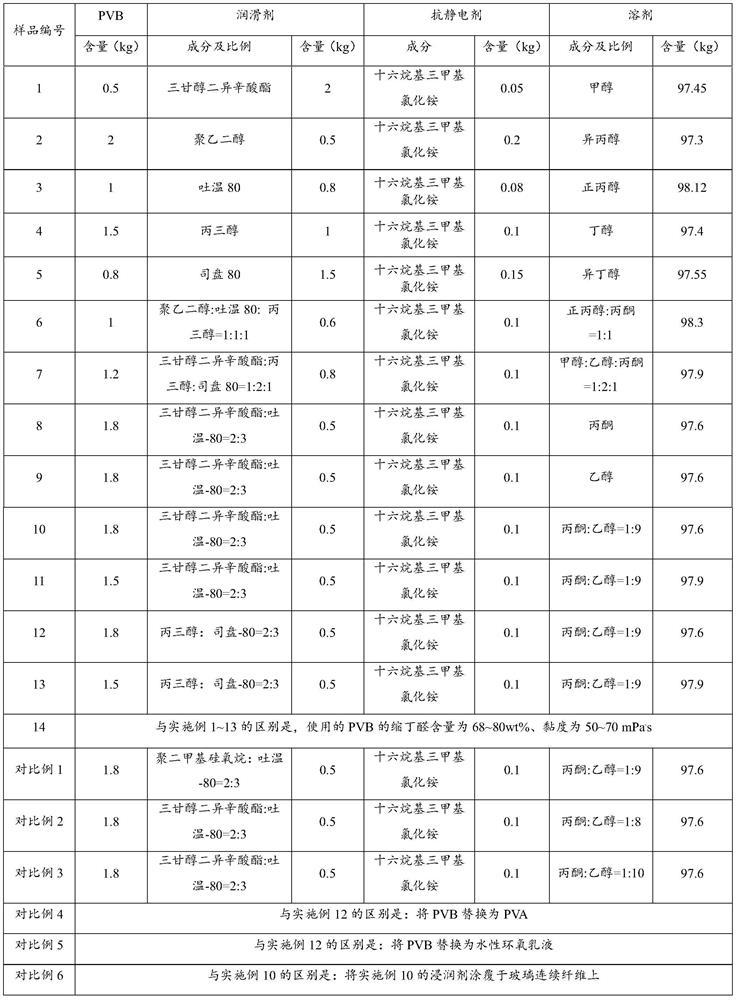

[0037] It can be understood that the mass percentages of all material components in t...

Embodiment 2

[0040] Example 2: Characterization:

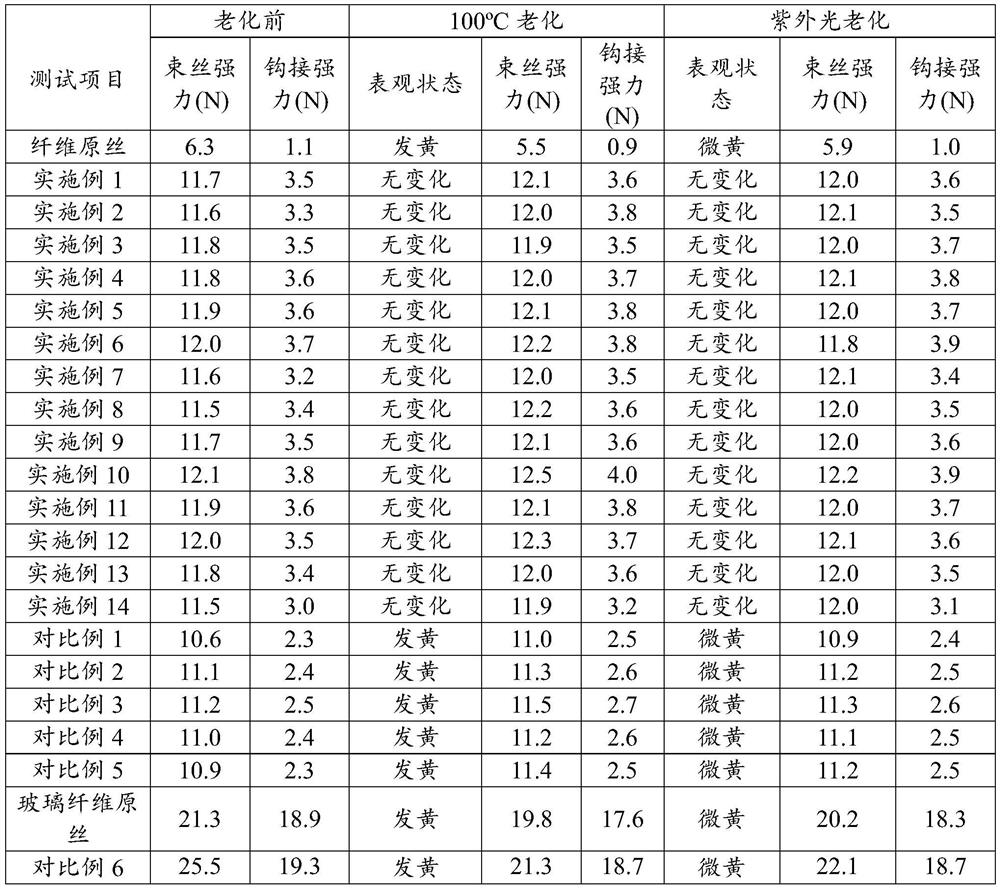

[0041] The sizing agents in Example 1 were coated on the surface of the alumina continuous fibers at a coating rate of 1.4-1.9 wt%. Performance tests were performed on the continuous fibers coated with the sizing agents. The test results are shown in Table 1 below.

[0042] In this example, the performance of alumina continuous fibers after coating the sizing agent on the alumina continuous fiber precursors, and the performance of alumina continuous fibers (including fiber precursors and fibers coated with sizing agent) after aging at 100°C were tested respectively. Fiber properties, fiber properties after ultraviolet aging of alumina continuous fibers (including fiber precursors and fibers coated with sizing agent).

[0043] It can be understood that the alumina continuous fibers used in each embodiment are the same batch of finished fibers.

[0044] It can be understood that the aging method of alumina continuous fiber coated with sizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com