Carbon-carbon composite material as well as preparation process and application thereof

A carbon-carbon composite material and carbonization technology, applied in the field of parts and components, can solve the problems of short life, less ash, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A carbon-carbon composite material preparation process, including preform preparation, impregnating agent raw material preparation, multi-stage densification reaction; preform preparation includes the following steps:

[0043] S1. Green body preparation: Weave carbon fiber into a three-dimensional braided body according to the product structure to obtain a carbon fiber braided body with a volume density of 0.3-0.6g / cm 3 ;

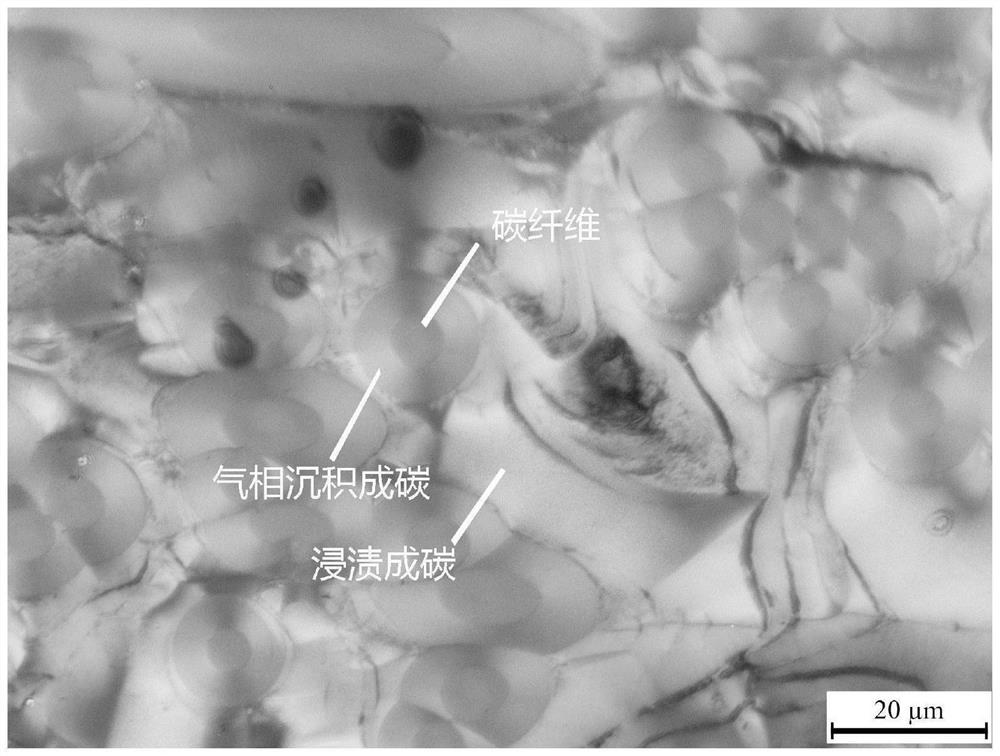

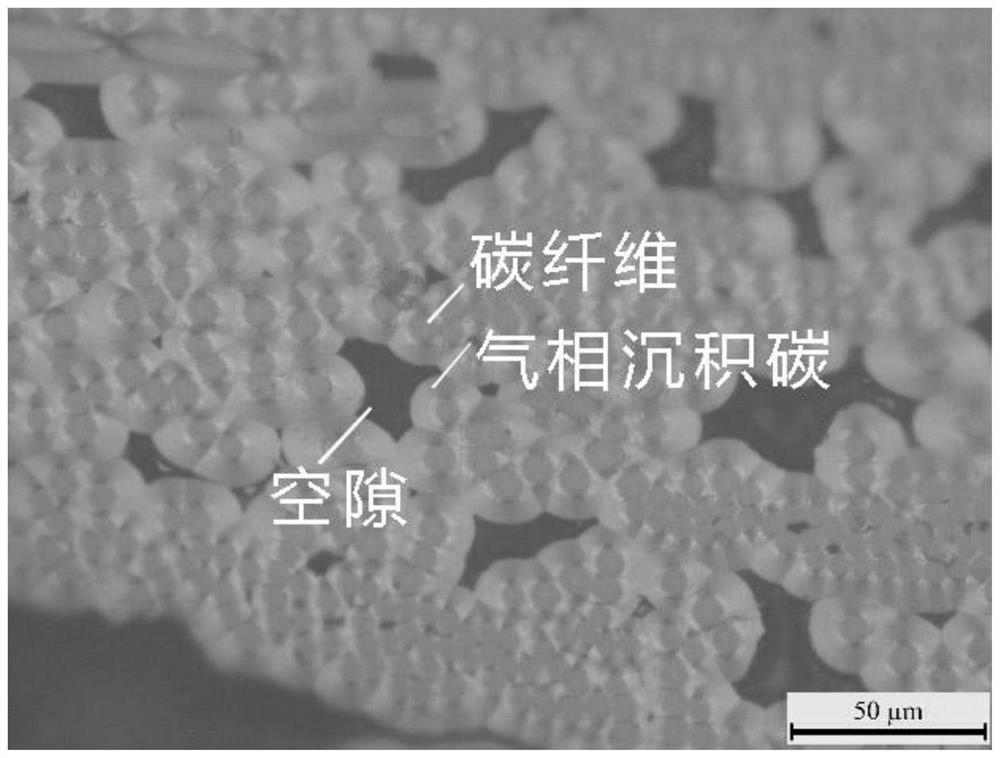

[0044] S2. Chemical vapor deposition: 83-88% of natural gas and 12-17% of nitrogen are introduced into the closed reaction furnace, the pressure in the furnace is controlled at 1-5KPa, the temperature is 1050-1150°C, and the time is 70-130h, and the carbon fiber braided body Carry out chemical vapor deposition to obtain a density of 0.9-1.3g / cm 3 Preforms with vapor-deposited carbon;

[0045] Preparation of impregnating agent raw materials:

[0046] S3. Mix ethylene tar and hydrogenating agent in a ratio of 2:1 to 3 by weight and add it to the react...

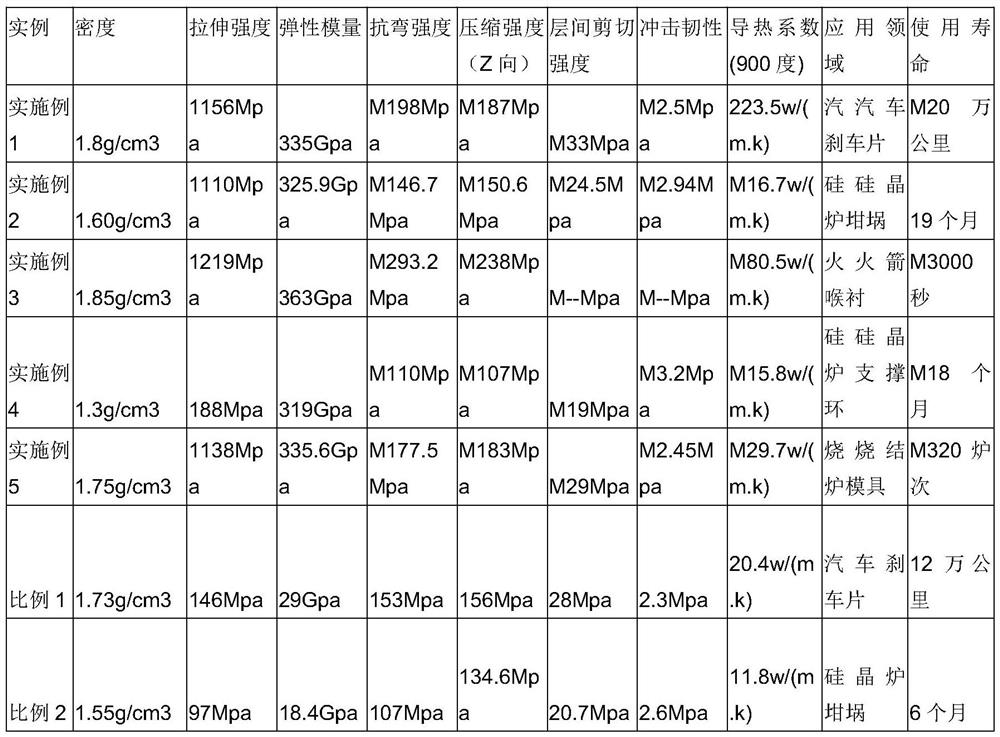

Embodiment 1

[0056] A carbon-carbon composite material, the carbon-carbon composite material includes 28% of carbon fiber, 38% of vapor deposited carbon, and 34% of impregnated carbon by mass.

[0057] The carbon fiber is a modified carbon fiber, and the modification process of the carbon fiber is as follows: heating the carbon fiber to 800°C in an inert gas containing less than 2% oxygen, keeping it warm for 3.0h, and then cooling it to room temperature in the inert gas, and then the carbon fiber Put in concentrated nitric acid with a concentration of 45% to oxidize for 1.5 hours, wash with deionized water to pH=7, then dry in the air, and finally coat and dry with a silane coupling agent with a concentration of 4.5%.

[0058] The impregnated carbon is obtained by reacting an impregnating agent, and the impregnating agent is a polymer obtained by reacting ethylene tar and a hydrogenating agent in a ratio of 1:1 by weight.

[0059] The hydrogenating agent is tetrahydronaphthalene, tetrahyd...

Embodiment 2

[0074] A carbon-carbon composite material, the carbon-carbon composite material includes, by mass, 25.64% of carbon fiber, 33.77% of vapor-deposited carbon, and 43.59% of impregnated carbon.

[0075] The carbon fiber is a modified carbon fiber, and the modification process of the carbon fiber is as follows: heating the carbon fiber to 600°C in an inert gas containing less than 2% oxygen, keeping it warm for 3.0h, and then cooling it to room temperature in the inert gas, and then the carbon fiber Put in concentrated nitric acid with a concentration of 45% to oxidize for 1 hour, wash with deionized water to pH=7, then dry in the air, and finally coat and dry with a silane coupling agent with a concentration of 2%.

[0076] The impregnated carbon is obtained by reacting an impregnating agent, which is a polymer obtained by reacting ethylene tar and a hydrogenating agent in a ratio of 2:1 by weight.

[0077] The hydrogenating agent is tetrahydronaphthalene, NaBH4, i-Bu2AlH.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com